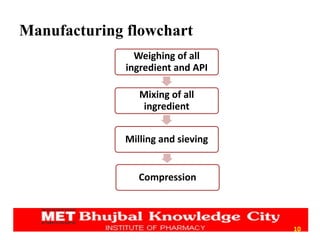

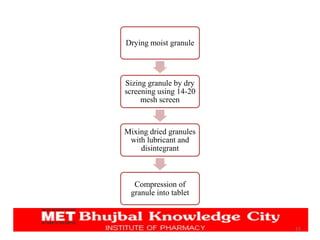

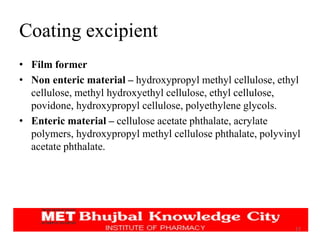

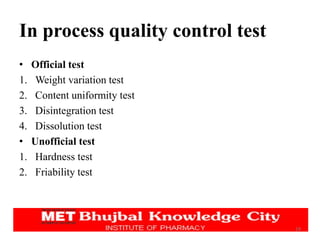

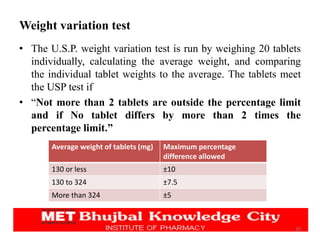

This document provides information on the manufacturing process and quality control testing of tablets. It begins with an introduction to tablet manufacturing methods such as direct compression, dry granulation, and wet granulation. It then outlines the typical manufacturing flowcharts and unit processes for each method. The document also describes in-process quality control tests conducted on tablets including weight variation, content uniformity, disintegration, dissolution, hardness, and friability testing. Common excipients and techniques for tablet coating are also discussed. The document provides a detailed overview of the key considerations and steps involved in tablet production and quality assurance.