This document presents a student study project on plastic waste management methods. It was conducted by students in the Department of Chemistry at Government Degree College in Rangasaipet, Warangal, India under the supervision of an assistant professor. The project aims to learn about plastic, plastic waste, and eco-friendly plastic waste management methods. It analyzes three plastic waste management methods and provides explanations of key terms like plastic, plastic waste, and plastic waste management. It also discusses the issues caused by plastic pollution like groundwater, soil, and ocean pollution as well as dangers to human life.

![1. 6

Material Economics. (2018). The Circular Economy – a Powerful Force for Climate

Mitigation. Material Economics. https://materialeconomics.com/publications/the-circular-

economy-a-powerful-force-for-climate-mitigation-1 []

2. 7

Tangri, N. V. (2021). Waste Incinerators Undermine Clean Energy Goals. Earth

ArXiv. https://doi.org/10.31223/X5VK5X []

3. 8

The New School Tishman Environment and Design Center (2019). U.S. Solid Waste

Incinerators: An Industry in Decline. https://grist.org/wp-content/uploads/2020/07/1ad71-

cr_gaiareportfinal_05.21.pdf []

4. 9

Azoulay, D., Villa, P., Arellano, Y., Gordon, M. F., Moon, D., Miller, K. A., & Thompson,

K. (2019). Plastic & Health: The Hidden Costs of a Plastic Planet.

CIEL. https://www.ciel.org/reports/plastic-health-the-hidden-costs-of-a-plastic-planet-

february-2019/ []

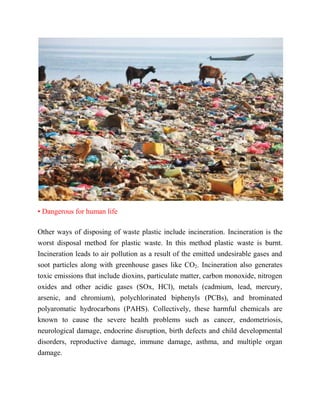

• Pollution in Oceans

Since the ocean is downstream from nearly every terrestrial location, it is the

receiving body for much of the plastic waste generated on land. Several million](https://image.slidesharecdn.com/jignasa-ii-230603095051-eab45210/85/Jignasa-II-docx-10-320.jpg)

![unincinerated) is stored in secure, contained landfills. Across such nations, almost no plastic waste is

regarded as partially managed. [3]

Across many low-to-middle-income income nations, insufficiently managed waste can be substantially

high; in fact, across many countries in South Asia and Sub-Saharan Africa, a staggering 80-90 per cent of

plastic waste is insufficiently managed, and consequently, holds a dangerous prospect of polluting

streams and oceans.

MANAGEMENT OF PLASTIC GARBAGE

Recycling, landfilling, and incineration are the most common traditional methods for

managing plastic garbage. However, because this plastic garbage is non-

biodegradable, it poses waste management issues. To safeguard the environment, the

most important issue is the effective and efficient management of the massive

volume of trash generated around the world. Sustainable plastic waste management is

a major issue that is attracting all environmental concerns.

RECYCLING OF PLASTICS

Recycling plastics entails repurposing the plastic product in its original or modified

form by depositing the waste streams in plastic recycling facilities(PRF). There are

four categories of plastic recycling technologies: primary, secondary, tertiary, and

quaternary.

In primary recycling, the waste stream is converted into a product with qualities

similar to the original product. Secondary recycling involves the processing of

garbage to produce goods with qualities that differ from those of the original product.

Plastic trash is treated in tertiary recycling to produce basic fuels and chemicals. The

energy content of waste plastics is retrieved in quaternary recycling by combustion or

incineration.

Selection of recyclable materials followed by the segregation of plastic waste are

effective methods of the recycling process. The segregated waste is then processed.](https://image.slidesharecdn.com/jignasa-ii-230603095051-eab45210/85/Jignasa-II-docx-13-320.jpg)