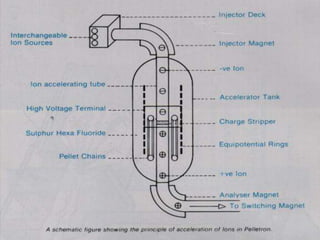

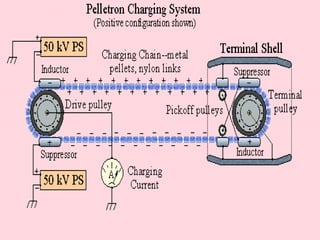

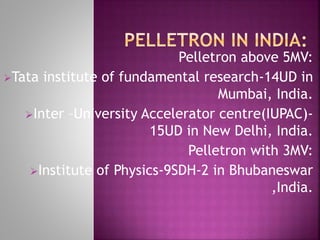

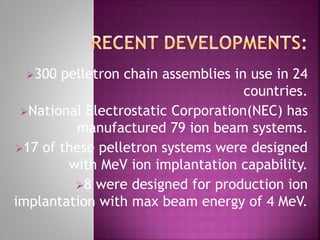

The document discusses the Pelletron electrostatic generator, which accumulates electric charge to create high electric potentials for accelerating subatomic particles in nuclear medicine. It describes the operational mechanism, components, and advantages of the Pelletron, highlighting its usage in various institutions in India and its global presence. The Pelletron systems are noted for their reliability, efficiency, and longevity with minimal maintenance requirements.