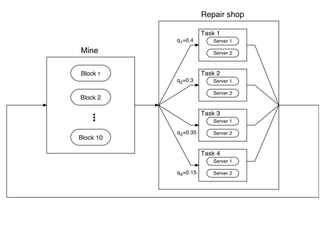

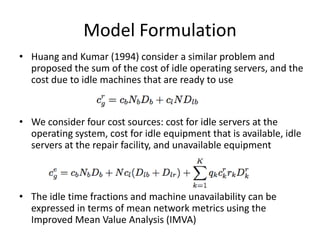

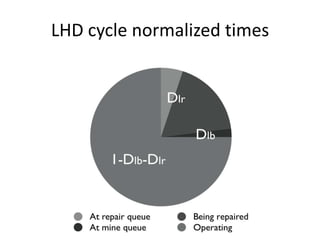

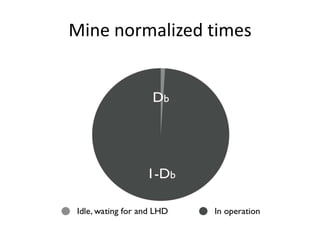

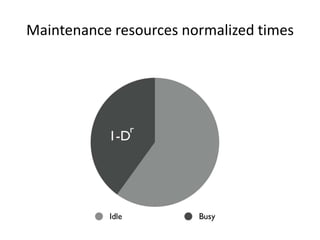

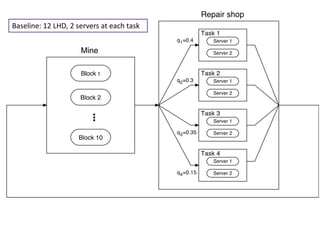

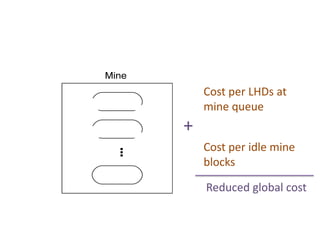

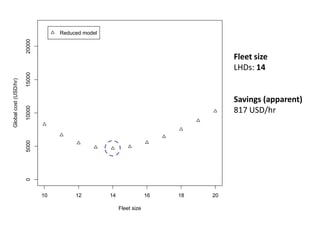

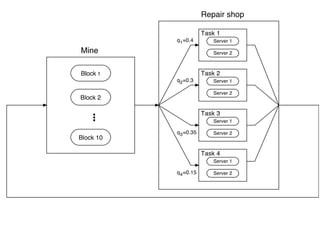

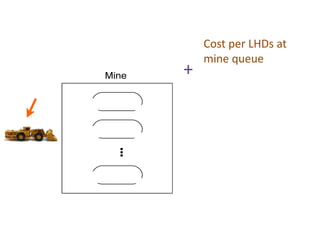

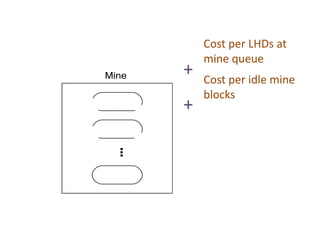

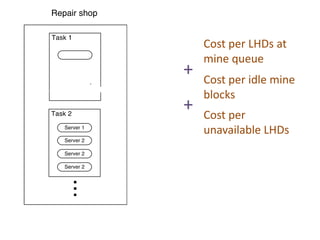

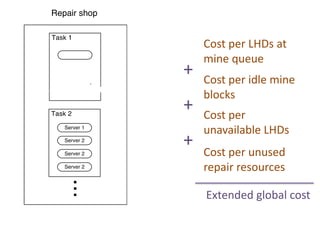

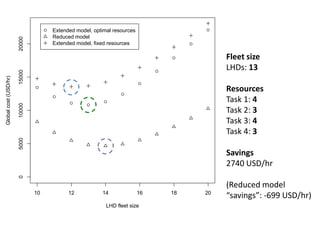

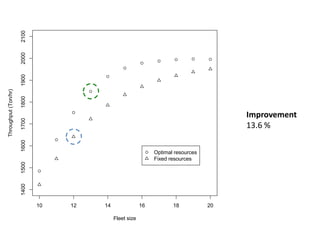

This document summarizes a study that developed a model to jointly optimize fleet size and maintenance capacity for a mining operation. The model considers costs from idle equipment, queues, unused repair resources, and downtime. Applying the model to a case study found that a fleet size of 13 units with optimized repair resource allocation reduced total costs by 2740 USD/hr compared to a baseline. The optimized solution also improved throughput by 13.6%. In conclusion, an integrated approach is needed to manage assets and opportunity costs, and maintenance flexibility allows both cost savings and performance gains.