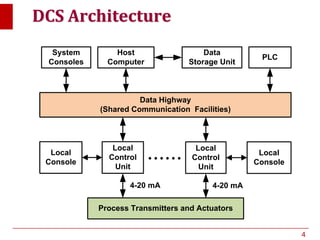

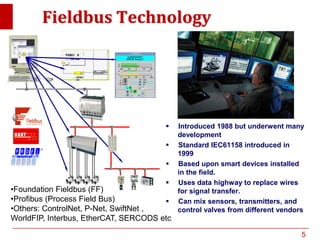

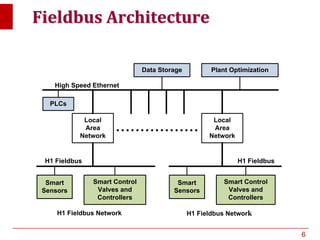

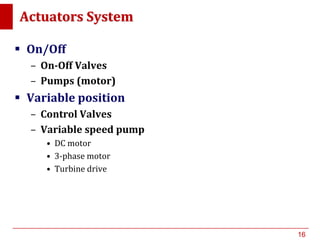

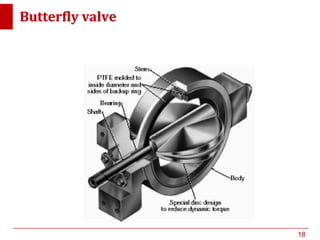

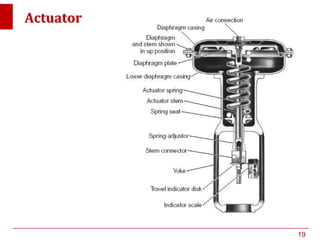

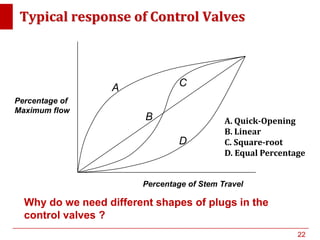

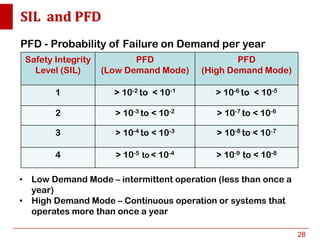

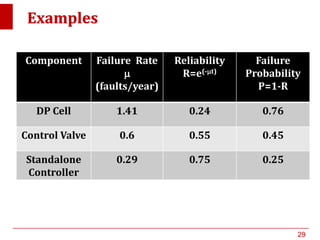

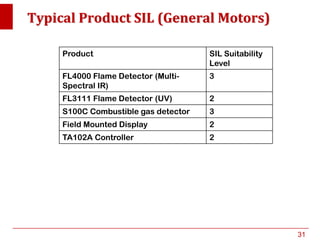

This document provides an overview of plant operation systems including distributed control systems (DCS), programmable logic controllers (PLC), and fieldbus technology. It discusses typical objectives of plant operation like protecting people, equipment, and the environment. It describes DCS architecture with components like transmitters, actuators, and control units connected via a data highway. Fieldbus technology is introduced to replace wires for signal transfer between smart field devices. The document also covers sensor systems for measuring variables like temperature, pressure, flow, and level. It discusses actuators, control valves, safety features, and reliability calculations. Safety integrity levels (SIL) are defined on a scale of 1 to 4 based on probability of failure on demand.