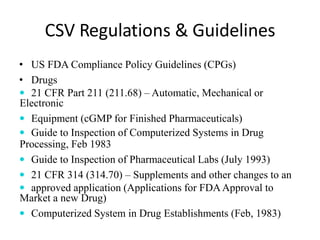

The document discusses computerized system validation and electronic records requirements. It provides an overview of US FDA regulations regarding computerized systems including 21 CFR Part 11, which establishes criteria for electronic records and electronic signatures. It also discusses concepts like closed and open systems, audit trails, electronic signatures, and the Good Automated Manufacturing Practice (GAMP) guidelines for computer system validation.