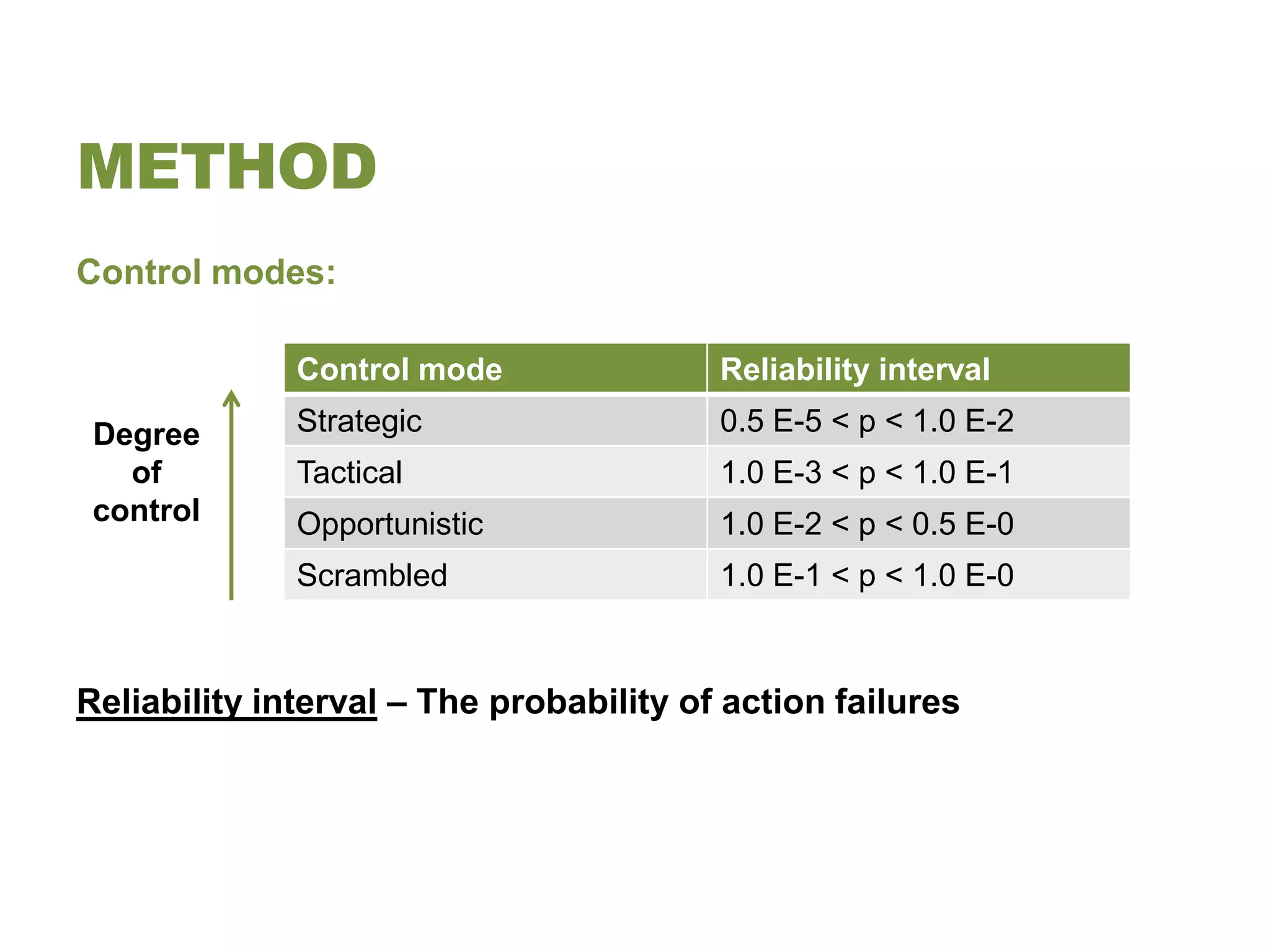

