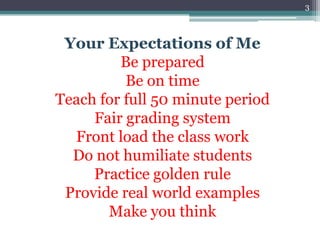

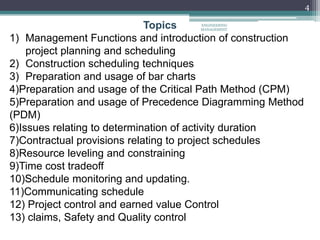

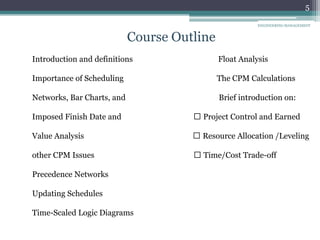

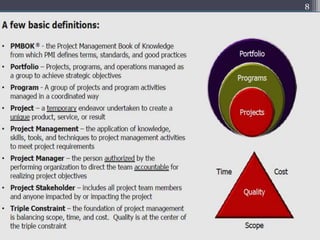

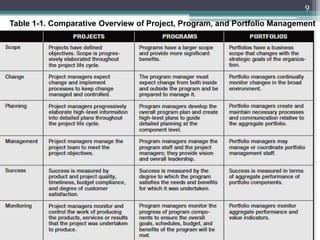

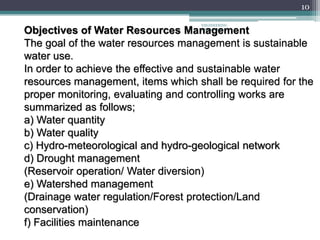

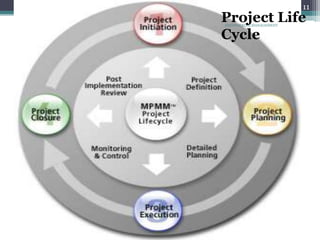

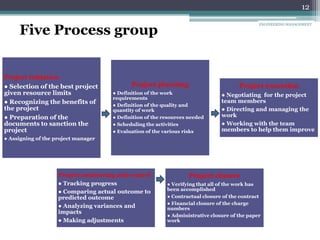

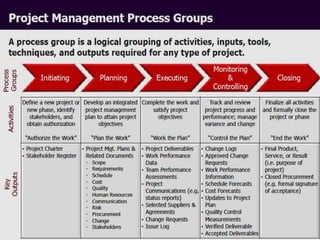

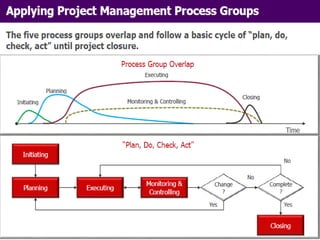

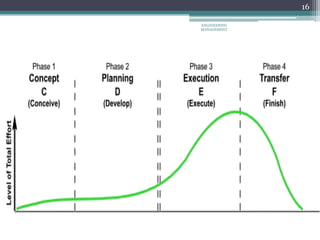

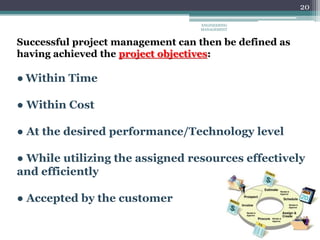

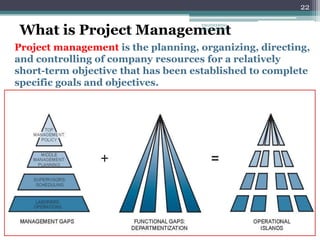

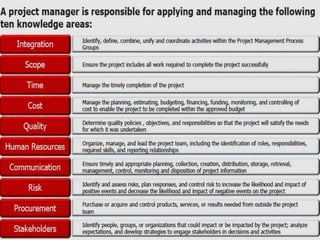

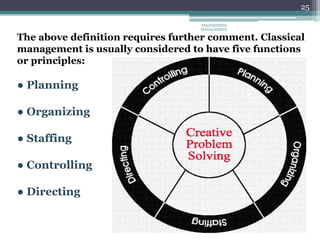

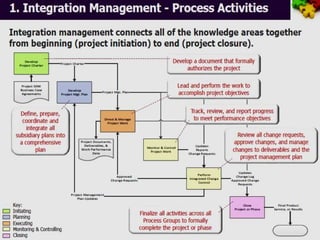

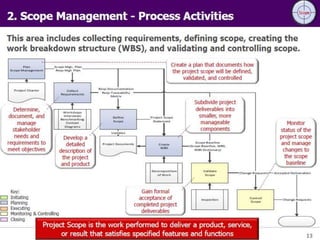

