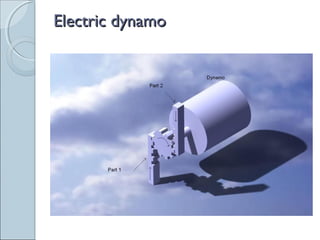

This document proposes generating electricity from speed breakers. It discusses using the kinetic energy from vehicles passing over speed bumps to power an electric generator via various mechanisms. The scope is to produce low-cost electricity at locations with traffic. Construction details and the basic principle of converting mechanical to electrical energy are provided. Challenges in initial experiments and achieving proper balance are also noted. While output was low, the concept was demonstrated. Future scopes include designs for heavier vehicles and more efficient mechanisms.