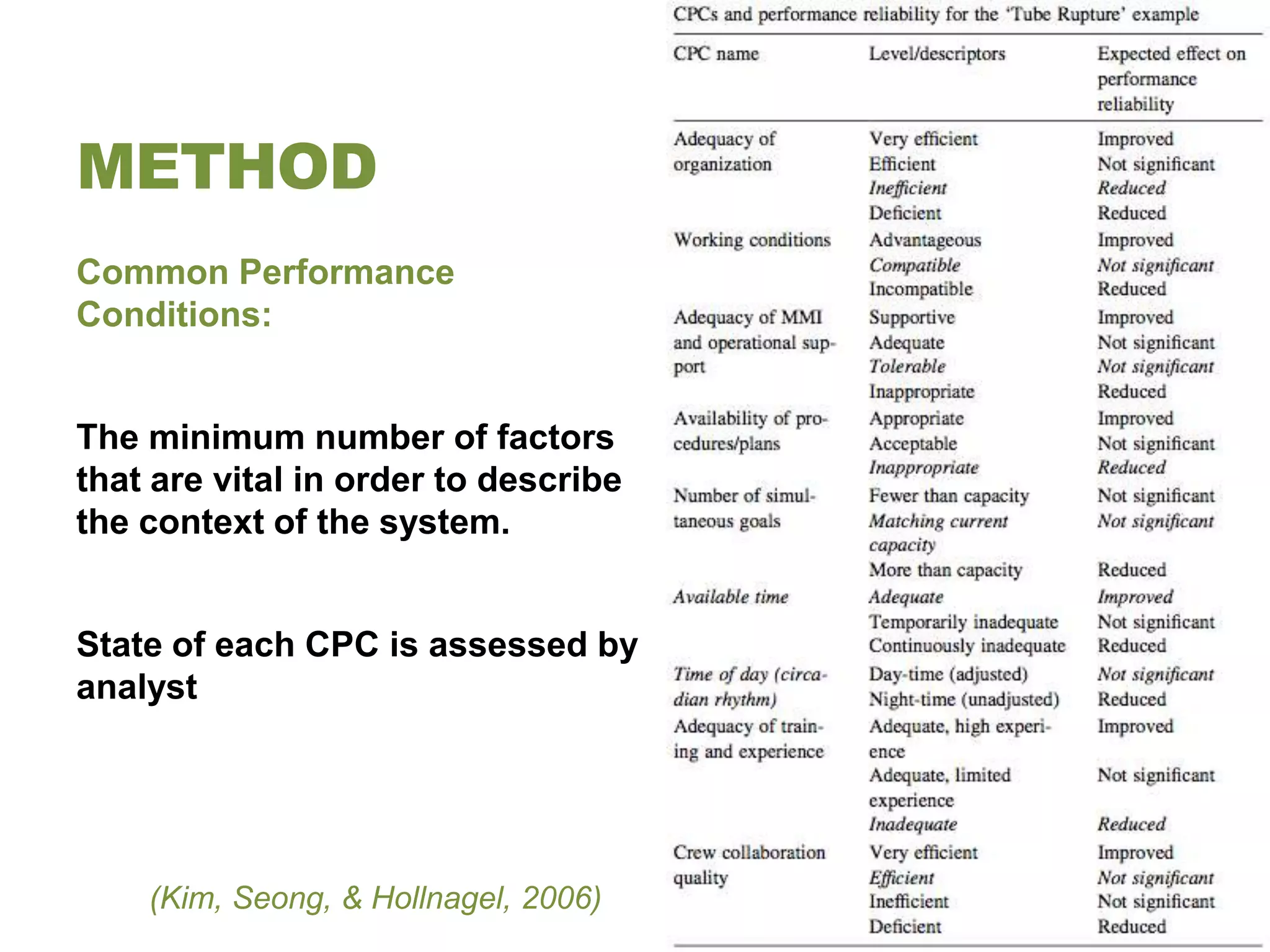

