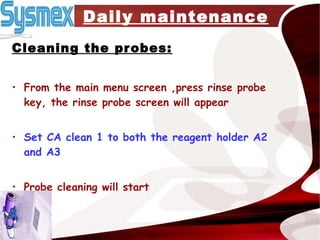

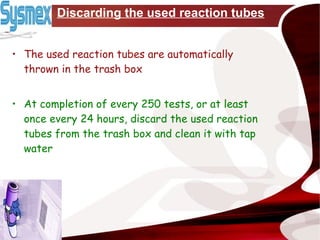

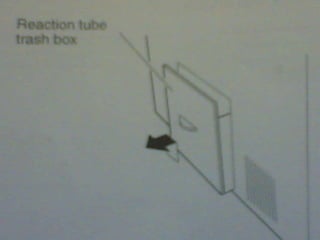

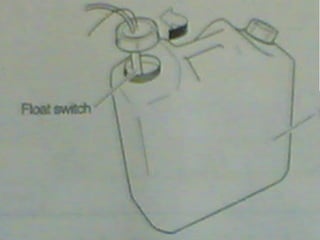

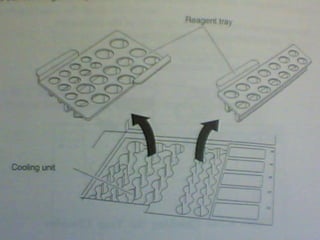

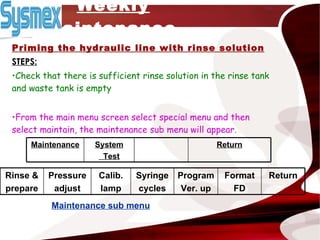

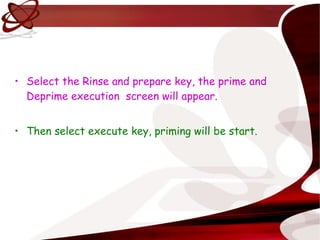

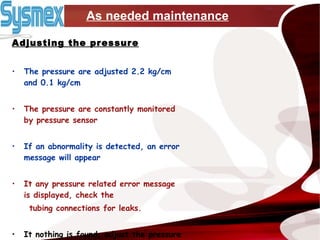

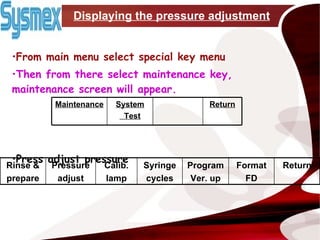

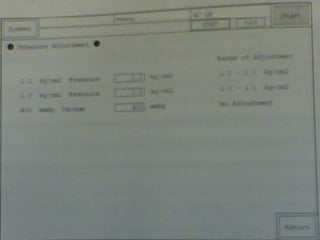

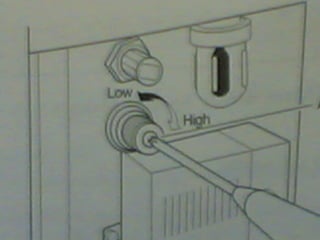

The document provides information about maintaining the Sysmex CA-1500 blood coagulation analyzer. It discusses the daily, weekly, and as-needed maintenance tasks required to keep the instrument in optimal operating condition. Daily maintenance includes cleaning probes, discarding used reaction tubes and waste, and running controls. Weekly maintenance consists of priming the hydraulic line and cleaning the instrument. Pressure adjustments are an example of as-needed maintenance. Proper maintenance is necessary to ensure the analyzer operates accurately and reliably.