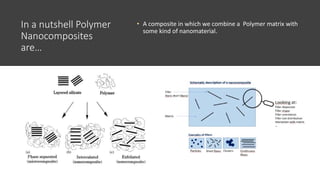

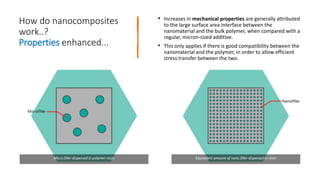

Polymer nanocomposites are materials that combine a polymer matrix with nanomaterials like nanoparticles, nanotubes, or nanoplatelets to enhance properties such as strength and conductivity without significantly increasing weight. These enhancements stem from the high surface area and interaction between the nanomaterials and the polymer, which can improve mechanical, thermal, and electrical properties. The processing and integration of nanomaterials into the polymer matrix are crucial and can be achieved through methods like in-situ polymerization or blending.