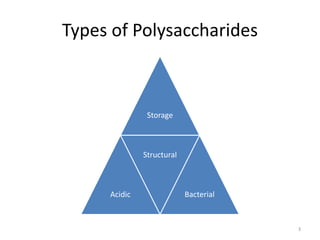

This document focuses on polysaccharides, specifically xanthan gum, detailing their structures, classifications, and properties. It describes storage, structural, and acidic polysaccharides, alongside the role of bacterial capsular polysaccharides. Additionally, it covers the production, fermentation conditions, and unique rheological properties of xanthan gum.