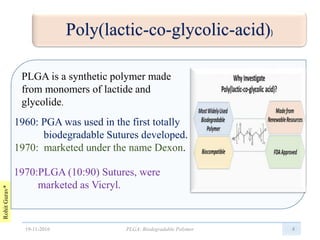

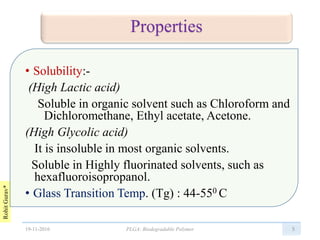

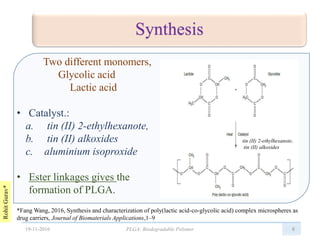

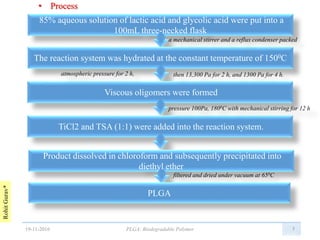

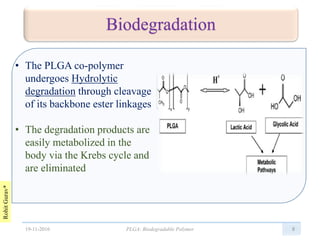

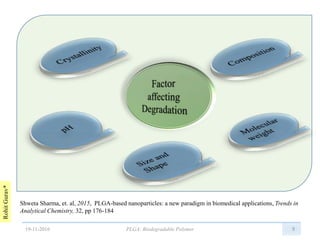

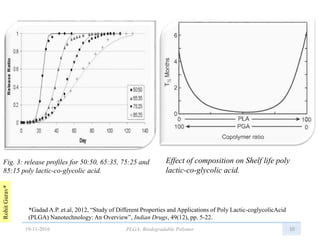

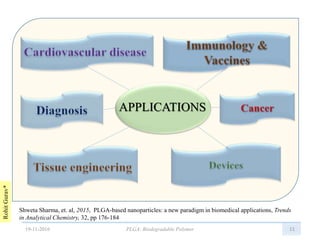

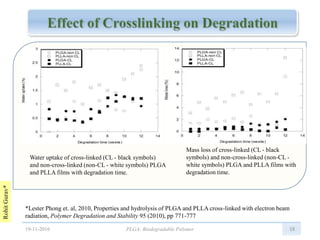

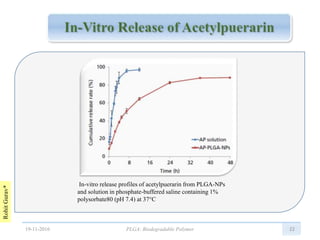

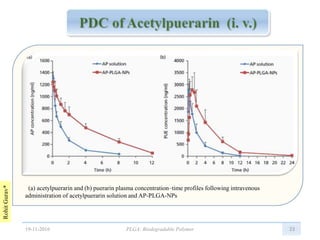

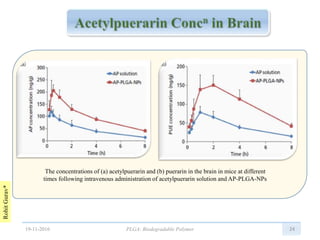

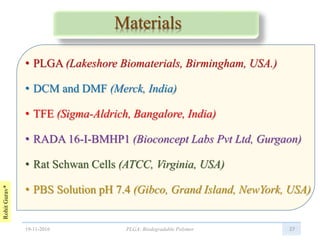

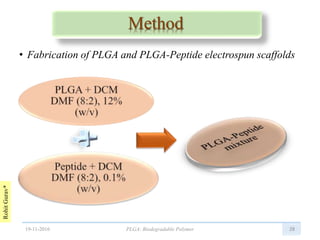

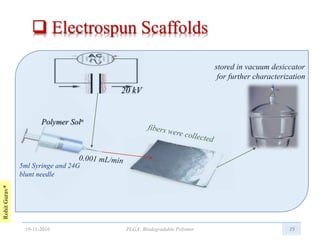

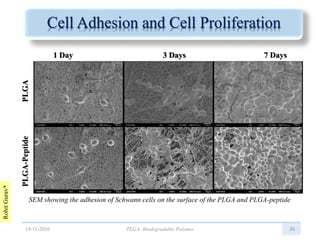

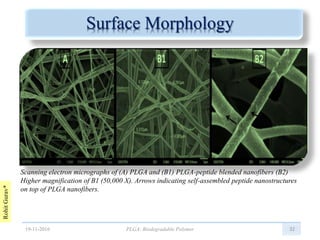

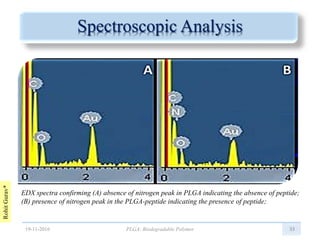

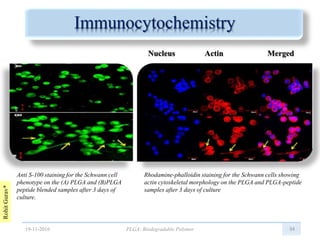

The document discusses poly(lactic-co-glycolic acid) (PLGA), a biodegradable polymer. It provides details on the synthesis of PLGA from lactide and glycolide monomers, its properties such as solubility and glass transition temperature, and its biodegradation process. Applications of PLGA include drug delivery systems, medical implants, and tissue engineering scaffolds. Case studies show that modifying PLGA with other polymers or peptides can improve drug permeability and distribution in tissues.