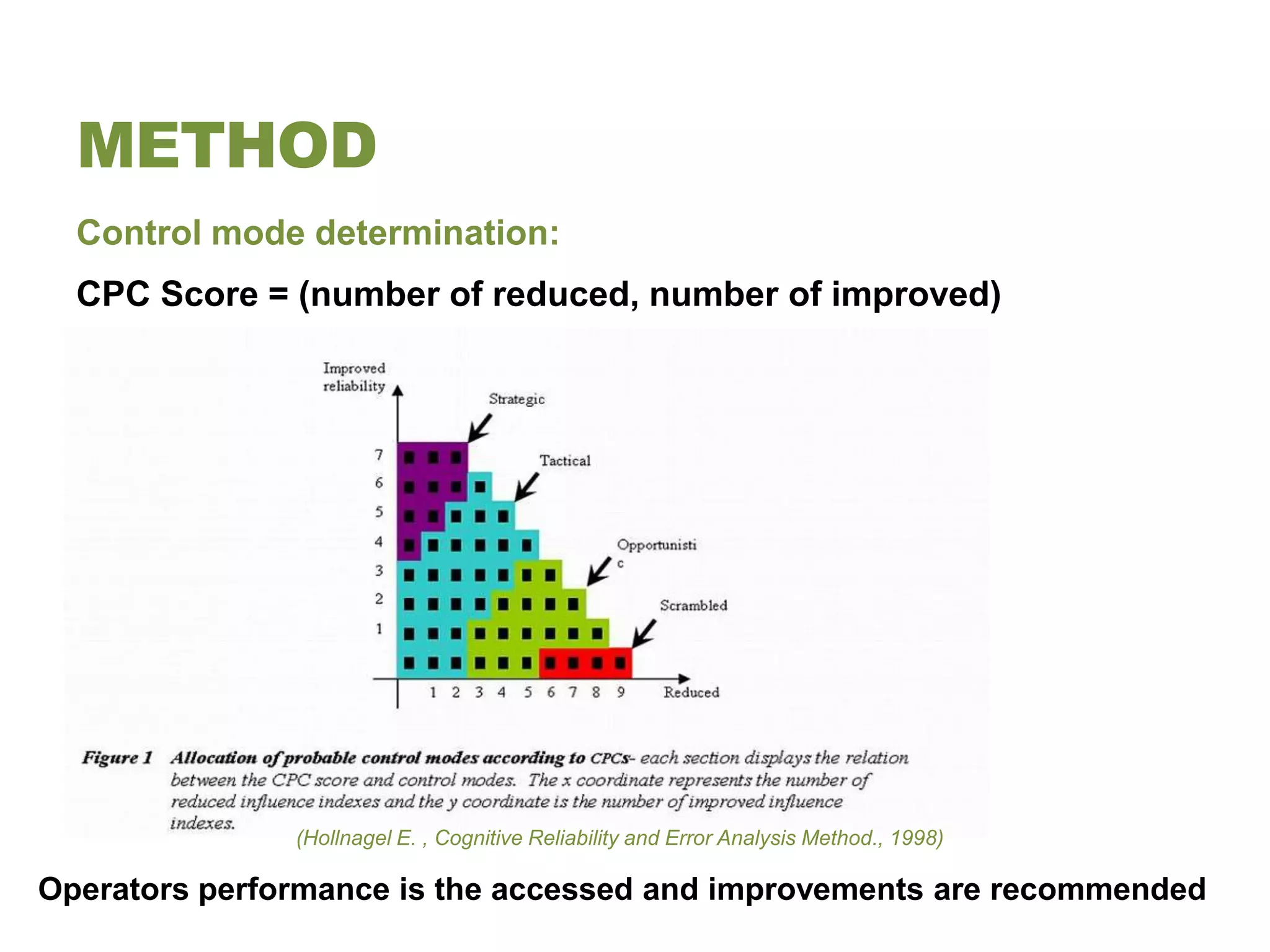

