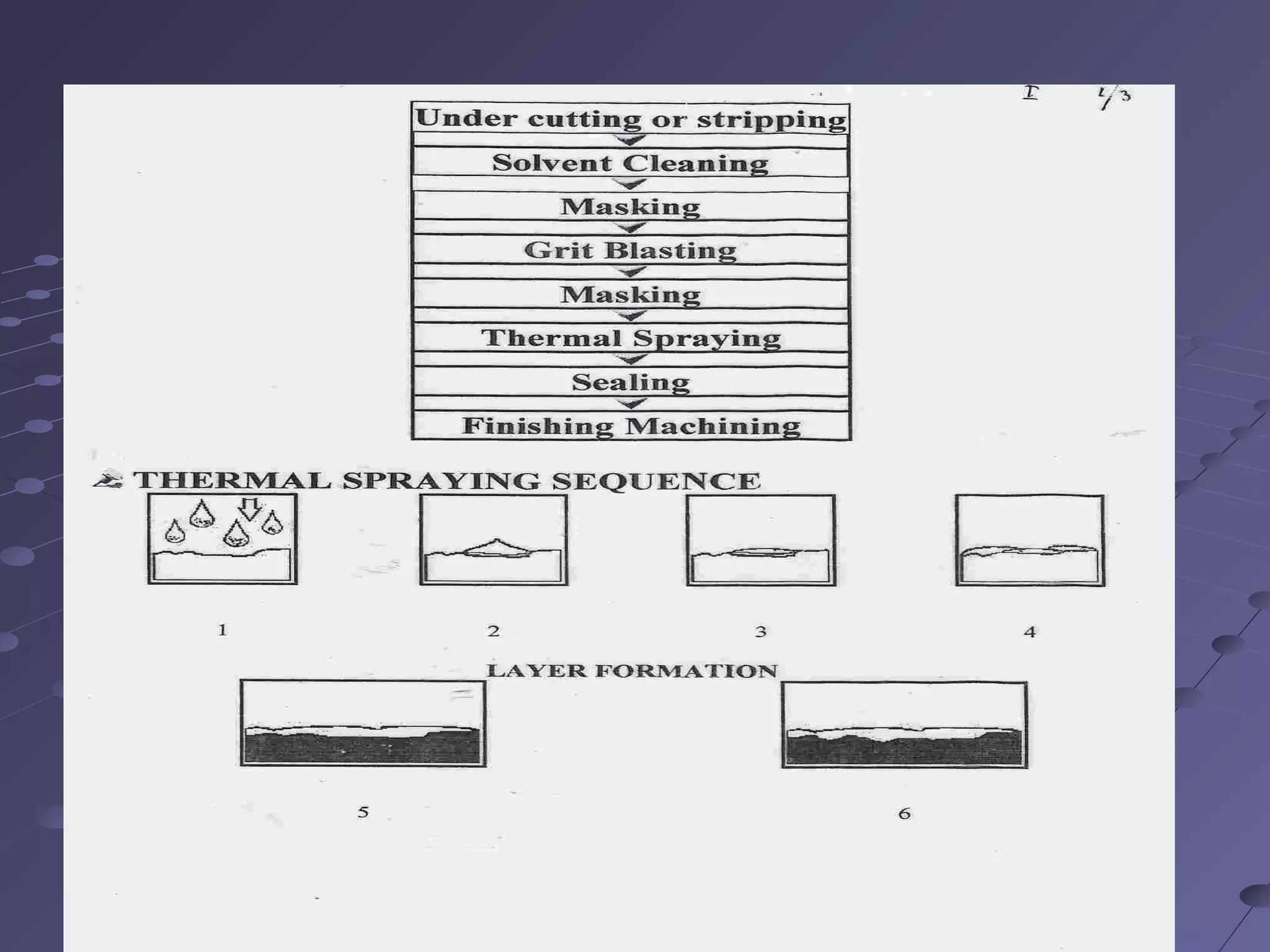

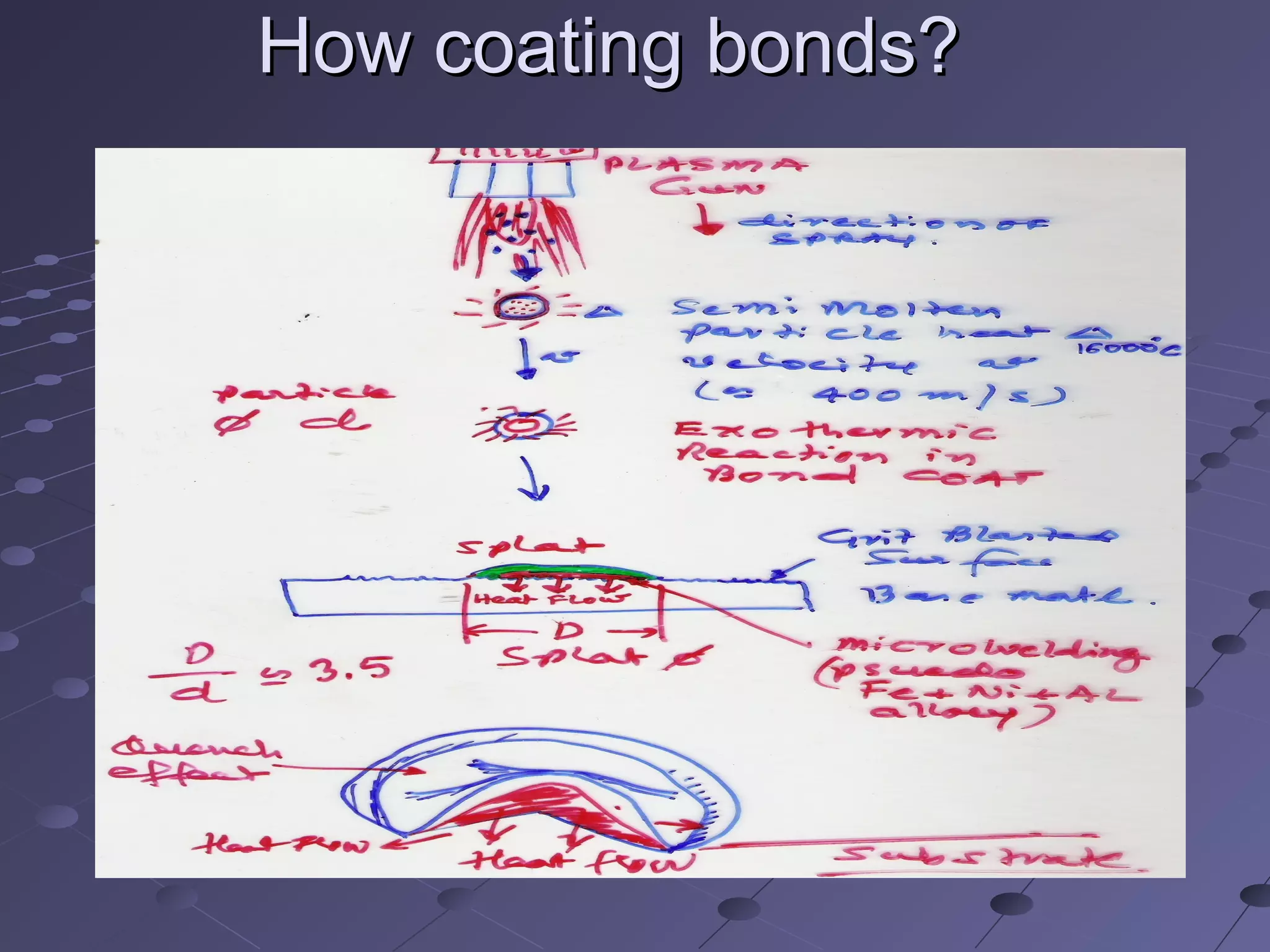

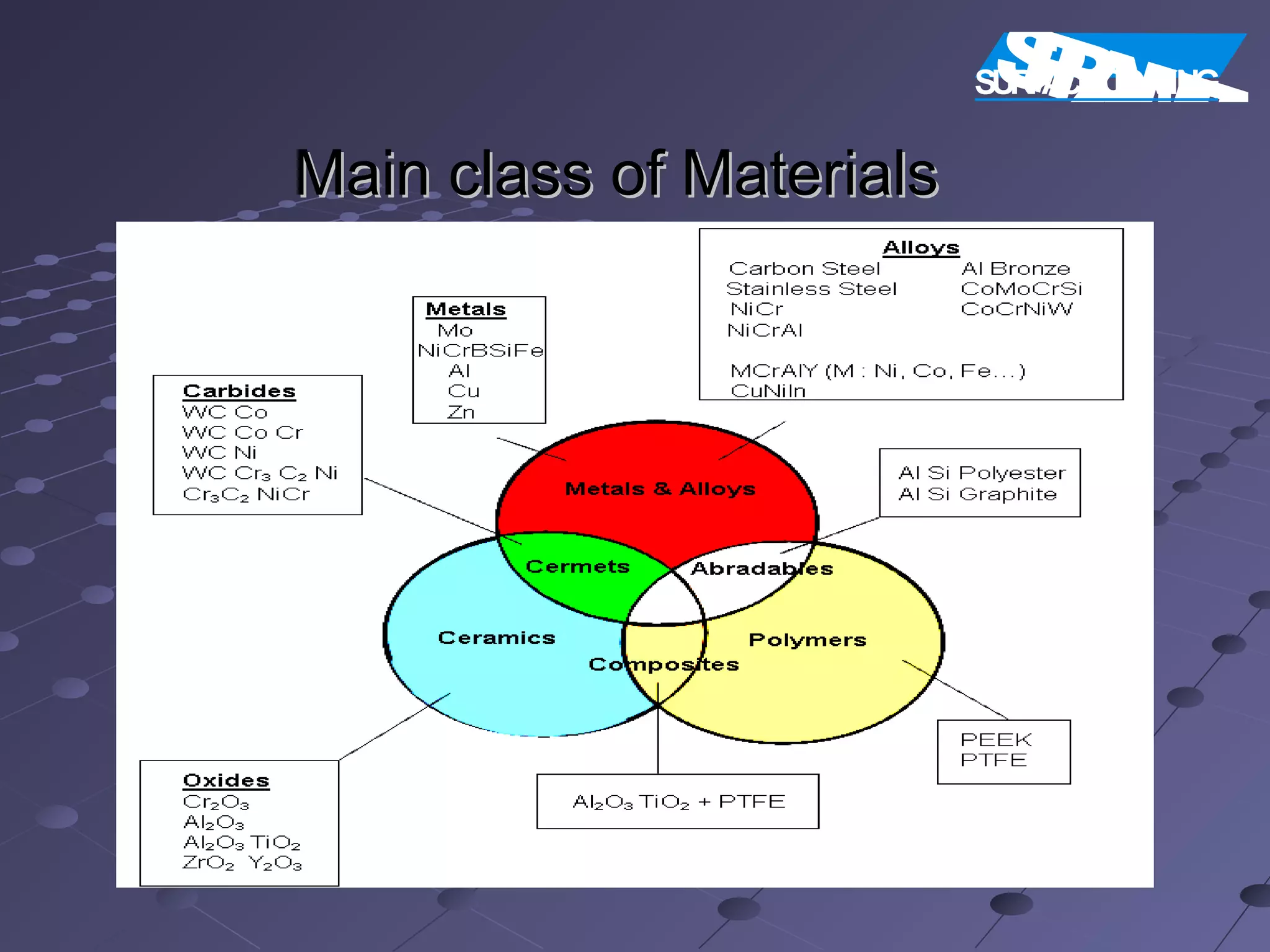

