The document details the ozonation process for bottled drinking water, highlighting equipment such as ozone generators and oxygen concentrators essential for air purification and ozone production. It outlines the objectives of ozonation, including the removal of impurities and enhancement of water quality, along with specifications for air and oxygen quality. Additionally, it provides equipment selection, sizing calculations, and maintenance logging practices for efficient operation.

![- Ozonation – Associated Equipments

5

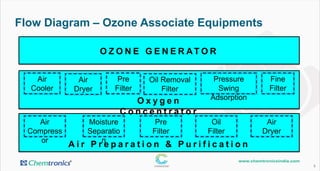

• Quality Of Ozone Depends Upon

»Quality & Technology of Ozone Generator

»Quality Of Feed Gas - Oxygen

• Quality Of Oxygen Depends Upon

»Quality & Technology of Oxygen Concentrator

»Quality Of Feed Gas – Air

• Quality Of Air Depends Upon

»Quality & Technology of Air Compressor

»Quality Of Air Purification [Pre-treatment]

Ozone Generator

Air Purification &

Oxygen Separation

Air Preparation &

Air Purification](https://image.slidesharecdn.com/ozoneinpackagebottleddrinkingwater-150912044027-lva1-app6891/85/Ozone-in-package-bottled-drinking-water-5-320.jpg)

![- Air Quality Specification - Requirements

10

• Dust [Solids] - < 5.0 Micron

• Oil - < 0.1 ppm

• Temperature - < 40°C

• Moisture - < 200 ppm

• Due Point - < - 15 ° C

• Pressure - 7.0 bar (min.)](https://image.slidesharecdn.com/ozoneinpackagebottleddrinkingwater-150912044027-lva1-app6891/85/Ozone-in-package-bottled-drinking-water-10-320.jpg)

![- Oxygen Concentrator

11

• Pre Filter + Oil Filter + Air Dryer – With Auto Drain

• Pressure Swing Adsorption [PSA] Oxygen Concentrator

• High Pressure Zeolite Molecular Sieves [ZMS] - - - 6 – 8 bar

• High Strength, Friction & Abrasive Resistant ZMS

• Longer Operation Life - - - - - - - - - 4 – 6 years

• Serge Tank for Stabilization & Purity

• PLC Bases Operation - Precise Timing Control

• Pneumatically Operating High Speed Solenoid](https://image.slidesharecdn.com/ozoneinpackagebottleddrinkingwater-150912044027-lva1-app6891/85/Ozone-in-package-bottled-drinking-water-11-320.jpg)

![- Oxygen Specification

13

• Concentration - 93 % ± 3 %

• Solids - < 0.02 Micron

• Moisture - < 80 ppm [0.1 ml / m³ of Oxygen]

• Oil Content - < 0.1 ppm

• Due Point - Standard – 40 °C ; - 60 °C [If Required]

• Oil Content - < 0.1 ppm

• Out Put Pressure - 40 psi (min.)](https://image.slidesharecdn.com/ozoneinpackagebottleddrinkingwater-150912044027-lva1-app6891/85/Ozone-in-package-bottled-drinking-water-13-320.jpg)

![- Ozone Generator - IV Generation

14

• Ozone Cell Cooling - Internally & Externally Water Cooled [Both Electrodes]

• Insulated Gate Bipolar Transistor [IGBT]

• Isolated Enclosures – Electronics : IP 54 ; Ozone Cell : IP 65

• Enclosure CE Marked & UL Certified

• Switch Mode Power Supply [SMPS]

• Soft Start & Soft Shut Off

• Ozone Cell Life – 20,000 Working Hours](https://image.slidesharecdn.com/ozoneinpackagebottleddrinkingwater-150912044027-lva1-app6891/85/Ozone-in-package-bottled-drinking-water-14-320.jpg)

![- Ozone Generator – Driver Circuit Protections

16

• Power Line – Surge & Spike Protection

• Over Voltage - Supply

• Under Voltage - Supply

• Over Heat [Temperature]

• Over Current – High Voltage

• Open Circuit – High Voltage

• Short Circuit – High Voltage](https://image.slidesharecdn.com/ozoneinpackagebottleddrinkingwater-150912044027-lva1-app6891/85/Ozone-in-package-bottled-drinking-water-16-320.jpg)

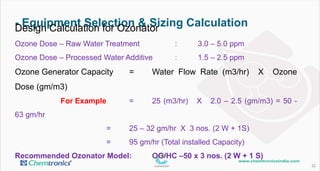

![- Equipment Selection & Sizing Calculation

23

Design Calculation for Oxygen Concentrator

•Feed Gas : Pure Oxygen Gas with following specification

•Purity : ≥ 92 %

•Oxygen Pressure : 1.0 – 1.4 bar

Required Oxygen

Quantity Ozone Concentration (gm/m3)

0.15 = 1.1 Nm3/hr i.e. 18 LPM

Total Ozone Capacity (gm/hr)

95 (gm/hr)

100 (gm/m3)

=

O2 Drying %

[16.0 %]+

+

=](https://image.slidesharecdn.com/ozoneinpackagebottleddrinkingwater-150912044027-lva1-app6891/85/Ozone-in-package-bottled-drinking-water-23-320.jpg)