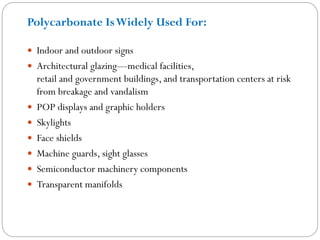

Plastic is a synthetic material made from organic polymers that can be molded into various shapes. There are two main types of plastics: thermoplastics and thermosetting plastics. Plastics have various advantages such as being lightweight, corrosion resistant, and inexpensive to produce. However, they also have disadvantages like being non-renewable, potentially causing cancer, and producing toxic fumes when burned. Polyvinyl chloride (PVC) is a versatile, cost-efficient thermoplastic with good properties for packaging and labeling. Polycarbonate is a tough, transparent plastic used for various applications because of its strength, optical clarity, and impact resistance. Fiber-reinforced plastics combine polymers with strong fibers and are