- Spraymet Surface Technologies provides thermal spray coatings and cladding services using techniques like HVOF and plasma spraying.

- They have facilities in Bangalore and Pune equipped with robotic sprayers, grinding, blasting and other processing equipment.

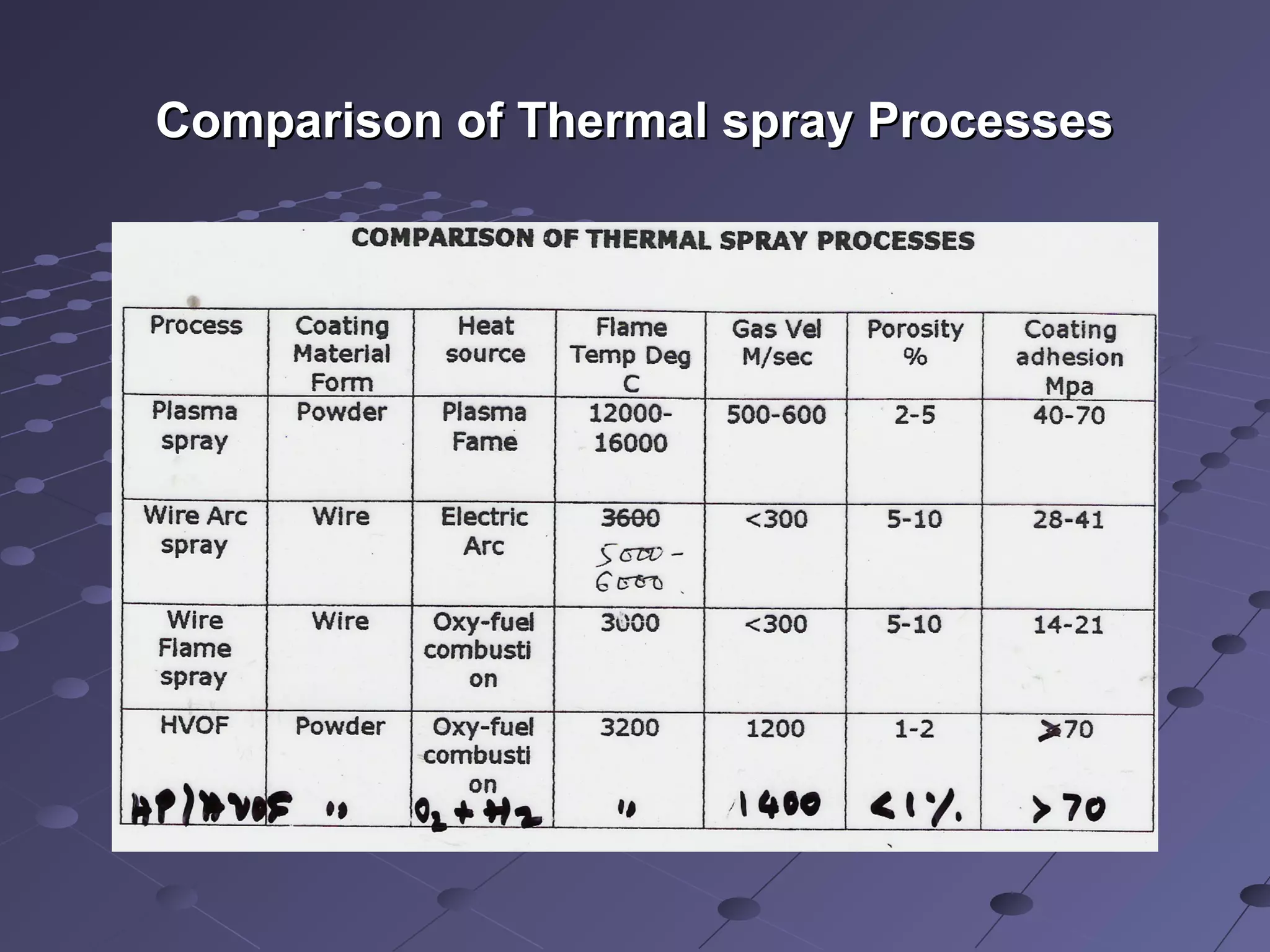

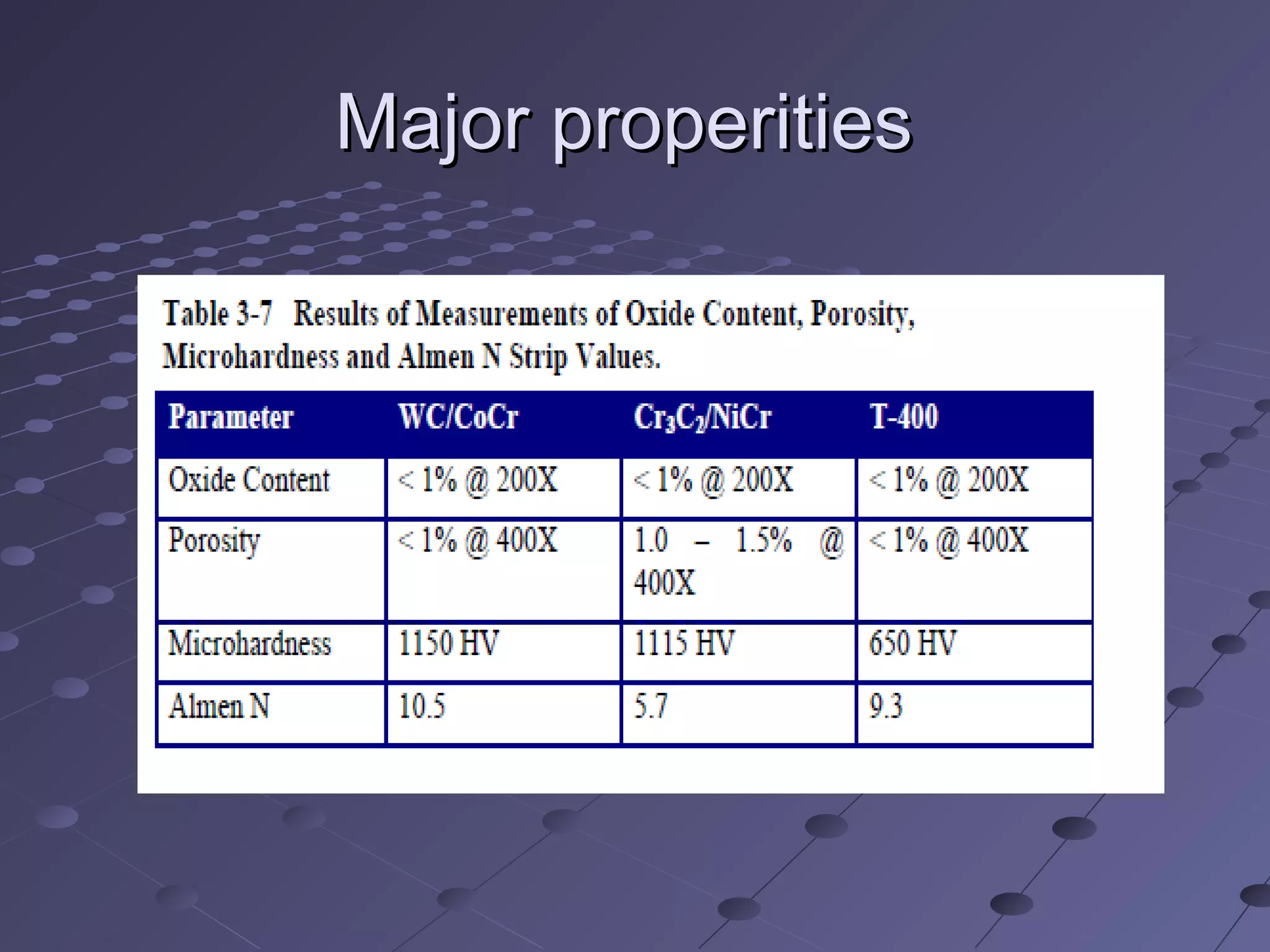

- Thermal spray coatings offer benefits over hard chrome plating like