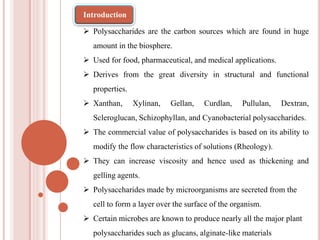

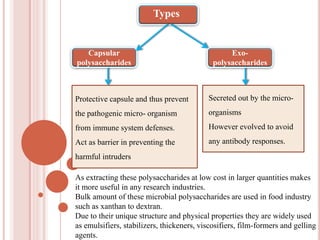

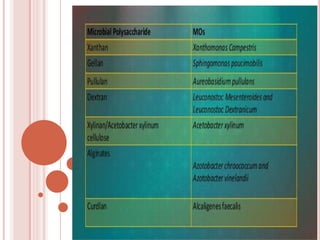

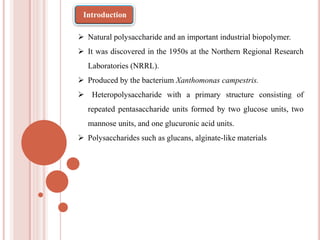

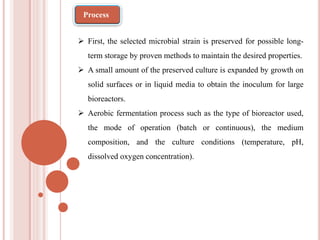

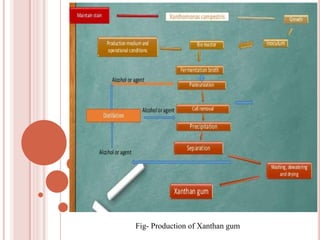

The document discusses microbial polysaccharides, focusing on production methods, particularly of xanthan gum, and their various applications in food and pharmaceuticals. It outlines the fermentation processes, recovery techniques, and the commercial significance of different polysaccharides including xanthan, gellan, pullulan, and dextran. These polysaccharides are noted for their properties as thickening, gelling, and stabilizing agents in various food products.