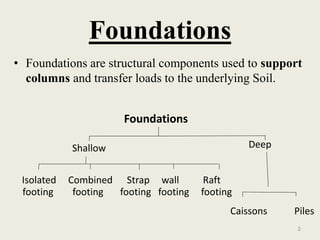

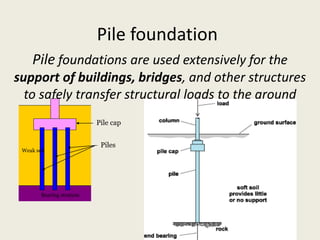

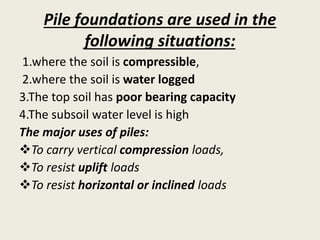

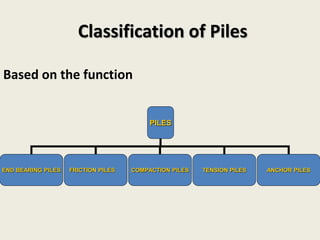

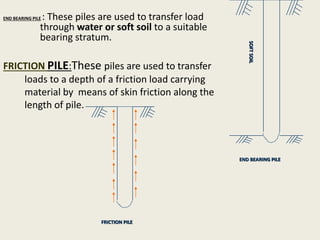

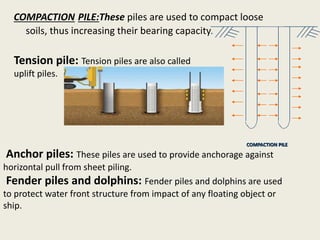

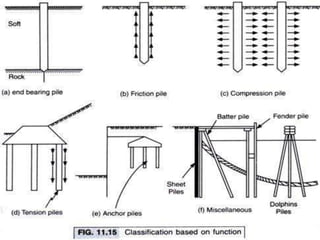

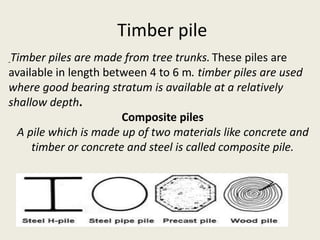

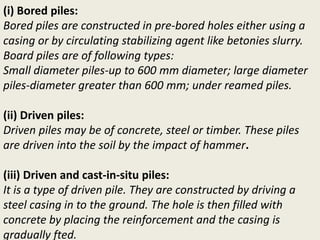

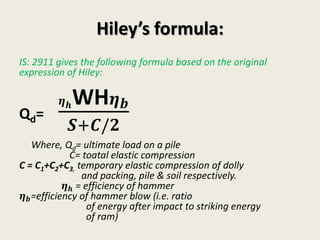

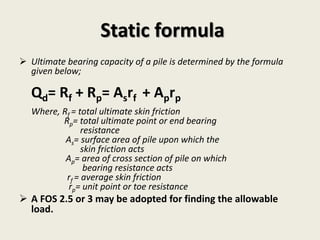

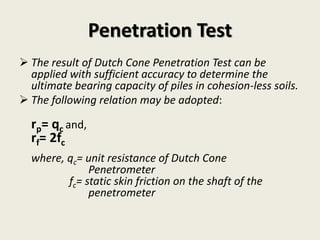

This document summarizes pile foundations. Pile foundations are used to transfer structural loads through weak soil to stronger soil below. There are different types of piles classified by material (concrete, steel, timber), function (end bearing, friction, anchor), and installation method (driven, bored, driven and cast-in-situ). Formulas are provided to calculate the ultimate bearing capacity of a pile based on factors like soil properties, pile dimensions, and hammer efficiency. Selection of the appropriate pile type depends on project specifics like soil conditions, loading, cost, and availability.