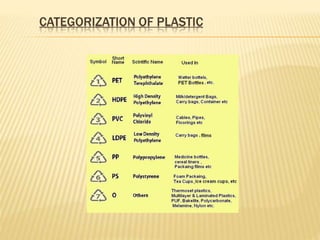

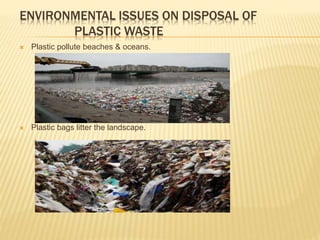

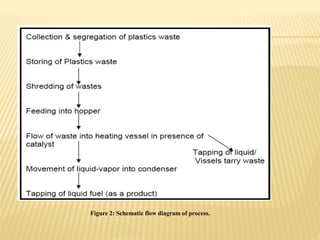

The document discusses the environmental challenges posed by plastic waste in India, highlighting the increase in plastic waste generation due to urbanization and industrial growth. It categorizes plastic materials, their disposal methods, and innovative technologies for waste management, including recycling and incineration. The conclusion emphasizes the need for effective strategies to mitigate plastic waste impacts while acknowledging ongoing challenges in collection and recycling efforts.