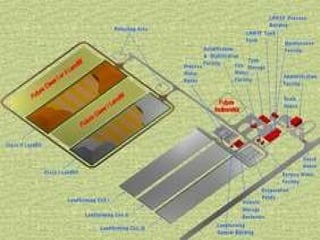

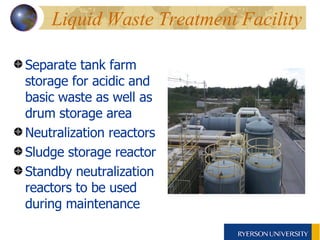

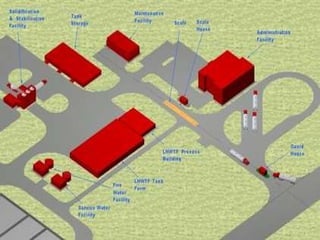

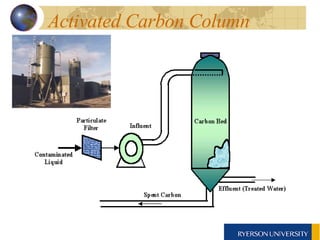

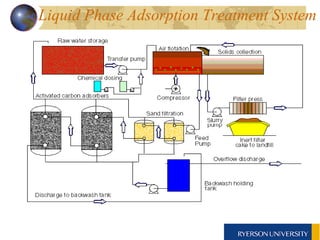

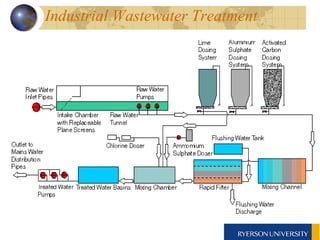

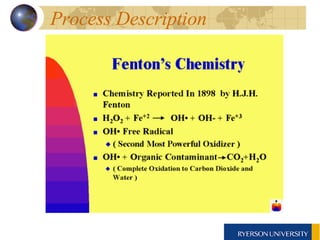

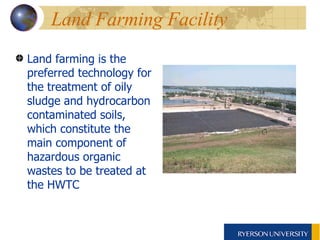

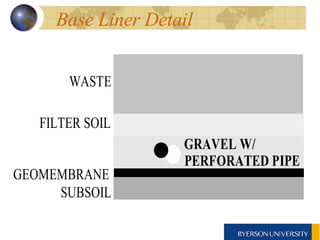

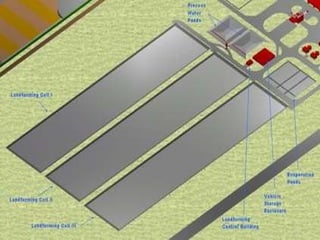

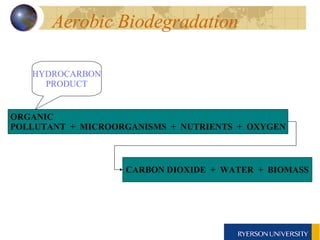

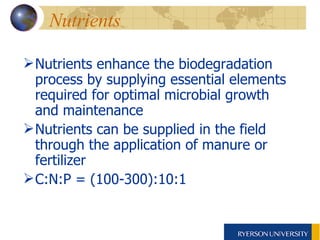

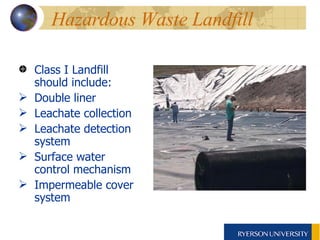

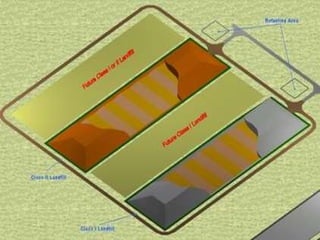

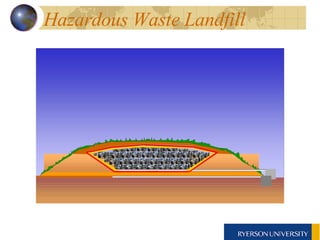

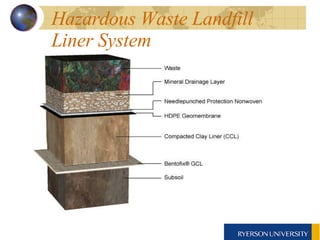

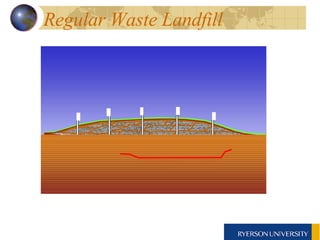

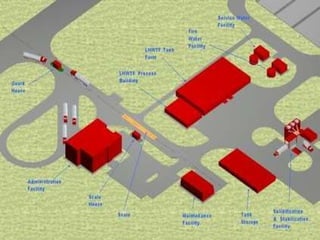

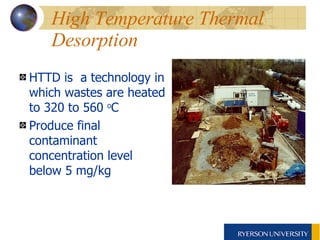

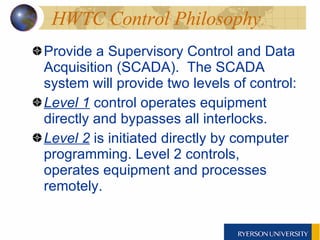

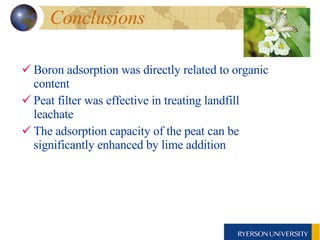

The document discusses hazardous waste management and the design of a Hazardous Waste Treatment Center (HWTC). The HWTC would include facilities for liquid waste treatment, land farming, hazardous and regular waste landfilling, solidification and stabilization, and incineration. The design aims to safely manage hazardous wastes while minimizing environmental and health risks through a modular and flexible approach.