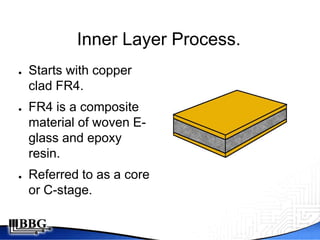

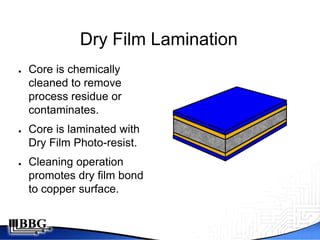

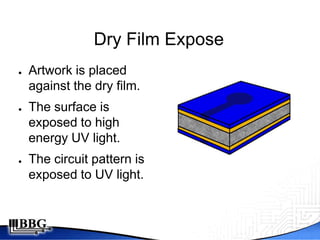

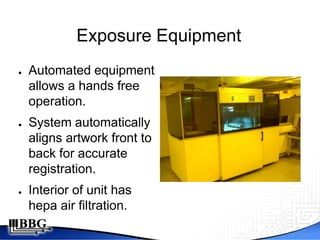

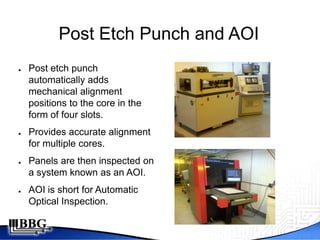

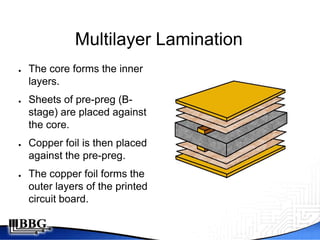

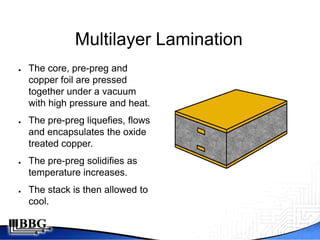

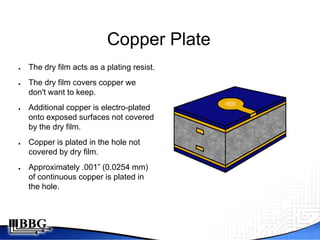

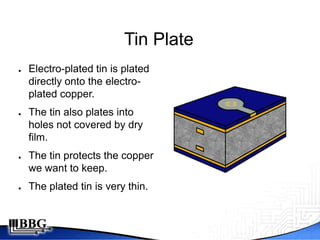

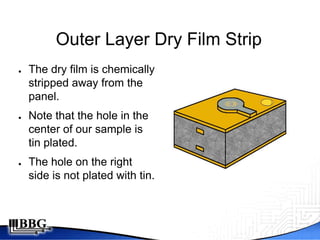

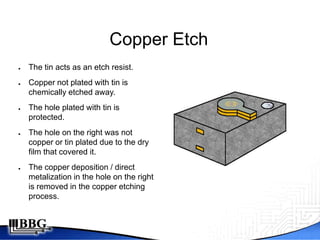

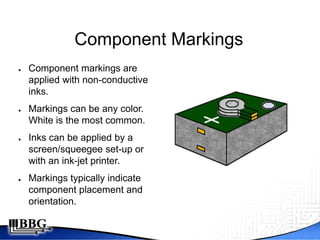

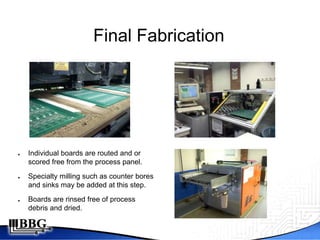

The document outlines the fundamental processes involved in building a printed circuit board (PCB), detailing the materials used, such as copper clad FR4, and the essential steps including dry film lamination, copper etching, multilayer lamination, and various drilling and plating techniques. It describes the equipment used throughout the manufacturing process, emphasizing the importance of chemical treatments and air filtration. Finally, it covers the application of solder masks, component markings, and the final fabrication and testing of the boards.