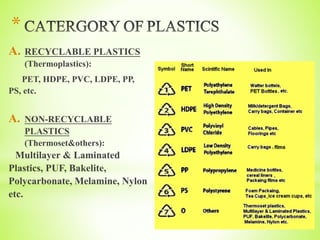

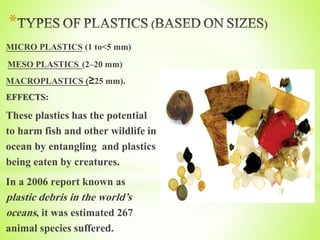

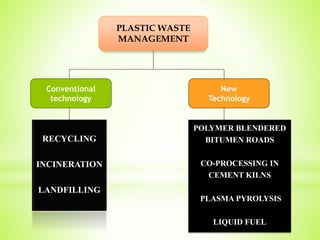

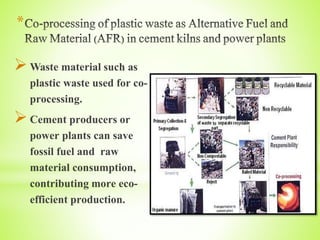

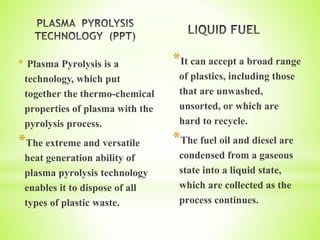

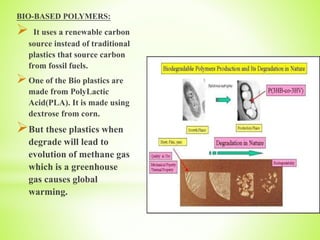

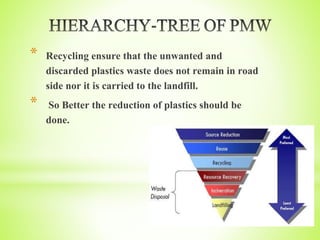

The document discusses the extensive use and contribution of plastics in various fields, highlighting their benefits such as durability and low cost, as well as the environmental concerns related to plastic waste and contamination in marine environments. It emphasizes the importance of effective waste management strategies, including recycling and new technologies like plasma pyrolysis, to address plastic pollution. Furthermore, the document calls for education and implementation of schemes to mitigate the impacts of plastic waste globally.