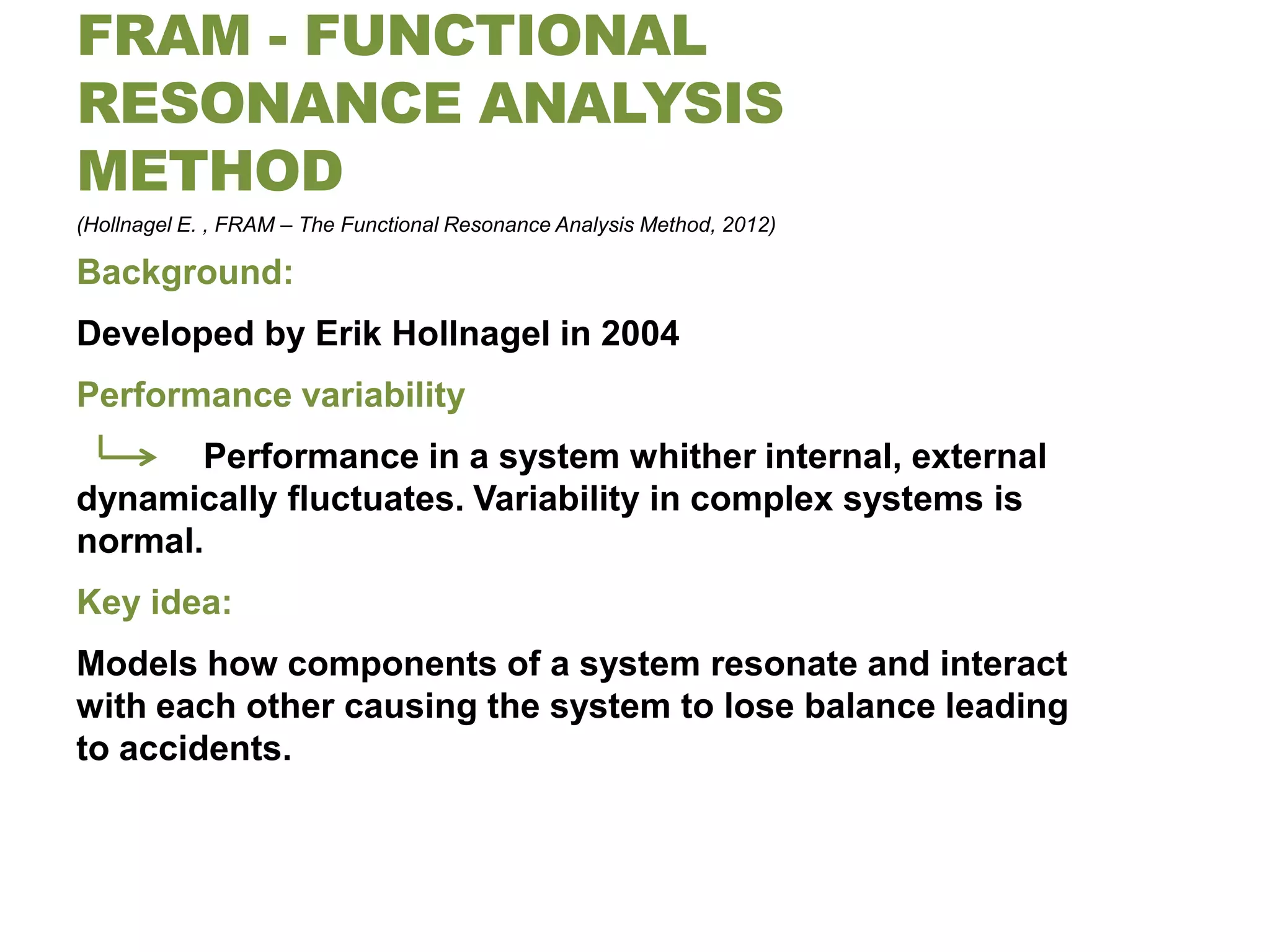

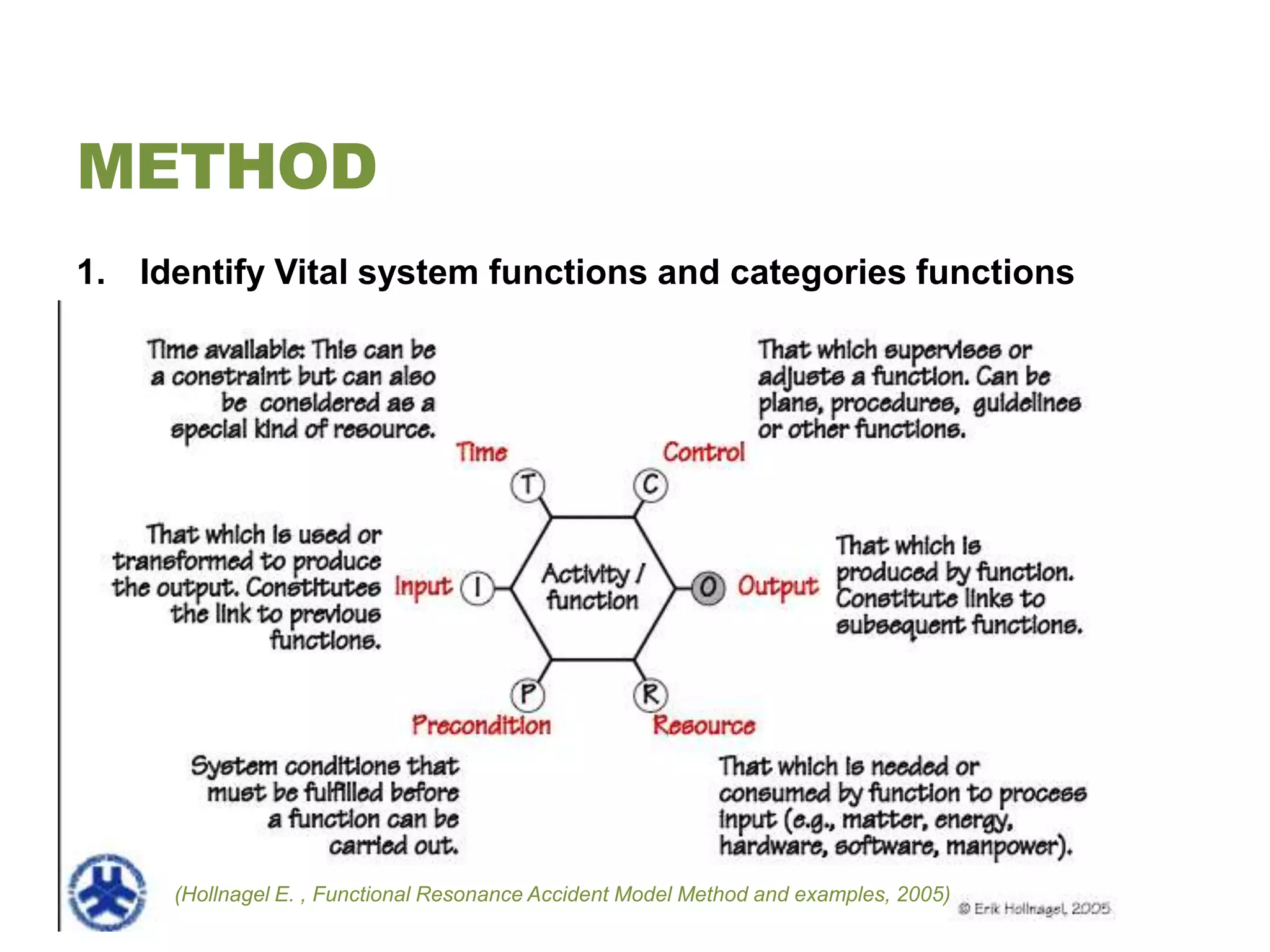