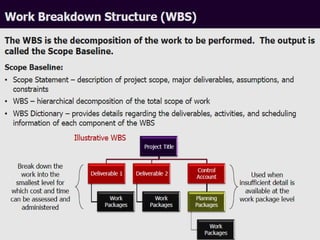

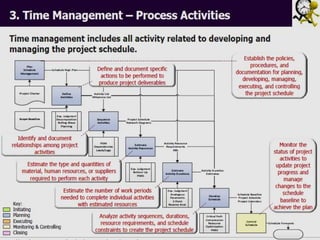

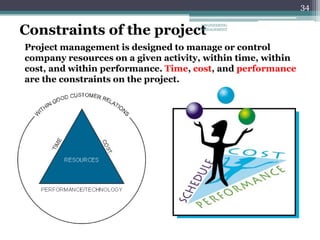

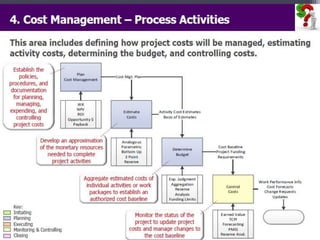

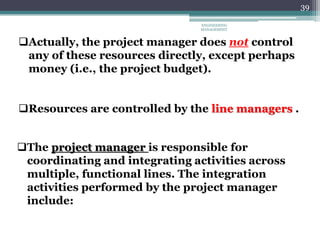

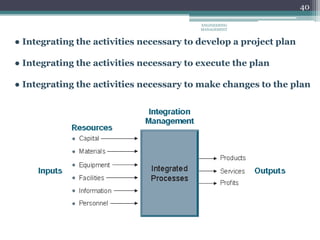

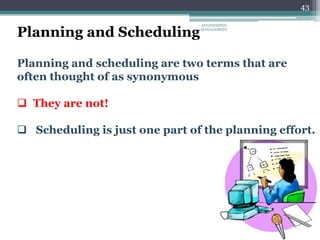

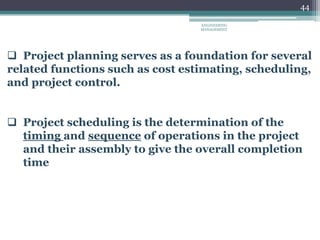

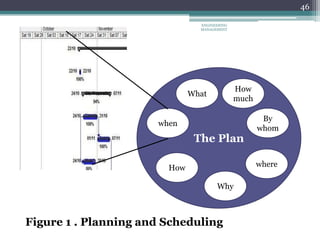

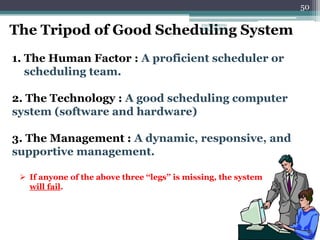

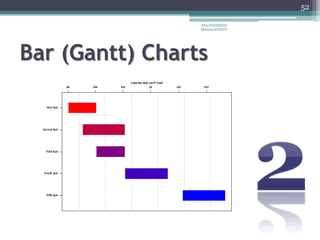

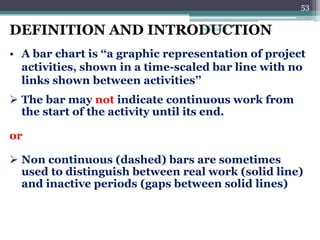

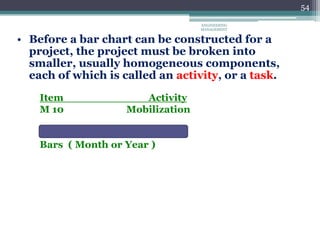

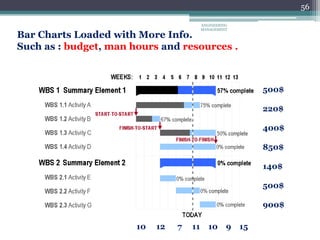

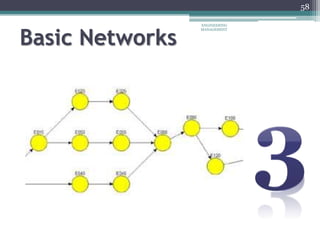

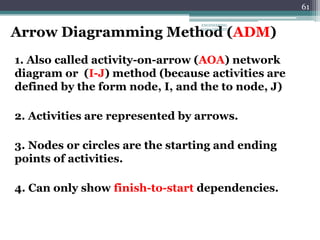

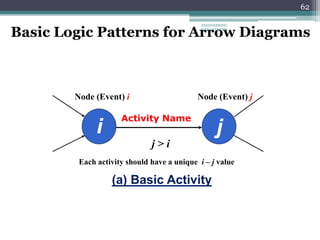

