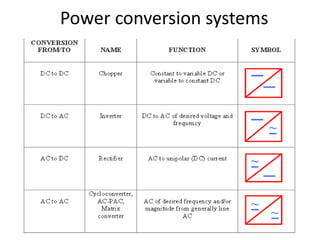

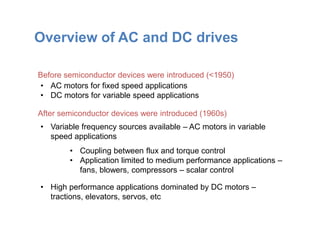

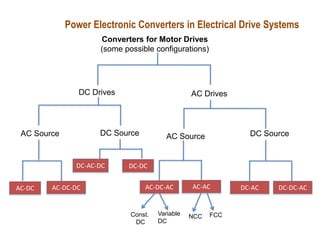

Power electronics deals with controlling and converting electric power through solid-state devices. It is used to improve efficiency in applications like motor drives, renewable energy systems, power transmission and distribution. Power electronics converters allow flexible control of AC motors for variable speed drives. Major applications include industrial motor drives, electric vehicles, renewable energy, and power supplies. Power electronics improves efficiency in energy conversion and transmission, enables control of electric power, and supports increasing use of renewable energy.