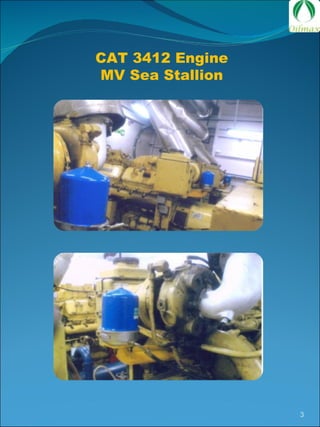

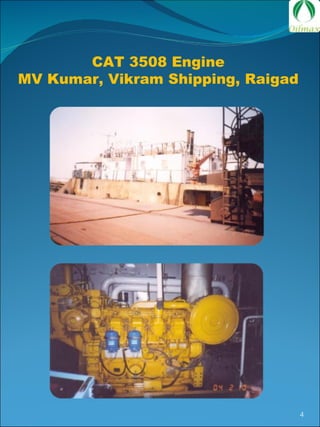

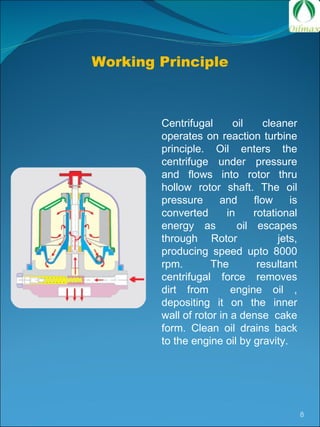

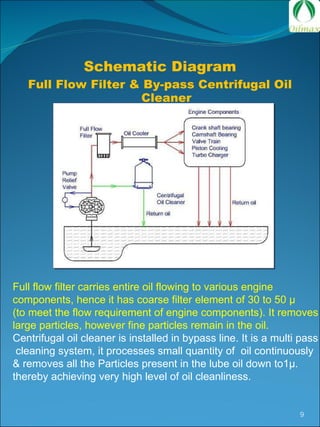

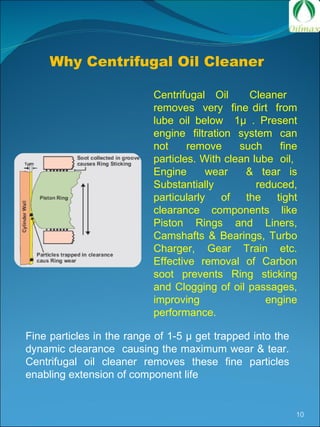

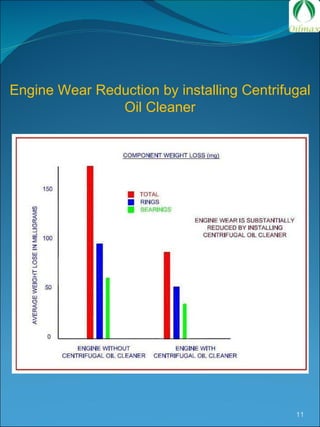

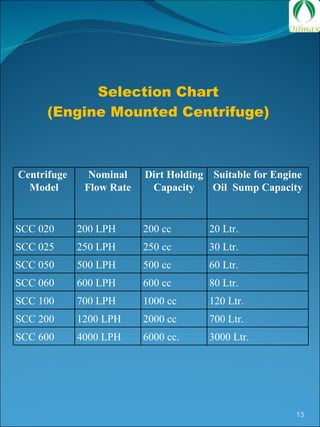

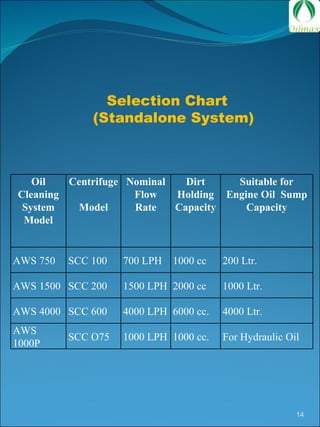

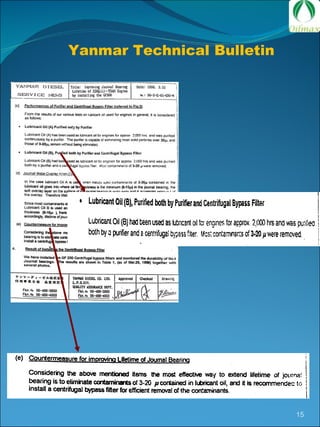

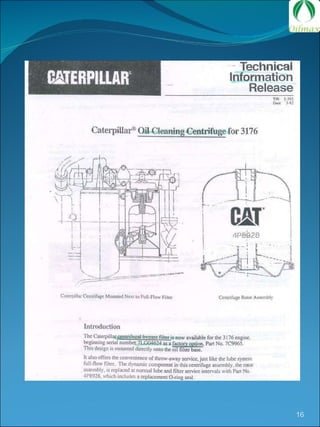

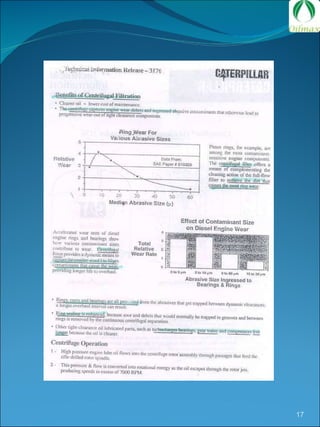

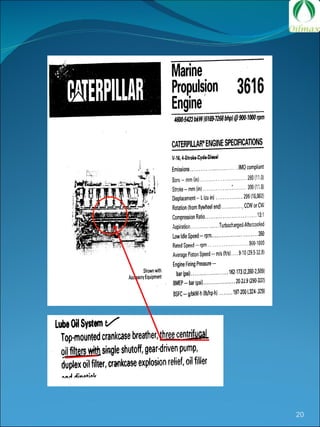

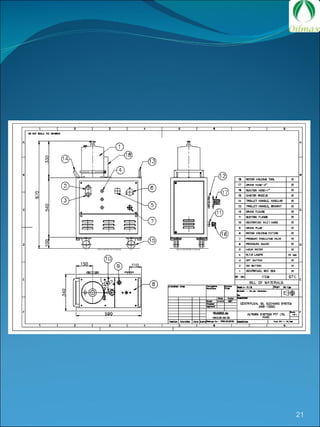

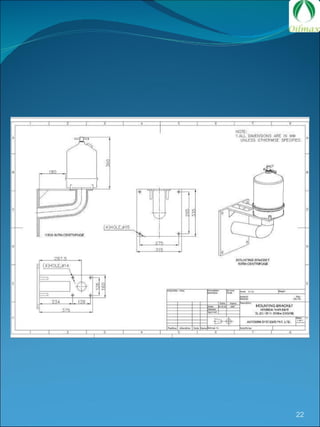

The document details the operation and benefits of a centrifugal oil cleaner designed for Caterpillar engines, explaining its mechanism of filtering engine oil to remove fine particles below 1μ, which traditional systems cannot achieve. It emphasizes that the cleaner not only reduces engine wear and tear but also extends component life, improves engine performance, and lowers maintenance costs. Additionally, it provides specifications and applications for various centrifuge models suited for different engine oil sump capacities.