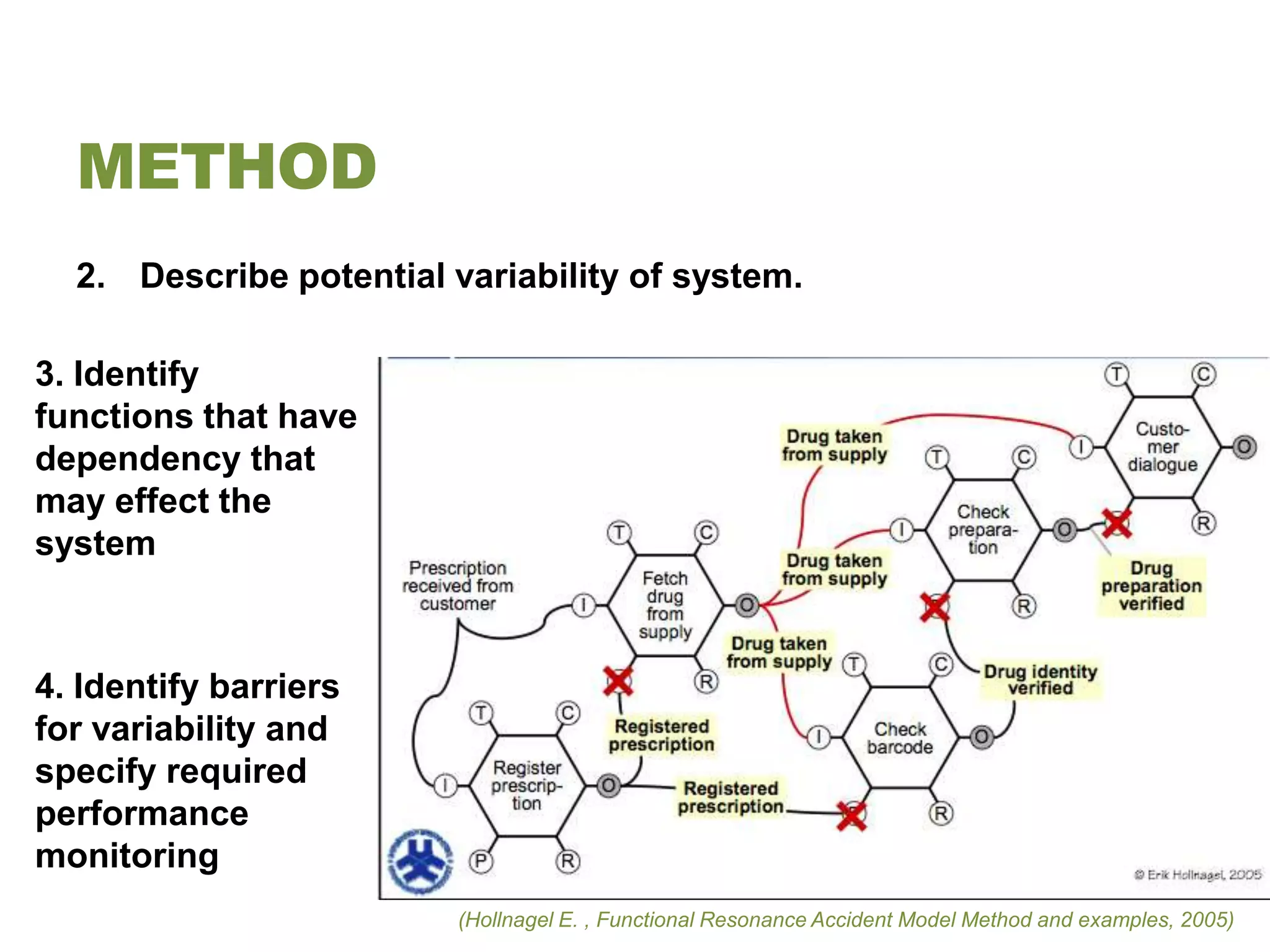

