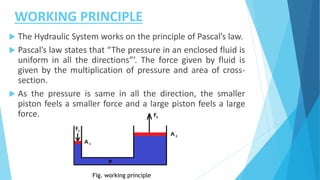

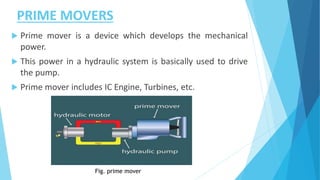

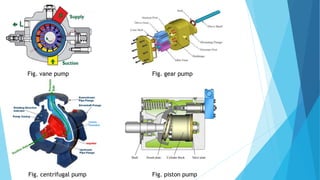

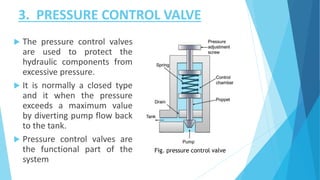

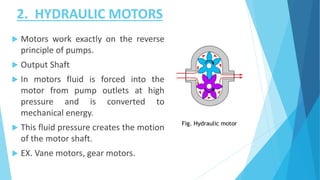

This document describes a hydraulic control system and its components. It discusses how hydraulic systems work using Pascal's law and fluid power. The key components of a hydraulic system are described as the prime mover, pump, control valves, actuators, fluid, filters and protective devices. Examples are provided of different types of pumps, control valves, actuators and applications of hydraulic systems in industries like manufacturing and construction.