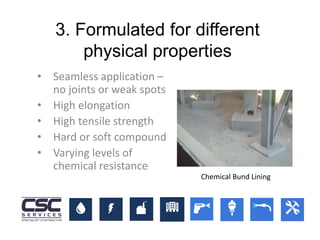

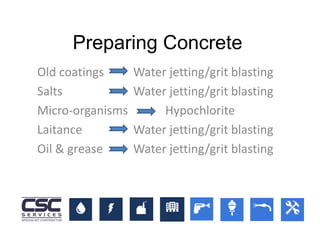

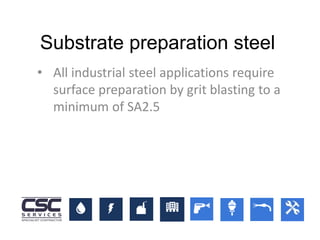

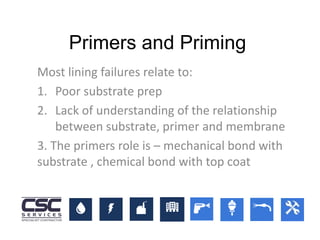

The document introduces a high-performance polyurea surface protection system by VIP Germany, suitable for various applications including wastewater treatment, oil and gas, military, and food manufacturing. It emphasizes the system's fast application, long life cycle, and resistance to chemicals, UV, and moisture, while detailing the importance of proper substrate preparation for effective application. CSC Services offers comprehensive support, including surface preparation, specialized coatings, and quality assurance practices.