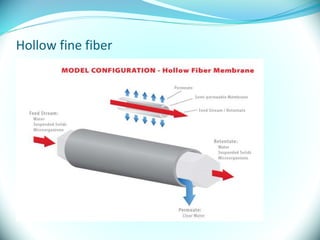

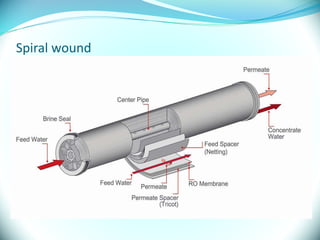

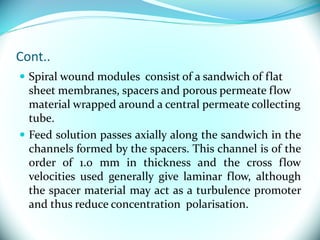

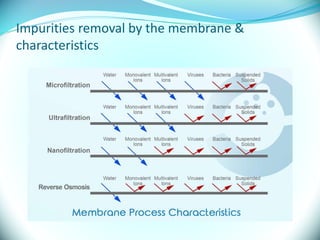

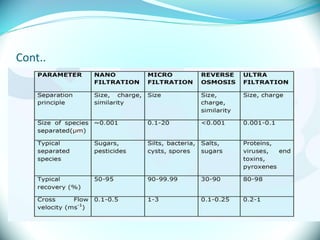

This document discusses membrane technology for water treatment. It describes the basic working principle of membranes, which selectively allow water to pass through while blocking other substances like solids, bacteria, and proteins. There are two main types of membrane modules: hollow fine fiber membranes and spiral wound membranes. The performance of membranes can be affected by factors like pH, pressure, temperature, and feed flow. Regular cleaning is needed to prevent fouling, which is typically done through chemical cleaning processes involving low and high pH cleaners.