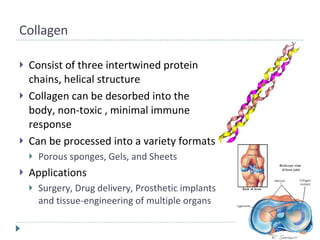

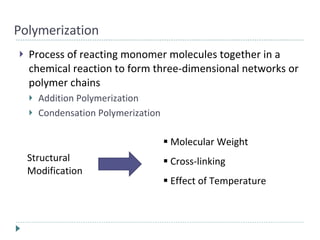

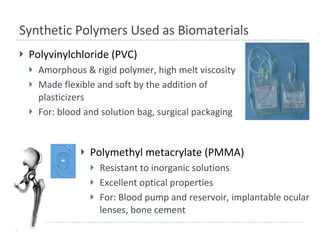

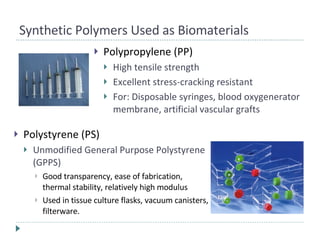

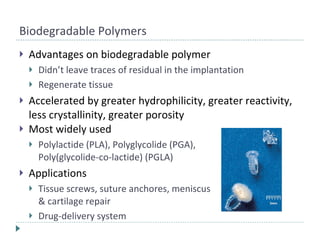

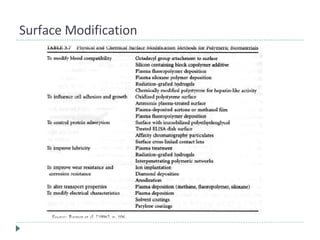

The document discusses polymeric biomaterials, including both natural and synthetic polymers. It describes commonly used natural polymers like collagen, chitosan, and alginate, which are biodegradable and can be processed into various formats. Synthetic polymers discussed include PVC, PMMA, PP, and PS. These have advantages of manufacturability but must be biocompatible. The document also covers polymerization processes and structural modification, as well as using surface modification like atomic oxygen treatment to increase hydrophilicity of polymers like polystyrene.

![감사합니다 Thank you for your attention…. - Questions & Discussion - [back to index of contents] mail to: ikhwan4ever@gmail.com](https://image.slidesharecdn.com/polymeric-biomaterials-1211006372434873-8/85/Polymeric-Biomaterials-by-15-320.jpg)