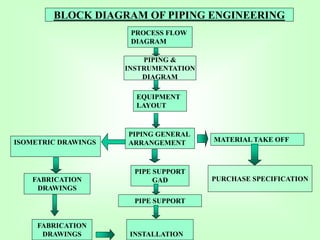

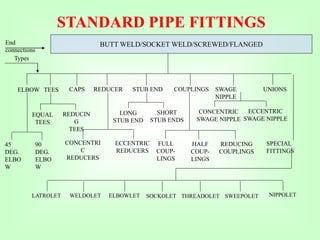

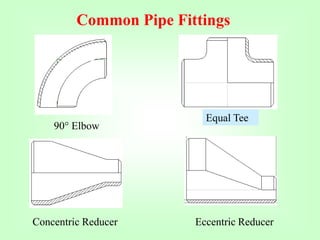

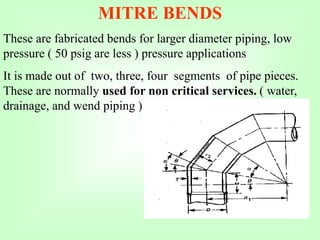

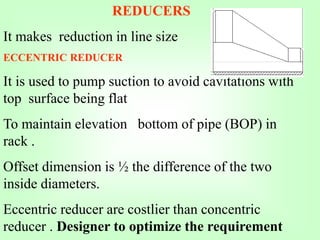

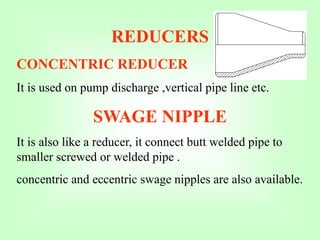

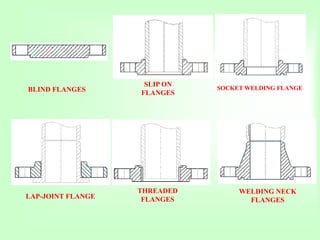

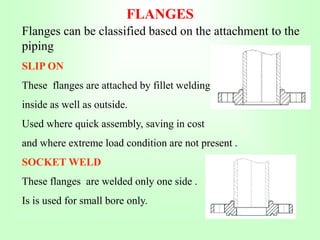

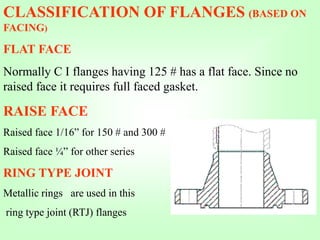

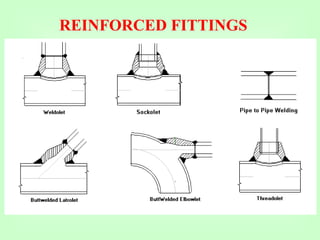

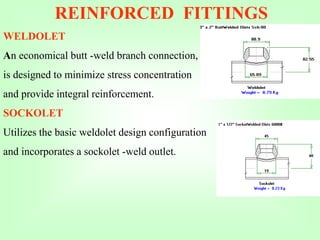

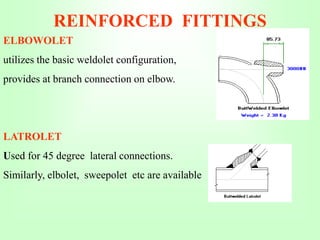

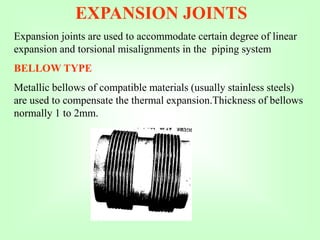

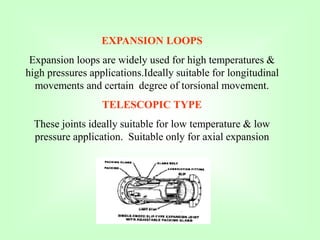

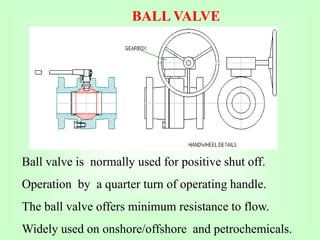

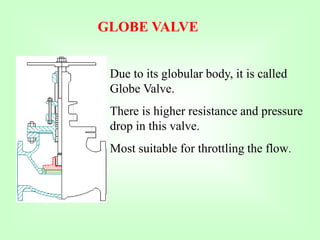

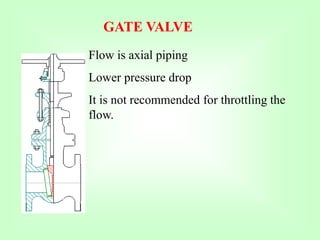

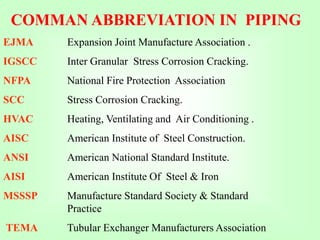

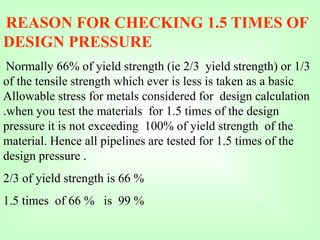

This document provides a summary of topics covered in a presentation on piping systems, including piping components, testing of piping systems, and diagrams used in piping engineering like process flow diagrams and piping and instrumentation diagrams. It discusses different types of pipes and fittings used in piping systems as well as how to accommodate thermal expansion of pipes.