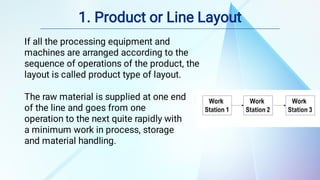

This document discusses plant layout, including the four main types: product or line layout, process or functional layout, fixed position layout, and combination layout. It describes each type and provides examples. Additionally, it covers the importance of plant layout in reducing costs, ensuring efficient production capacity and workflow, optimizing space utilization, and facilitating supervision. The objectives of a good plant layout are also outlined, such as minimizing delays and work-in-progress, utilizing space efficiently, providing flexibility, and ensuring safety.