lower capital costs, selective application, and no hazardous waste generation. HVOF spraying in particular produces very dense coatings with high bond strength.

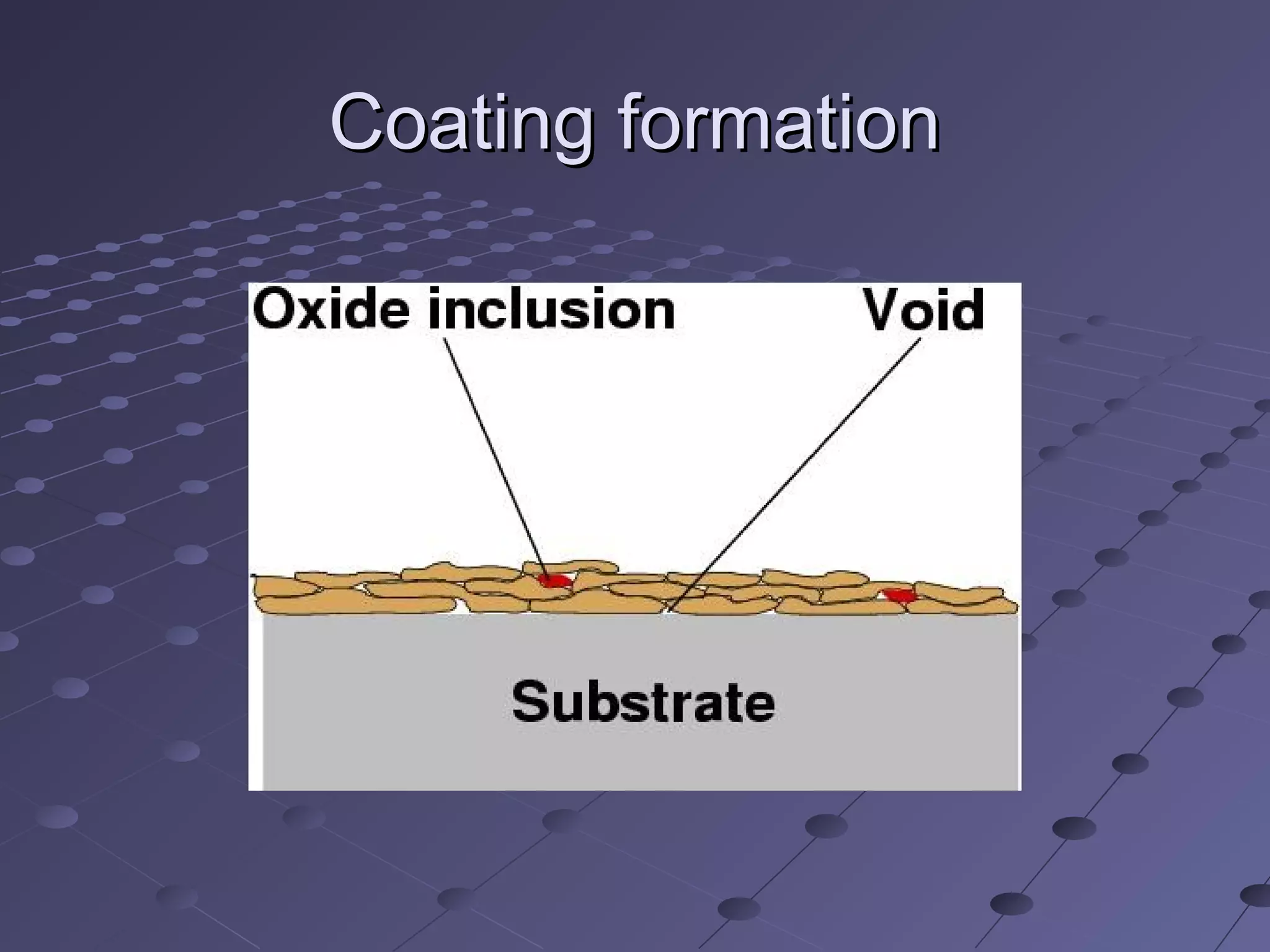

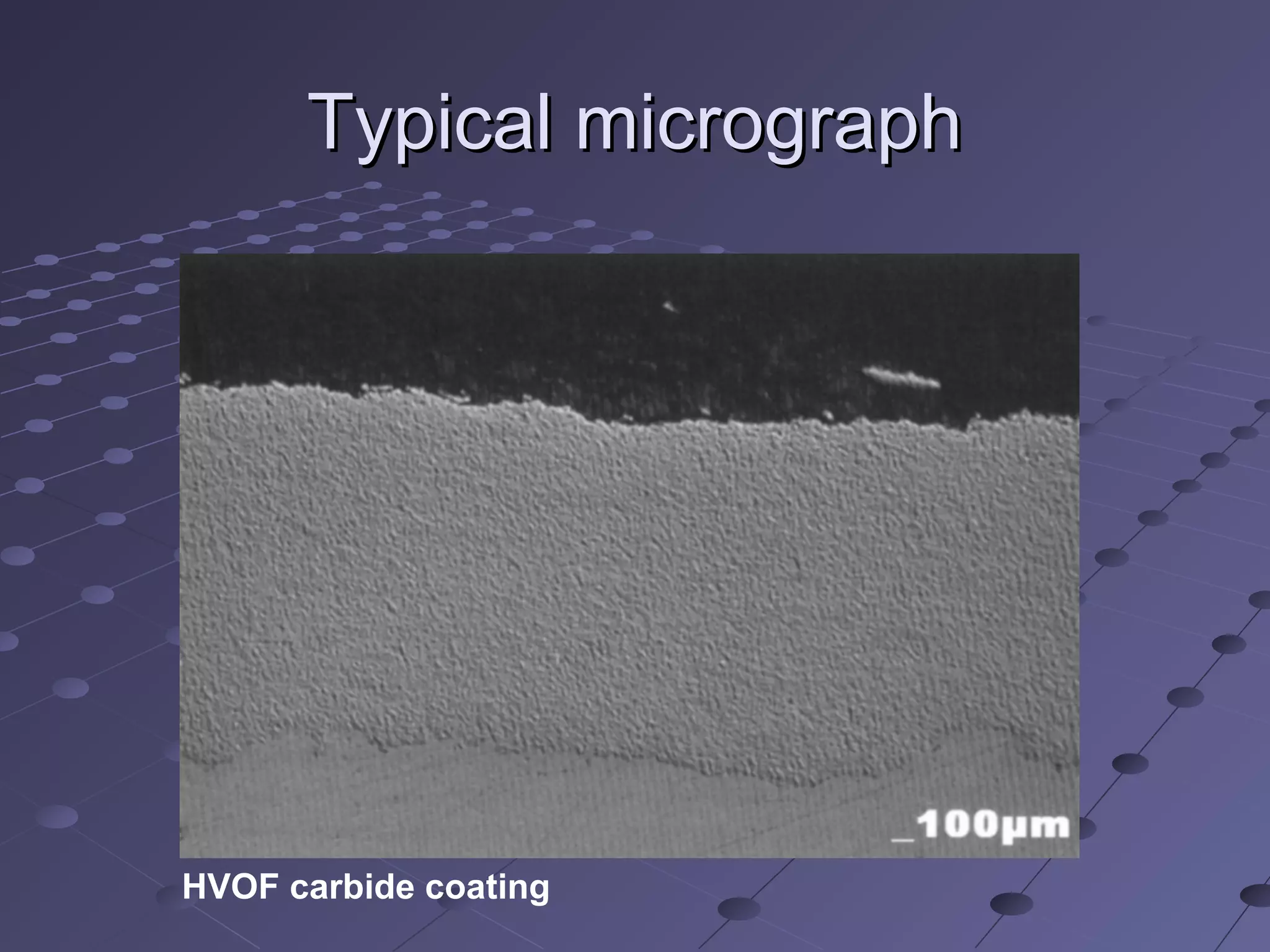

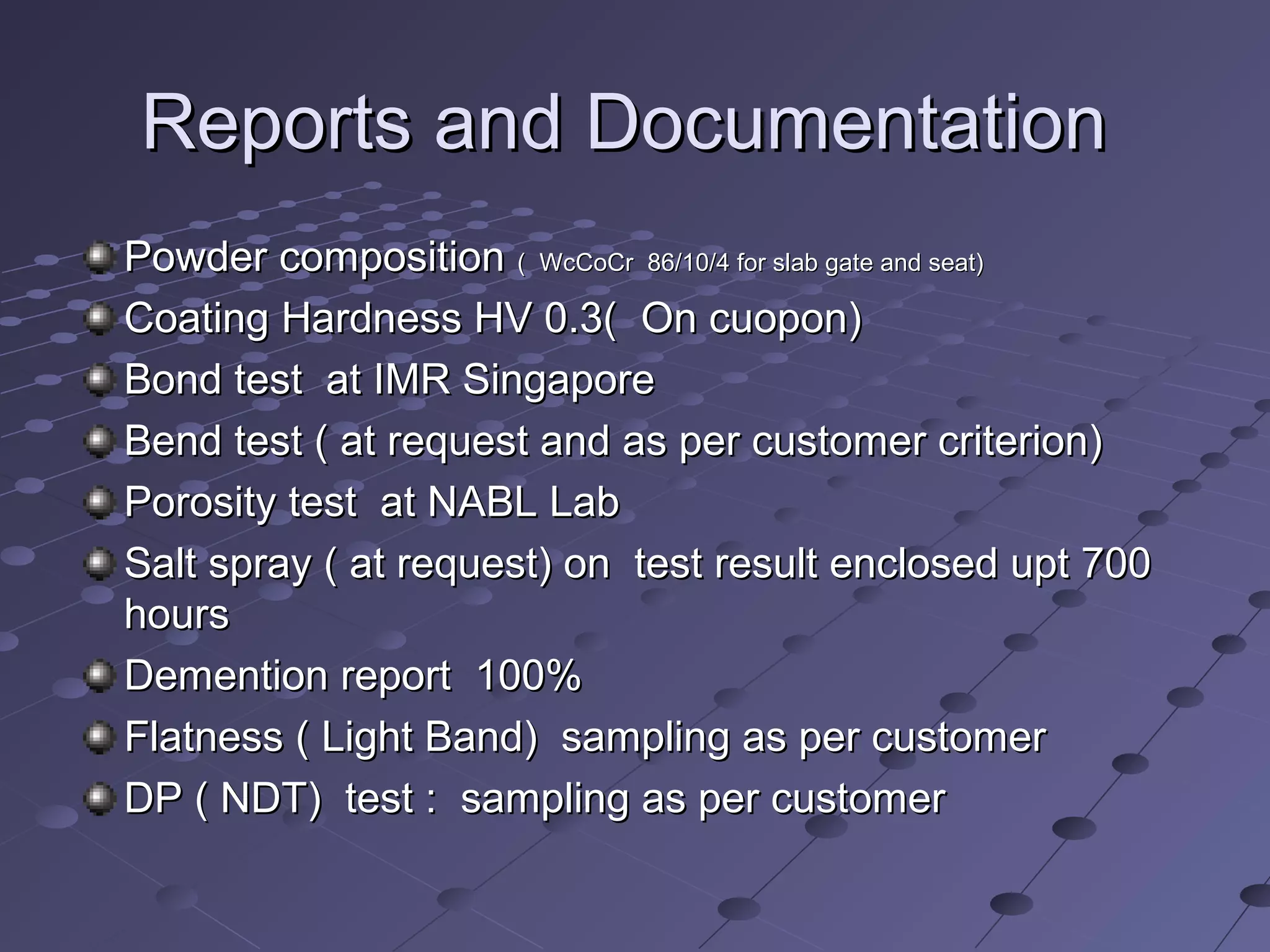

