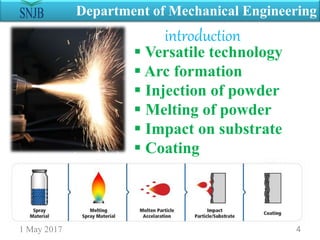

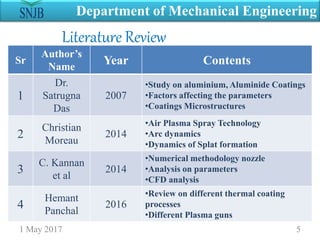

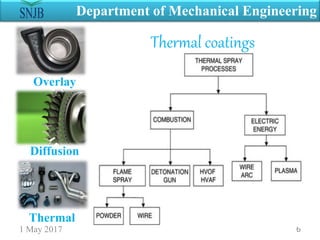

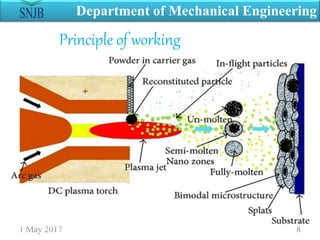

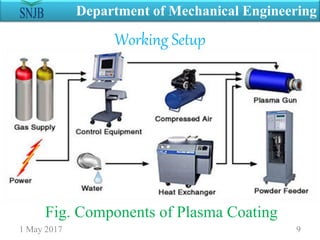

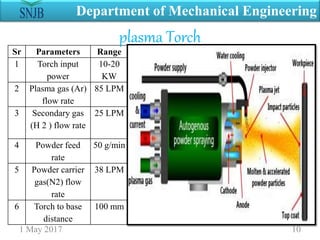

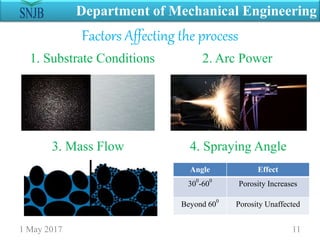

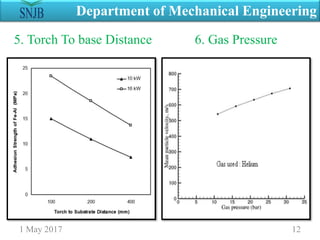

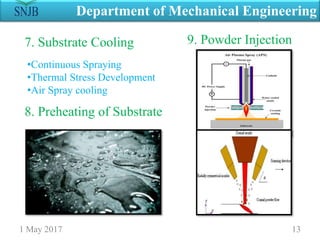

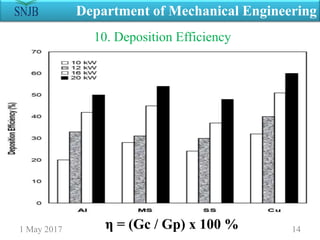

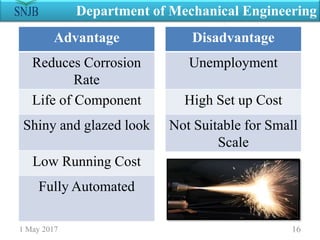

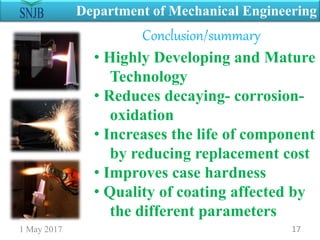

The document discusses plasma spraying technology, a method of surface engineering that enhances the durability of materials by applying thermal coatings. It outlines the principles of plasma generation, the working setup, key parameters affecting the process, and various applications of the technology. The conclusion highlights the technology's advantages, such as improved component life and reduced corrosion, while noting its high setup costs and unsuitability for small scale operations.