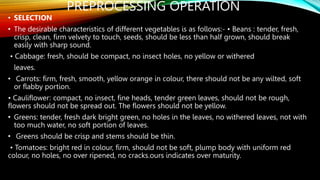

Vegetable processing involves the transformation of fresh vegetables into various forms for consumption, including beverages, dried, or pickled products. Key operations such as selection, cleaning, peeling, and cooling are emphasized to extend shelf life, maintain quality, and enhance market availability. Techniques like coating and modified atmosphere packaging are also utilized to protect produce from spoilage and preserve freshness.