Phenol is an organic compound used widely in industry. It is produced at over 7 billion kg per year mainly through cumene synthesis from benzene, propene and oxygen. Its major uses are in producing plastics, resins, nylon and non-ionic detergents. Phenol is slightly acidic and is a precursor to many drugs, herbicides and pharmaceuticals. Exposure to phenol can cause skin and eye burns and internal organ damage. It is toxic in high doses and was even used for executions during WWII. Regulations control phenol levels in wastewater, drinking water and hazardous waste due to its toxicity.

![PHENOL & IT’S COMPOUNDS

Page 3

INTRODUCTION–

Phenol, also known as carbolic acid and phenic acid, is an organic

compound with the chemical formula C6H5OH. It is a

white crystallinesolid at room temperature. The molecule consists of

a phenyl group (-C6H5) bonded to a hydroxyl group (-OH). It is

mildly acidic, but requires careful handling due to its propensity to cause

burns.

Phenol was first extracted from coal tar, but today is produced on an large

scale (about 7 billion kg/year) using industrial processes. It is an important

industrial commodity as a precursor to many materials and useful

compounds.[4]

Its major uses involve its conversion to plastics or related

materials. Phenol and its chemical derivatives are key for

building polycarbonates, epoxies, Bakelite, nylon, detergents and a large

collection of drugs, herbicides and pharmaceuticals

Acidity of phenol-

It is slightly acidic: the phenol molecules have weak tendencies to lose the H+

ion

from the hydroxyl group, resulting in the highly water-

soluble phenolate anion C6H5O−

(also called phenoxide).[5]

Compared

to aliphatic alcohols, phenol is about 1 million times more acidic, although it is still

considered a weak acid. It reacts completely with aqueous NaOH to lose H+

,

whereas most alcohols react only partially. Phenols are less acidic than carboxylic

acids, and even carbonic acid.

One explanation for the increased acidity over alcohols is resonance

stabilization of the phenoxide anion by the aromatic ring. In this way, the negative

charge on oxygen is shared by the ortho and para carbon atoms.[6]

In another

explanation, increased acidity is the result of orbital overlap between the oxygen's

lone pairs and the aromatic system.[7]

In a third, the dominant effect is

the induction from the sp2

hybridised carbons; the comparatively more powerful

inductive withdrawal of electron density that is provided by the sp2

system

compared to an sp3

system allows for great stabilization of the oxyanion.

In making this conclusion, one can examine the pKa of the enol of acetone, which

is 19.0, in comparison to phenol with a pKa of 10.0.[8]

However, this similarity of

acidities of phenol and acetone enol is not observed in the gas phase, and is

because the difference of solvation energies of the deprotonated acetone enol and](https://image.slidesharecdn.com/phenolitscompounds-140624124149-phpapp02/85/Phenol-it-s-Compounds-3-320.jpg)

![PHENOL & IT’S COMPOUNDS

Page 4

phenoxide almost exactly offsets the experimentally observed gas phase acidity

difference. It has recently been shown that only about 1/3 of the increased acidity

of phenol is due to inductive effects, with resonance accounting for the rest.[9]

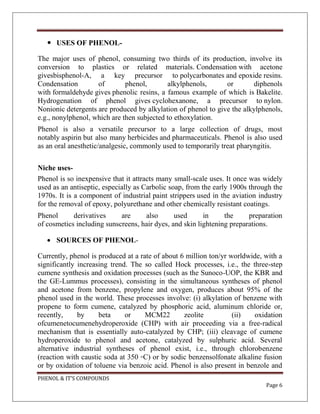

PROPERTIES –

MOLECULAR FORMULA C6H5OH

BOILING POINT 181.7° C

MELTING POINT 40.5° C

DENSITY 1.07g/cm3

APPEARANCE TRANSPARENT CRYSTALLLINE

SOLID

SOLUBILITY IN WATER 8.3g /100ml @ 20° C

FLASH POINT 79° C](https://image.slidesharecdn.com/phenolitscompounds-140624124149-phpapp02/85/Phenol-it-s-Compounds-4-320.jpg)

![PHENOL & IT’S COMPOUNDS

Page 8

economic . No evidence exists to indicate that phenol has any carcinogenic

potential.

Phenol irritates skin and causes its necrosis, it damages kidneys, liver, muscle and

eyes. Damage to skin is caused by its coagulation related to reaction to phenol with

aminoacids contained in keratin of epidermis and collagen in inner ski]. In a dose

of 1 g phenol may be lethal for an adult man, but individual tolerance for this

compound can be high. Some reports reveal that a man can survive even after

administration of 30 g of this compound (60 ml of 50% solution). In regard to fast

absorption by skin (from 60%-90%) even contact of hand or forehand with phenol

solution may cause death . Acute poison with phenol is characterized by dryness in

throat and mouth, dark-coloured urine and strong irritation of mucous membranes.

The investigations showed that chronic administration of phenol by animals leads

to pathological changes in skin, esophagus, lungs, liver, kidneys and also

urogenital tract. Described changes are mainly induced by lipid peroxidation that is

responsible for damage and finally degradation of a cell’s membrane.

Chronic exposure of workers to phenol vapours causes anorexia, lost of body

weight, weakness, headache, muscles pain and icterus. Phenol is mainly

accumulated in brain, kidneys, liver and muscles. Two days after phenol

administration it is mainly excreted in unchanged form and also conjugated with

sulphates and glucuronides. Catechol is also considered a strong toxin. Doses of 50

to 500 mg/kg of body weight usually cause death. For mice after oral

administration of catechol LD50 is 260 mg/kg of body weight.

Acute poison with chlorophenols is characterized by burning pain in mouth and

throat, white necrotic lesions in mouth, esophagus and stomach, vomiting,

headache, irregular pulse, decrease of temperature and muscle weakness,

convulsions and death . Chronic exposure to chlorophenols cause hypotension, fall

of body temperature, weakness and abdominal pain. Poisoning by chlorophenols

results in damage to lungs, liver, kidneys, skin and digestive tract. Strong toxicity

of chlorophenols is expressed by very low, acceptable daily intake (ADI) for

pentachlorophenol that was established for 16 μg for a man of 70 kg of

bodyweight. LD50 for male and female of rats after oral administration of PCP is

14 mg and 3.85 mg/kg of bodyweight respectively . For 2,4,5-trichlorophenol

LD50 is much higher and is of 820 mg/kg of body weight, . Air pollution with a

mixture that contained 2-chloro-6-fluorophenol is the result of an accident in a

chemical factory (New York, US A) that caused symptoms like dryness in mouth

and throat, coughs, headaches and abdominal pain. Chlorophenols undergo fast](https://image.slidesharecdn.com/phenolitscompounds-140624124149-phpapp02/85/Phenol-it-s-Compounds-8-320.jpg)