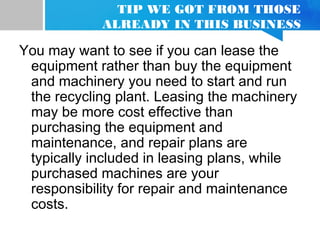

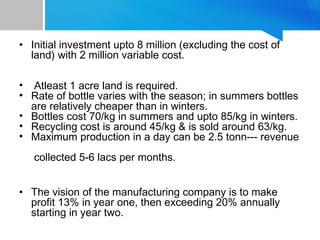

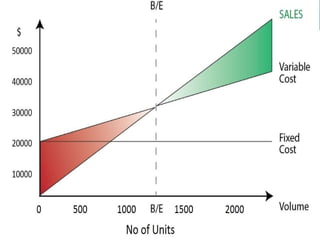

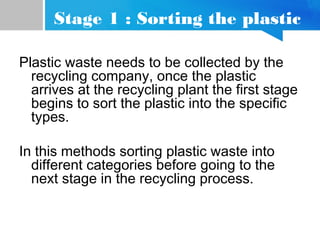

This document outlines a business plan for a plastics recycling business. It will require an initial investment of up to 8 million rupees excluding land costs, and will need at least 1 acre of land. The business will sort, wash, shred, and extrude plastic waste into new plastic rolls. It expects to process 2.5 tons of plastic per day, generating revenue of 5-6 lacs per month with profits increasing from 13% in the first year to over 20% annually going forward. Marketing will utilize traditional and digital methods. A tip suggests considering leasing rather than purchasing expensive equipment.

![]

Stage 5: Extruding

This is the final stage in

the recycling process

of plastic. This

process involves

melting clean

shredded plastic and

extruding into plastic

roll stock sheet.

This machine is quite

expensive so we'll

have it done from

local processors.](https://image.slidesharecdn.com/businessplan-180508063544/85/Plastic-Recycling-14-320.jpg)