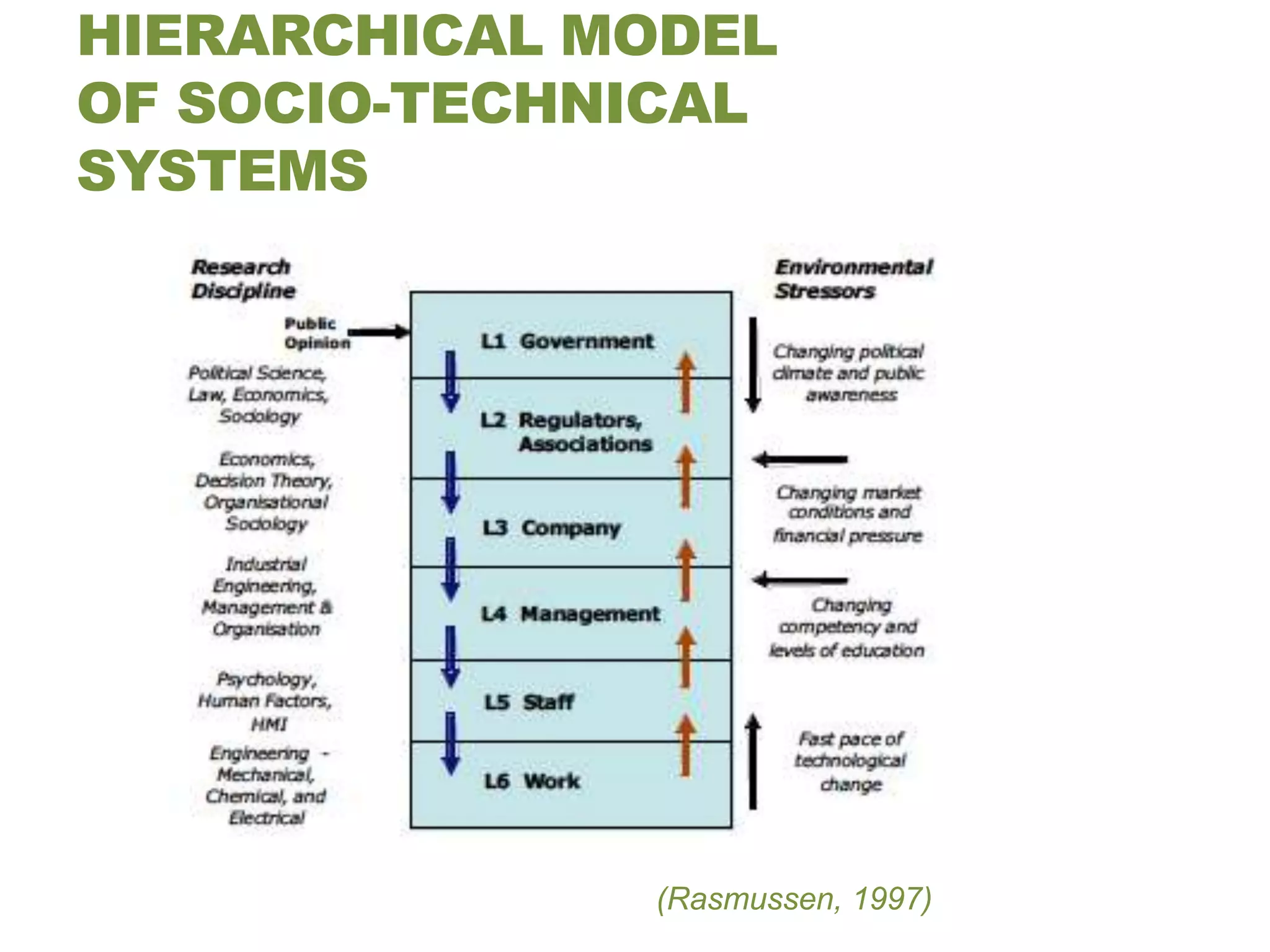