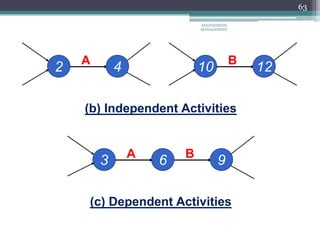

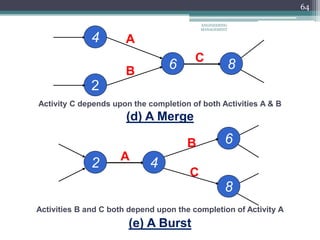

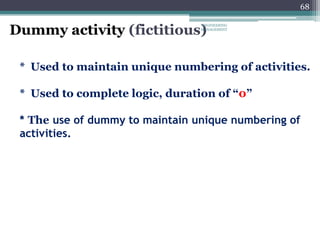

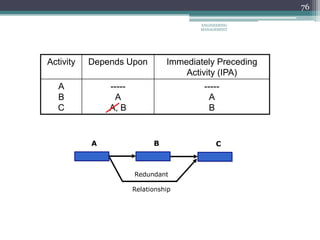

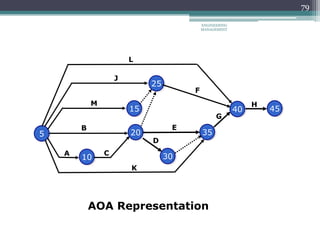

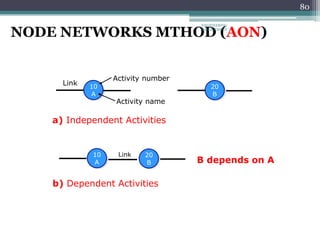

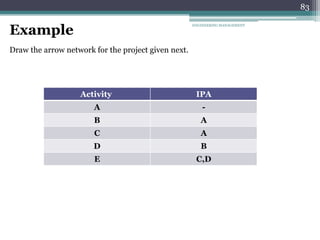

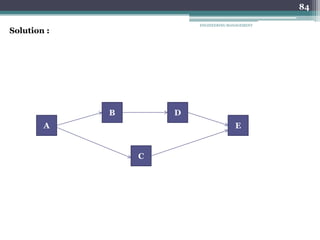

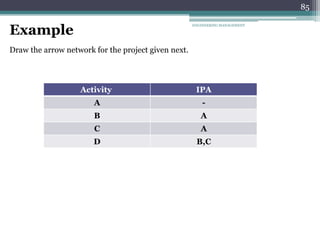

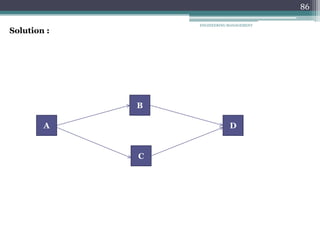

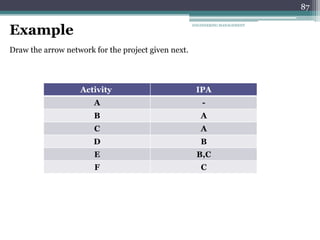

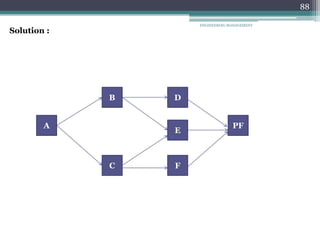

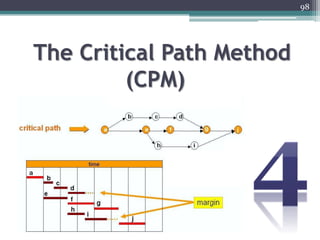

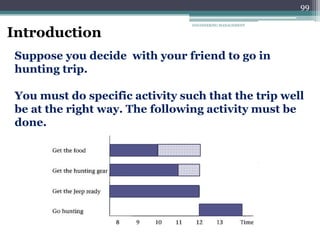

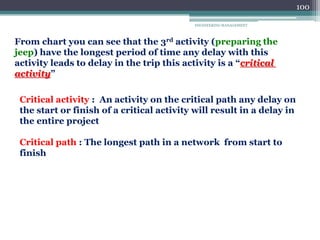

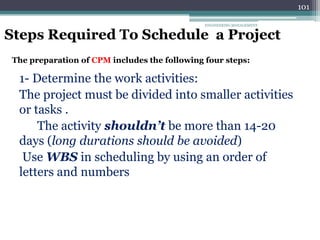

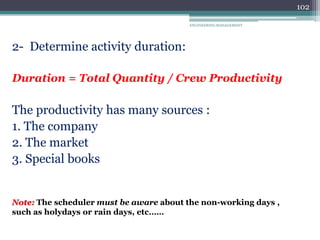

