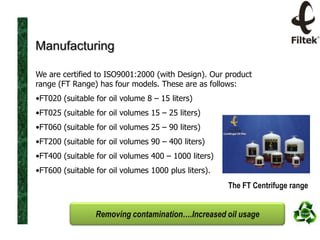

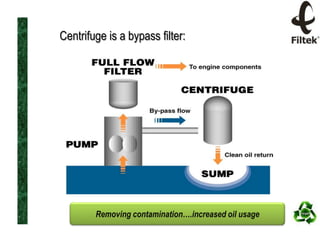

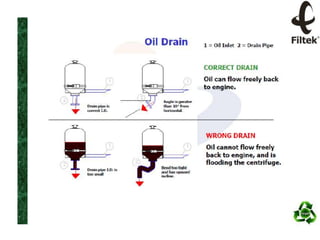

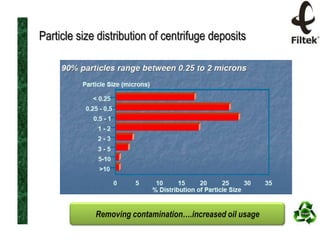

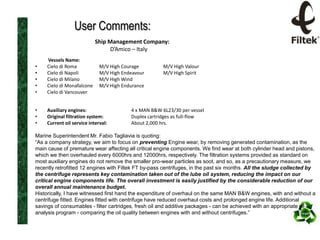

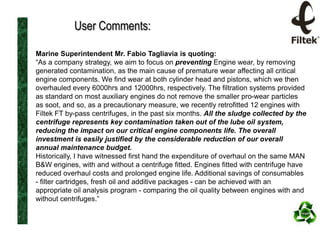

Filtek provides lube oil filtration solutions for the marine industry, including centrifugal oil filters ranging from models suitable for oil volumes of 8-1000 liters; it discusses Filtek's product offerings and customer testimonials praising their filters' ability to remove harmful contaminants and extend engine life, reducing maintenance costs.