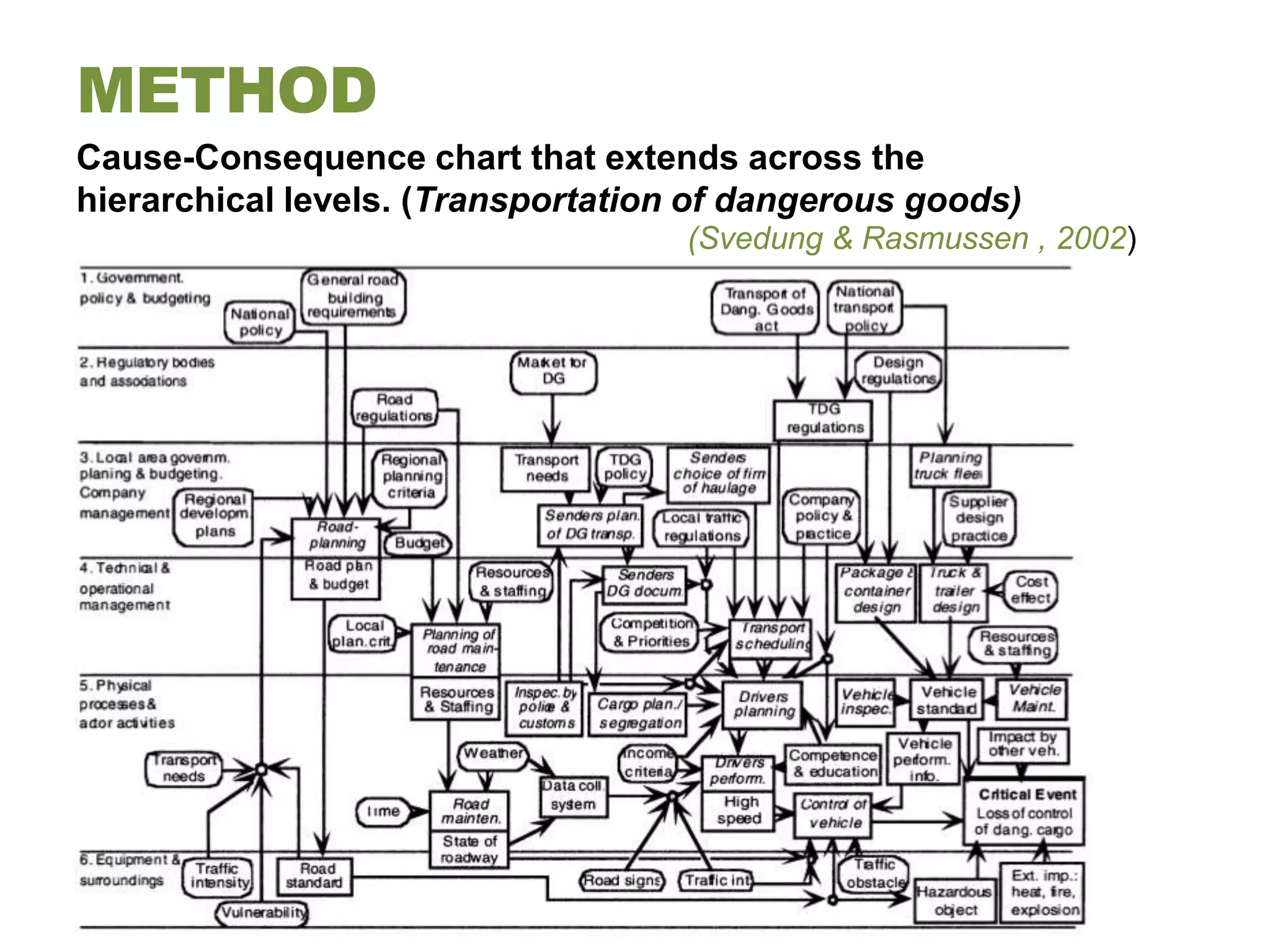