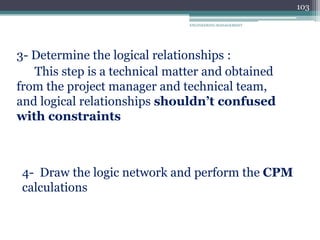

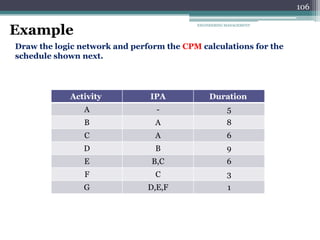

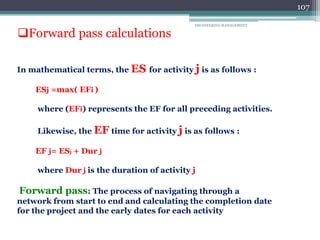

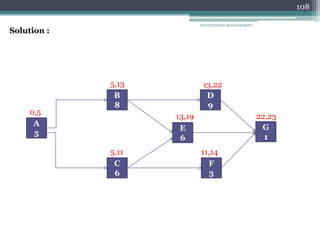

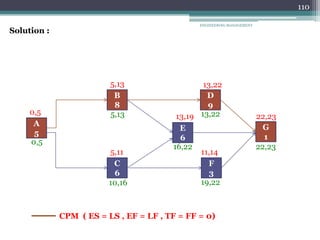

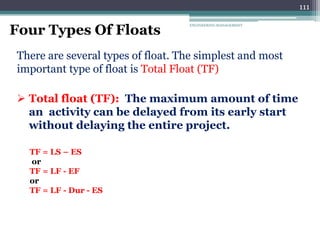

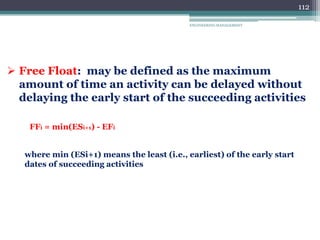

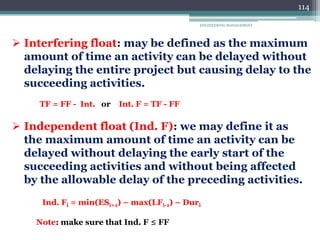

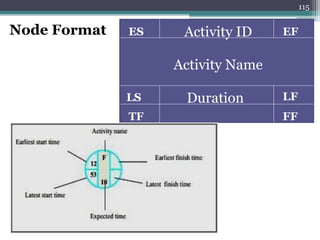

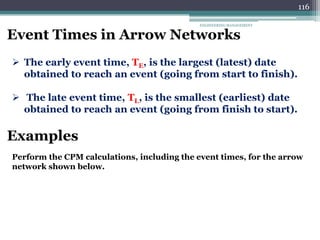

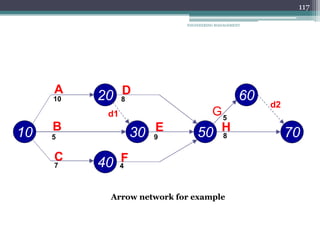

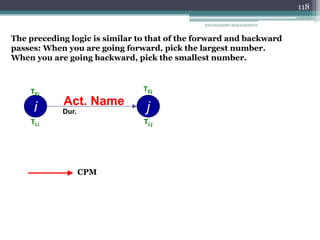

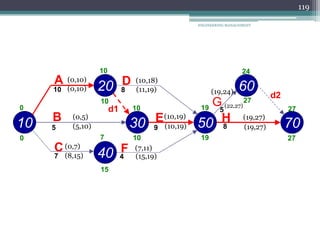

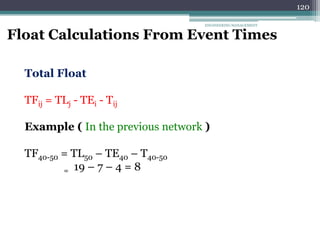

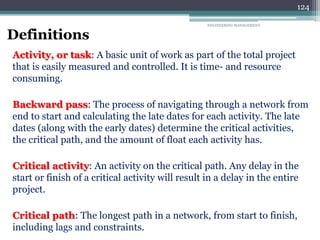

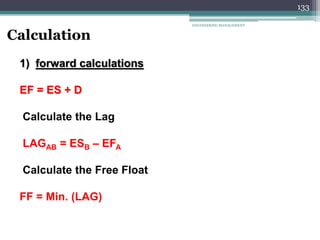

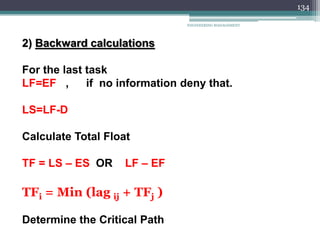