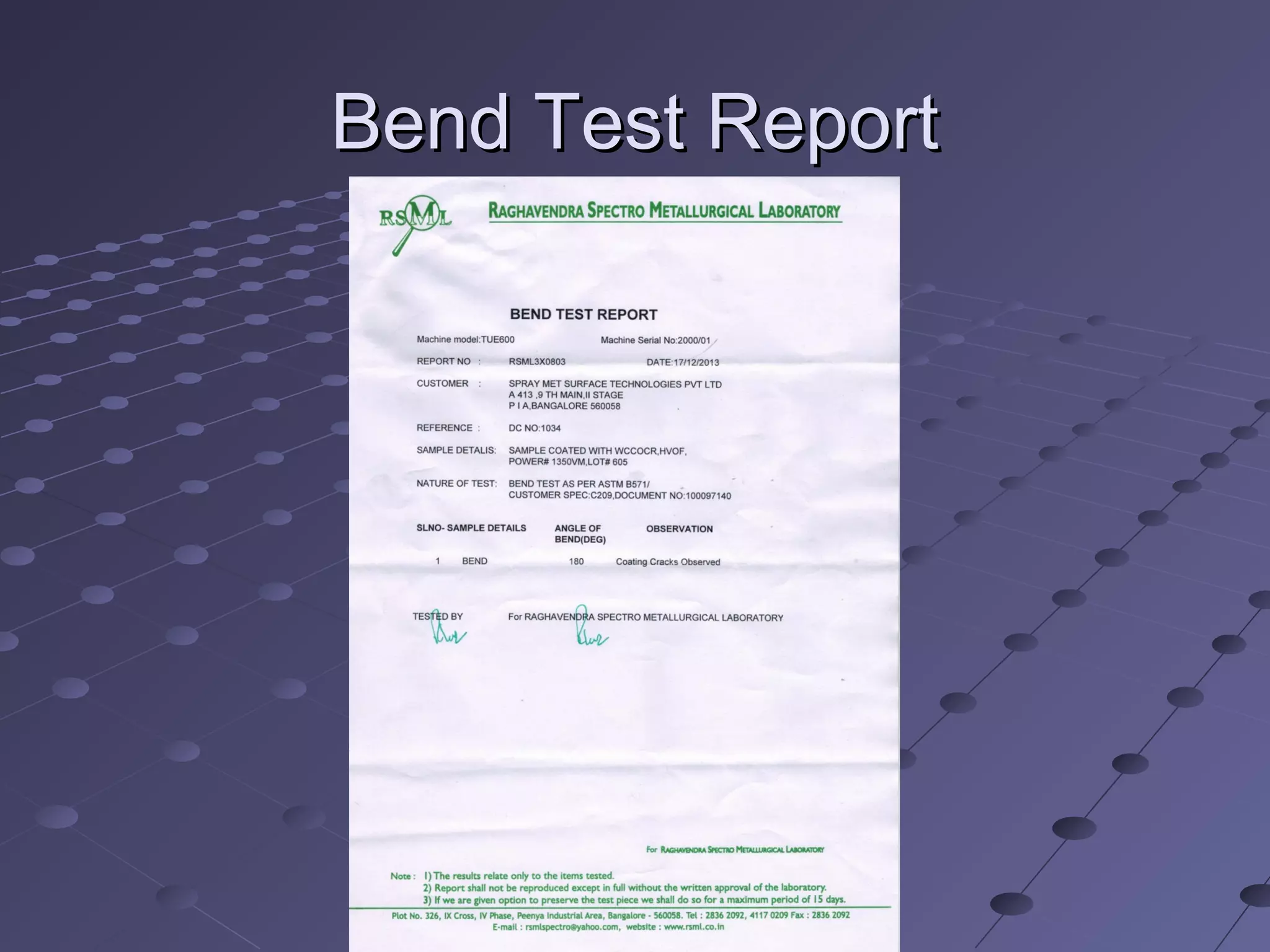

- Spraymet evaluates coatings for properties like hardness, porosity, bond strength and corrosion resistance to validate coating performance for applications in industries like automotive, steel, pumps, and oil & gas.