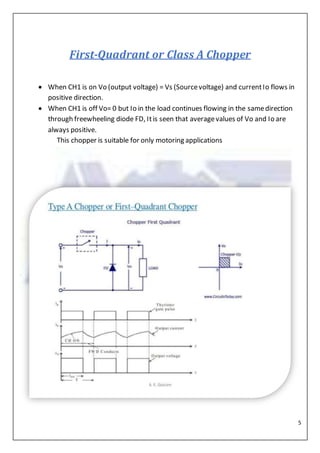

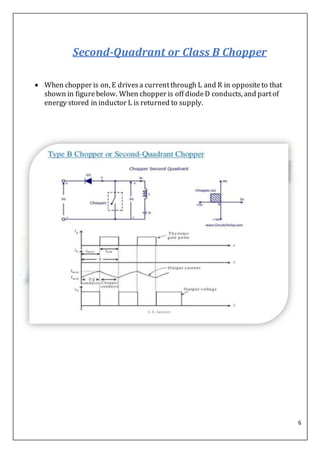

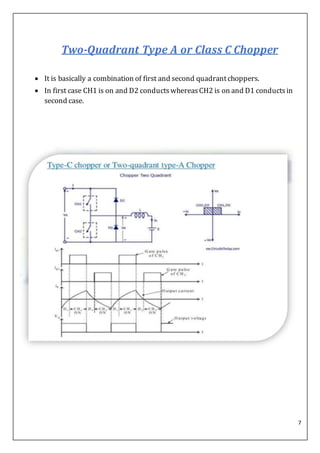

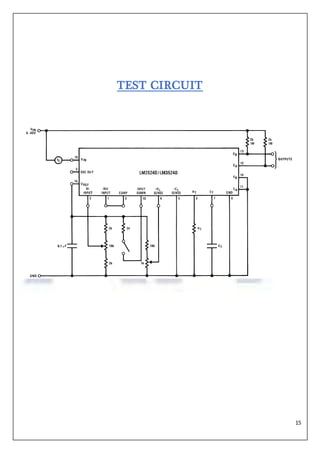

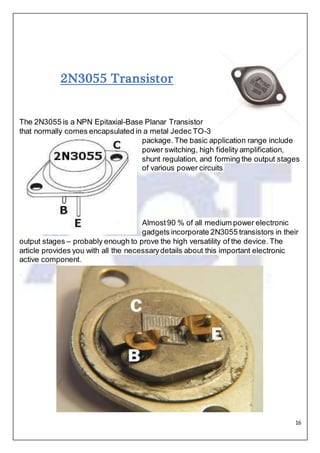

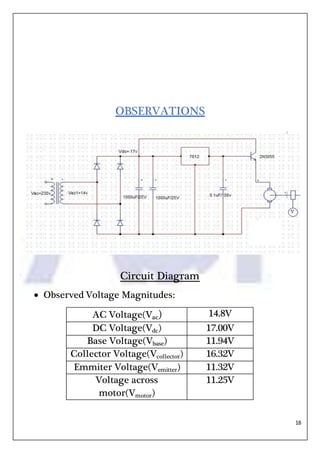

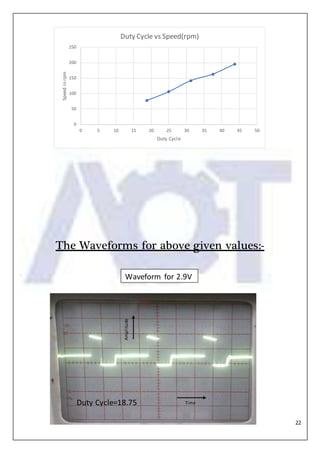

This document describes the design and performance study of a two-quadrant chopper drive. It begins with an introduction to choppers and their classification. It then discusses the different types of choppers - first quadrant, second quadrant, two-quadrant types A and B. It outlines the operations carried out by choppers and the components used in the model. Observations from the test circuit are presented along with graphs. Advantages include the ability for forward motoring and braking. Applications include electric vehicles and traction motor control. The conclusion is that regenerative braking is possible using a two-quadrant chopper.