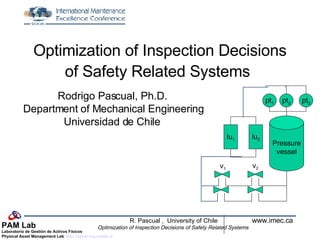

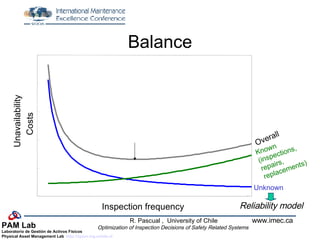

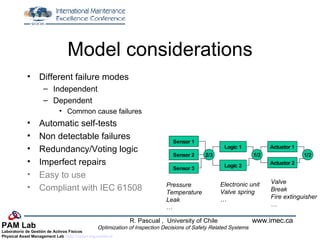

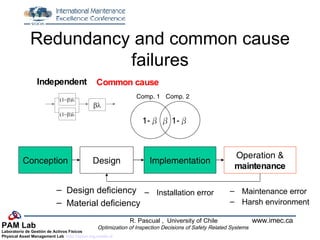

The document discusses optimization of inspection decisions for safety systems. It notes that up to 40% of failure modes in safety systems are hidden and require failure finding tasks. The document then outlines factors to consider in developing reliability models for safety systems, including different failure modes, redundancy, common cause failures, and imperfect inspections. The goal is to estimate optimal inspection intervals to maximize overall availability and safety availability of safety systems. An example is provided of analyzing inspection intervals for a two-out-of-three pressure vessel safety system.