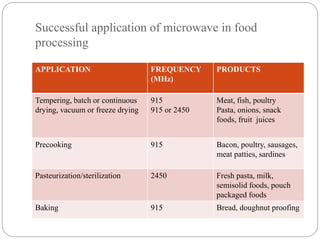

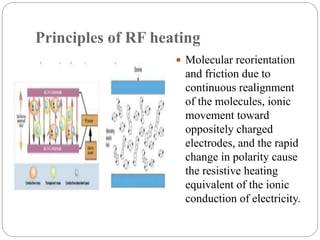

Microwave and radiofrequency processing are emerging food processing technologies. Microwaves have a frequency range of 300 MHz to 300 GHz and are used for applications like drying, cooking, and pasteurization. A microwave oven generates microwaves using a magnetron and consists of components like a waveguide and cooking cavity. Microwaves heat food through dielectric and ionic mechanisms. Radiofrequency uses frequencies from 1-300 MHz for applications such as blanching and dehydration. It induces volumetric heating through molecular reorientation and has higher penetration than microwaves. Both technologies provide advantages like faster and more uniform heating compared to conventional methods.