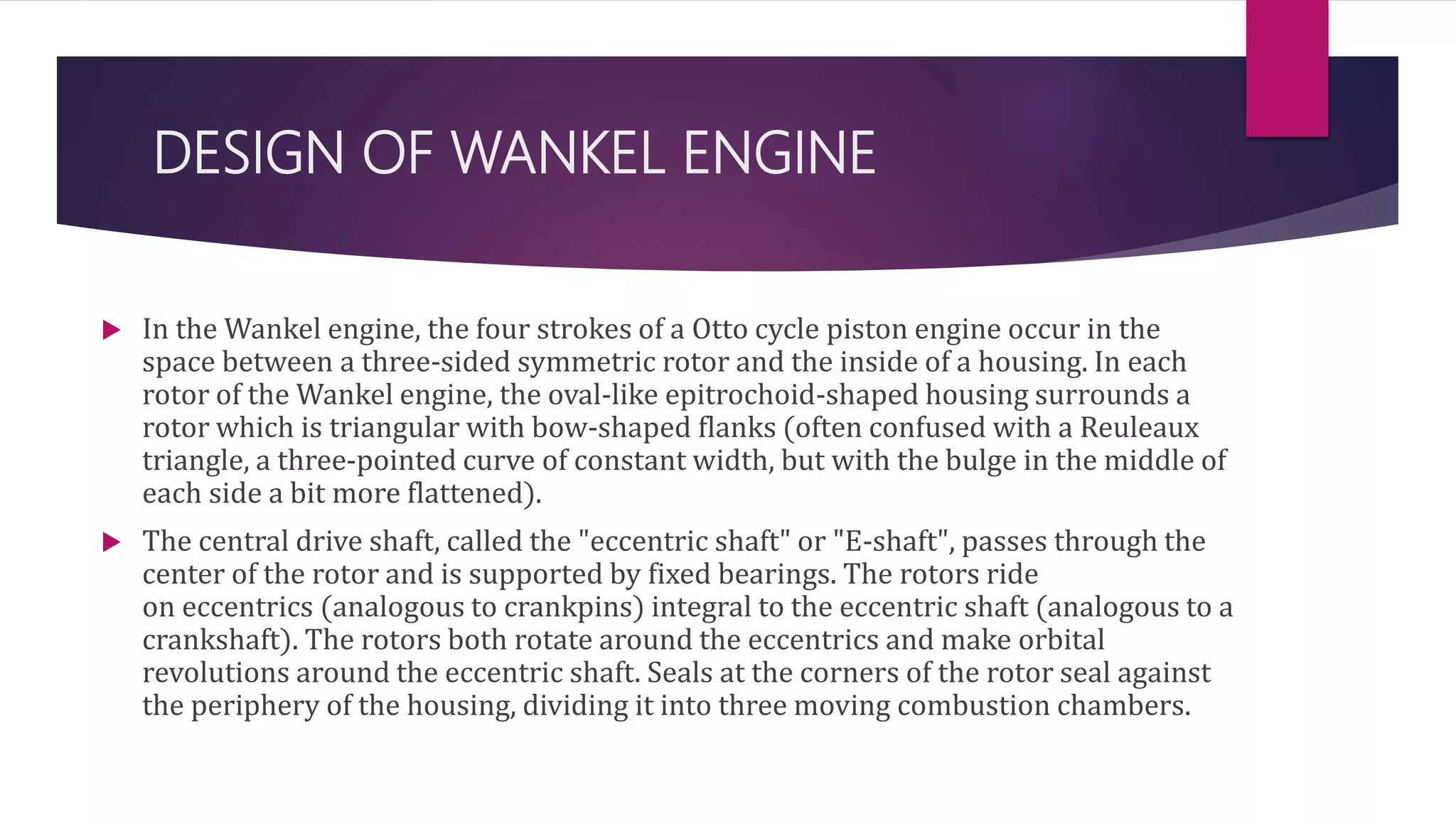

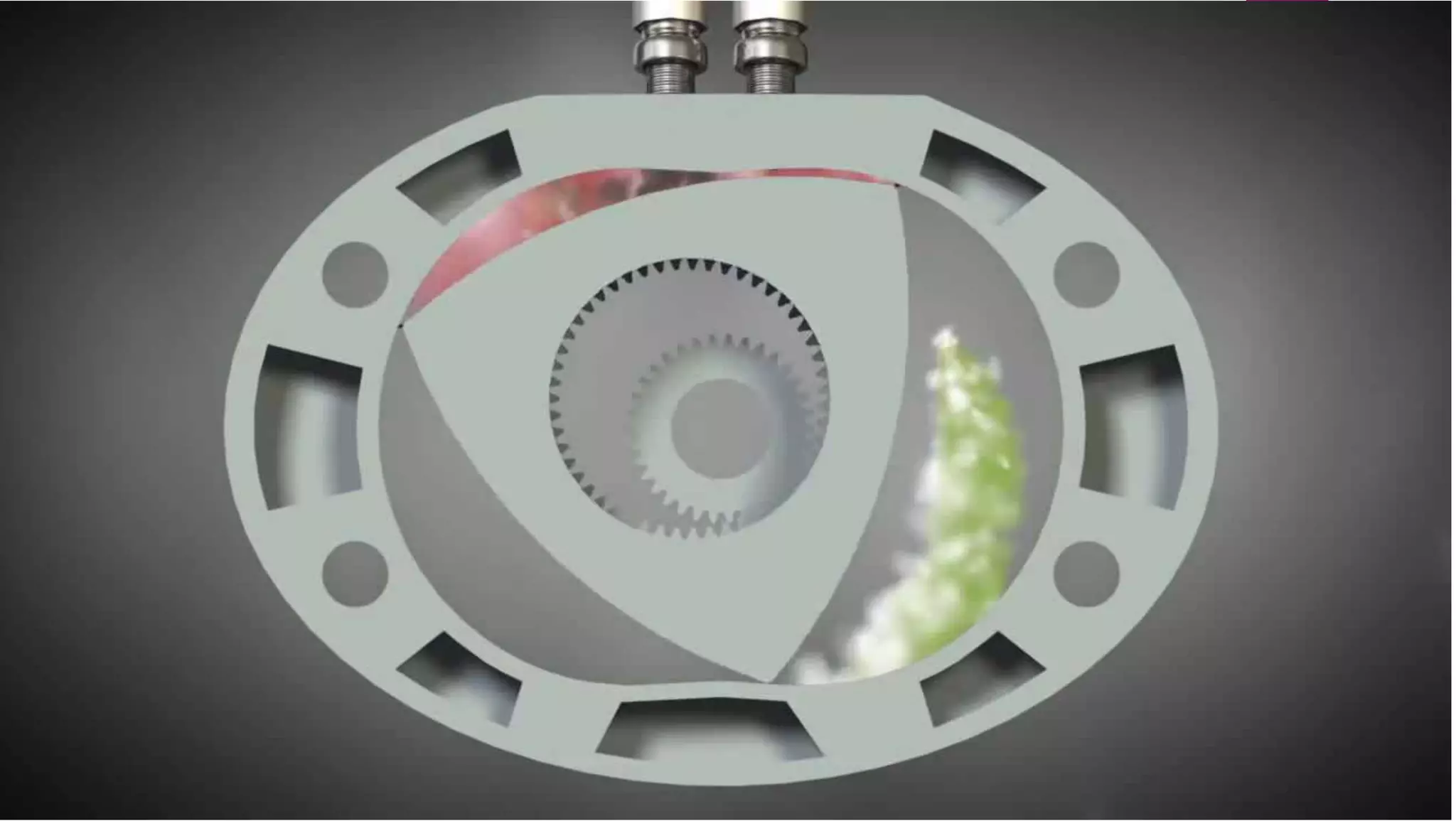

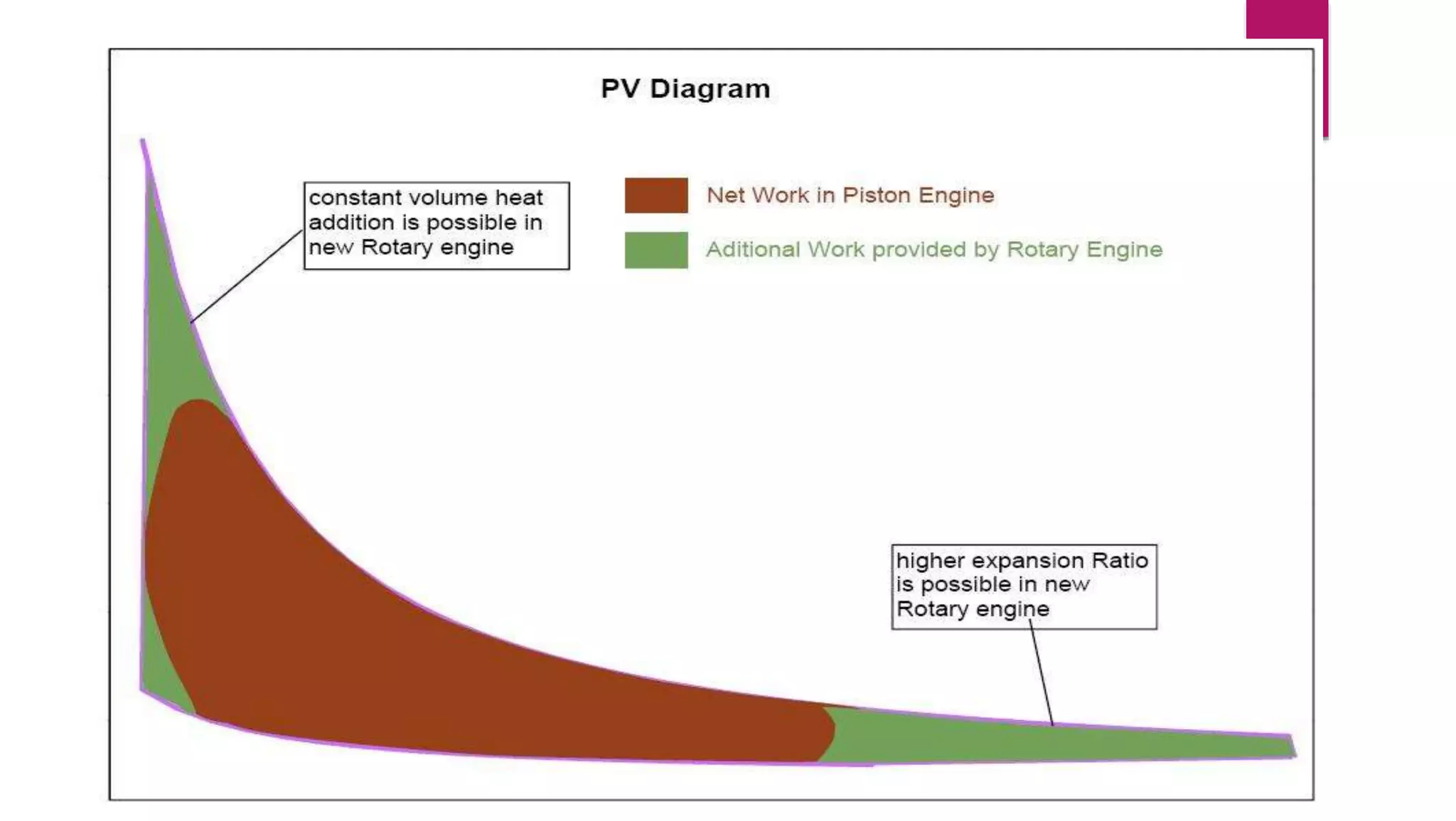

The Wankel engine uses an eccentric rotary design where the four strokes of a piston engine occur in the space between a three-sided rotor and a housing, rather than using pistons. It delivers advantages like simplicity, compactness, and high power-to-weight ratio over piston engines. Early prototypes were developed in the 1950s, and companies have since licensed the design and improved it. While it has better power density than pistons, Wankel engines face challenges with sealing and emissions that have limited their widespread adoption.