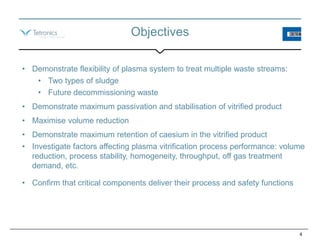

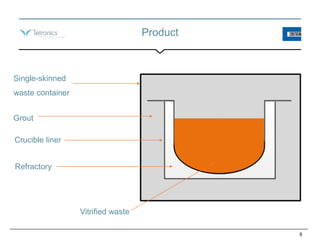

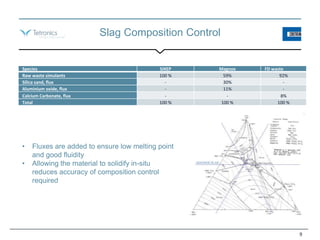

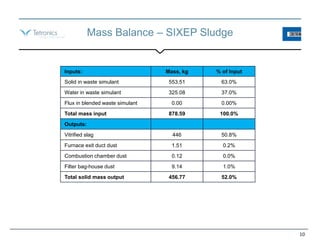

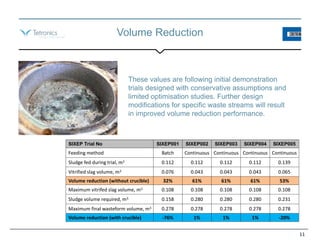

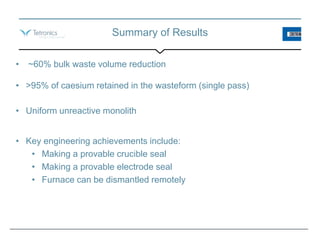

The document outlines the objectives and outcomes of a plasma waste vitrification process aimed at treating multiple types of nuclear waste, focusing on volume reduction and retention of caesium. It describes the design features of a demonstration plant and summarizes trial results indicating significant bulk volume reduction and high caesium retention rates. Next steps include pursuing funding for full-scale implementation and further development of the associated business case.