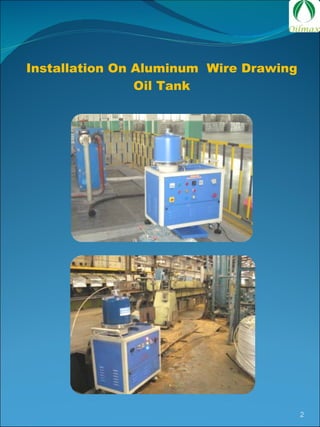

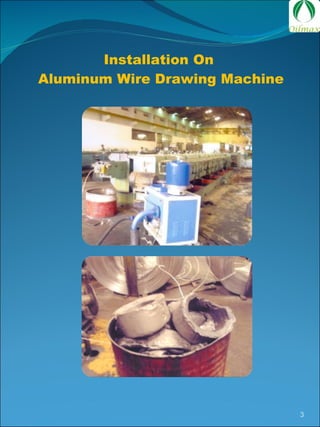

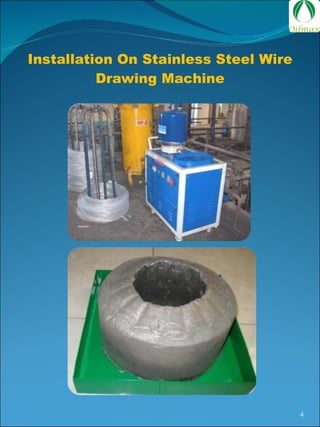

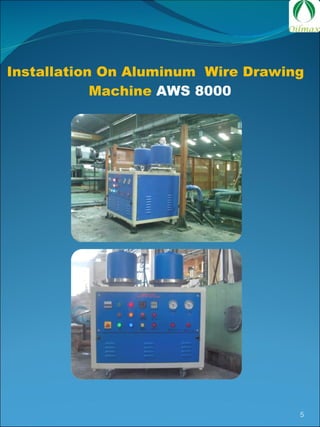

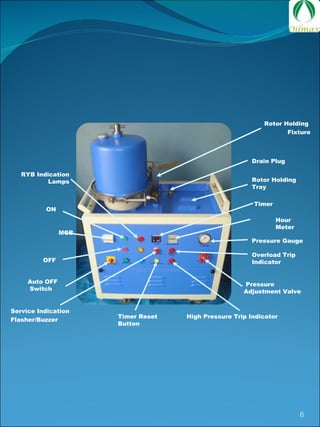

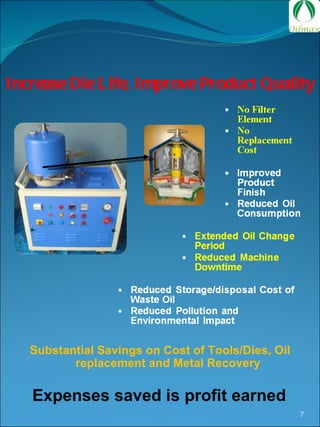

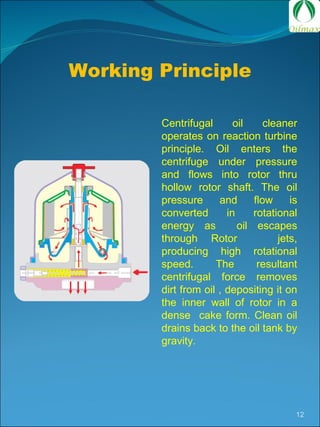

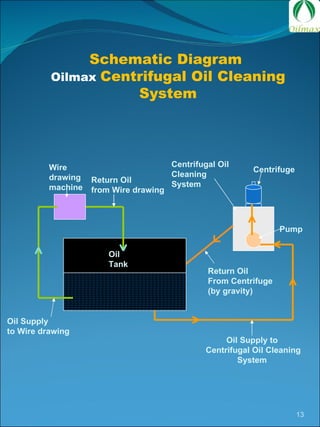

The document describes a centrifugal oil cleaner system that can be installed on various wire and tube drawing machines and applications. It removes metallic sludge from drawing oils, increasing die life, improving product quality, and reducing costs. Key benefits include no replacement elements needed, increased oil life, reduced oil consumption and machine downtime, and substantial savings on oil replacement costs. It works by using centrifugal force to separate sludge from oil inside a high-speed rotor, with clean oil returning to the tank by gravity.