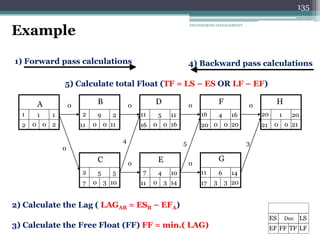

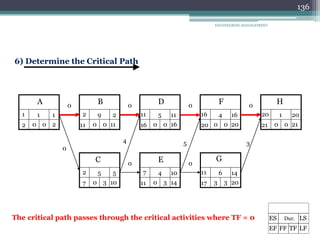

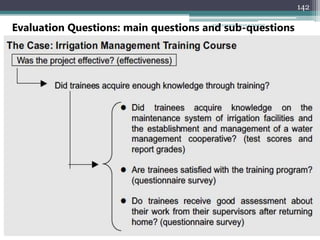

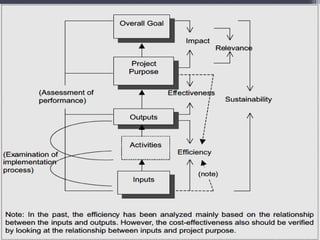

The document outlines a comprehensive course on engineering project management, detailing expectations for students and key topics such as construction scheduling techniques, project control, and the critical path method (CPM). It defines project management, highlights the importance of effective scheduling, and discusses the elements necessary for successful water resources management. Various project management tools including bar charts, networks, and critical path analysis are also emphasized to aid in planning and execution.