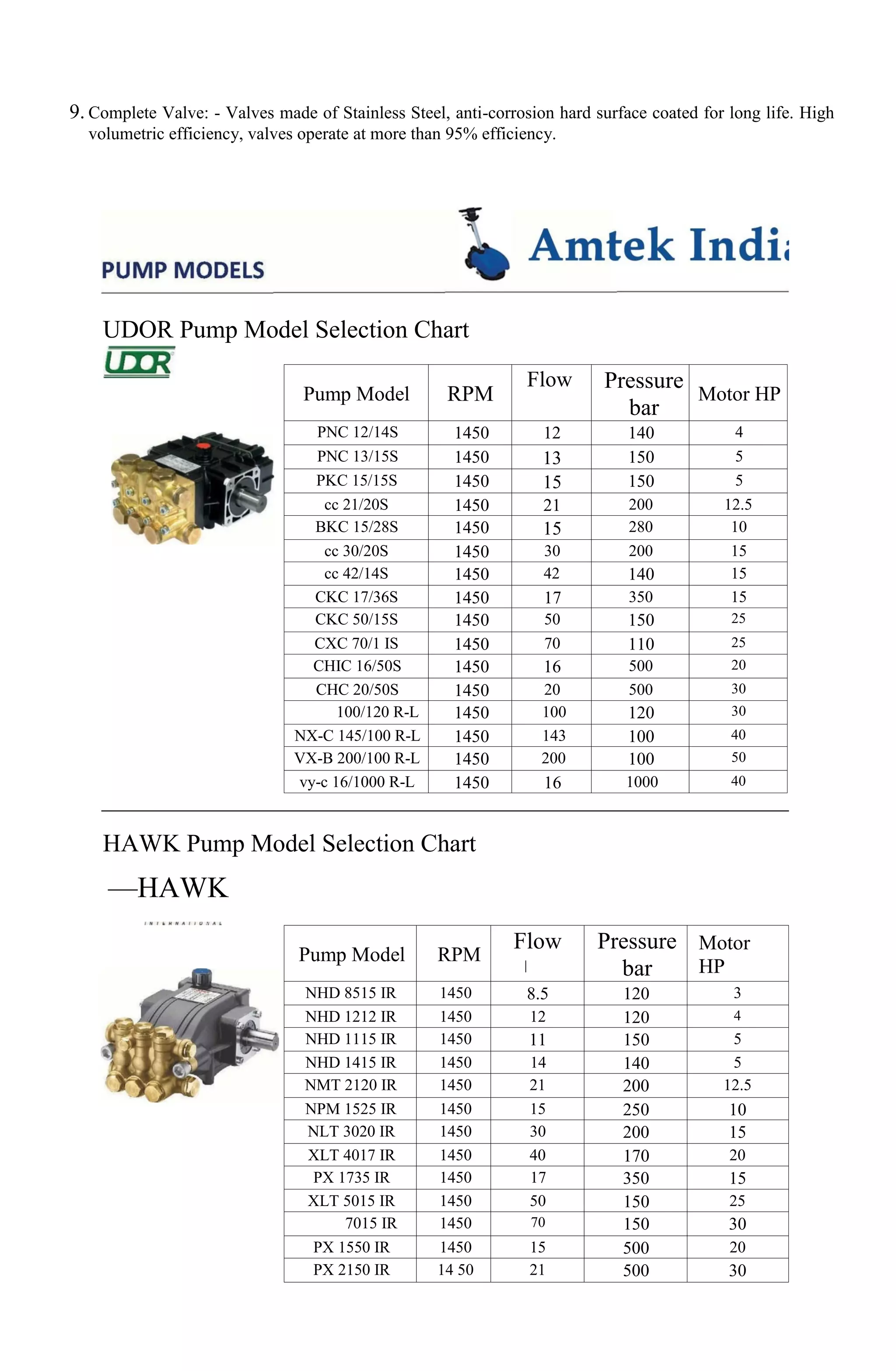

Amtek India specializes in high-pressure triplex plunger pumps and is part of the SSI-I group with over 16 years of manufacturing experience. The company is an authorized partner of Hawk and offers custom-made high-pressure cleaning systems tailored to customer specifications. Their products feature advanced engineering and materials, ensuring durability and high efficiency, suitable for various industrial applications.