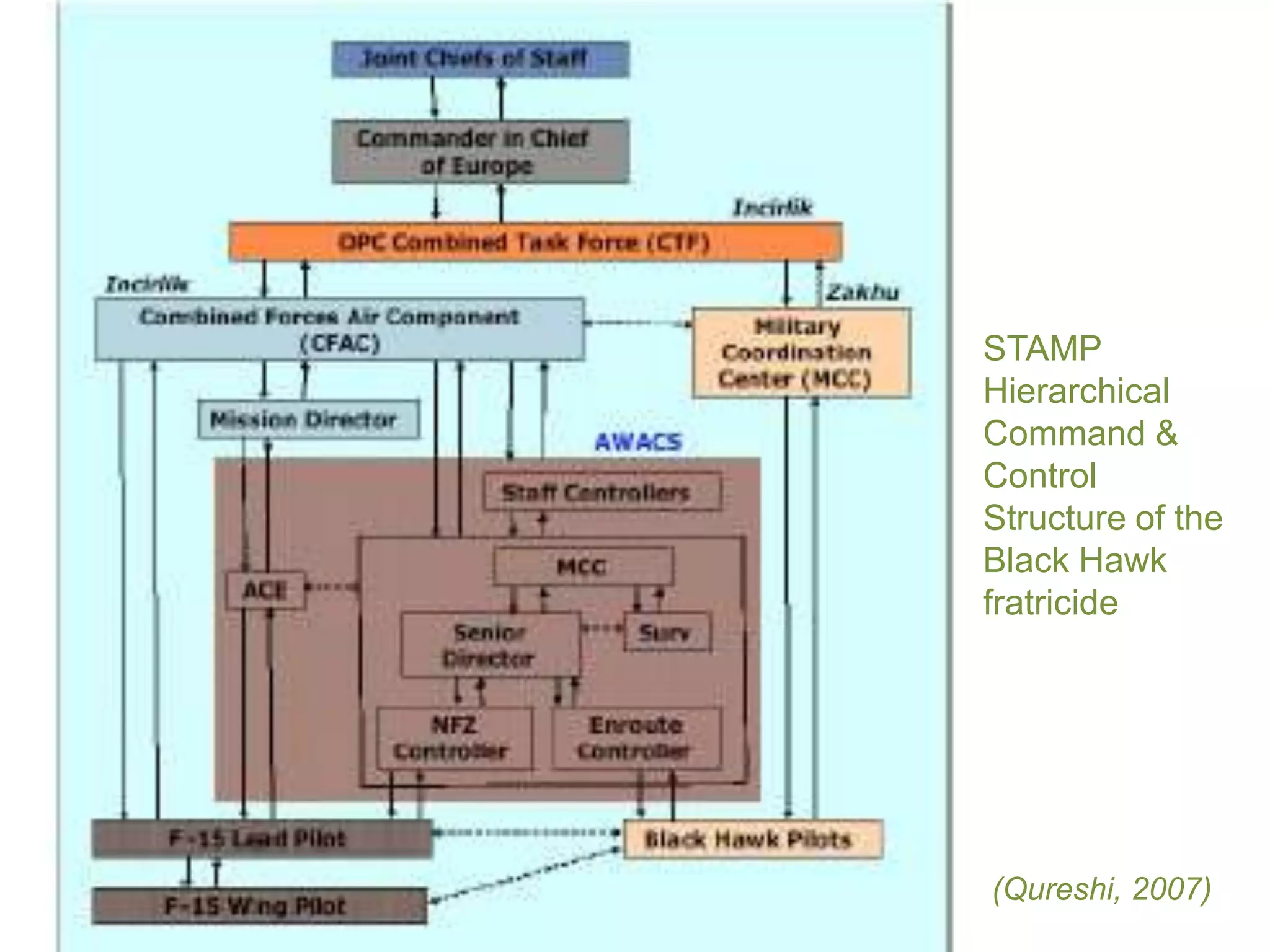

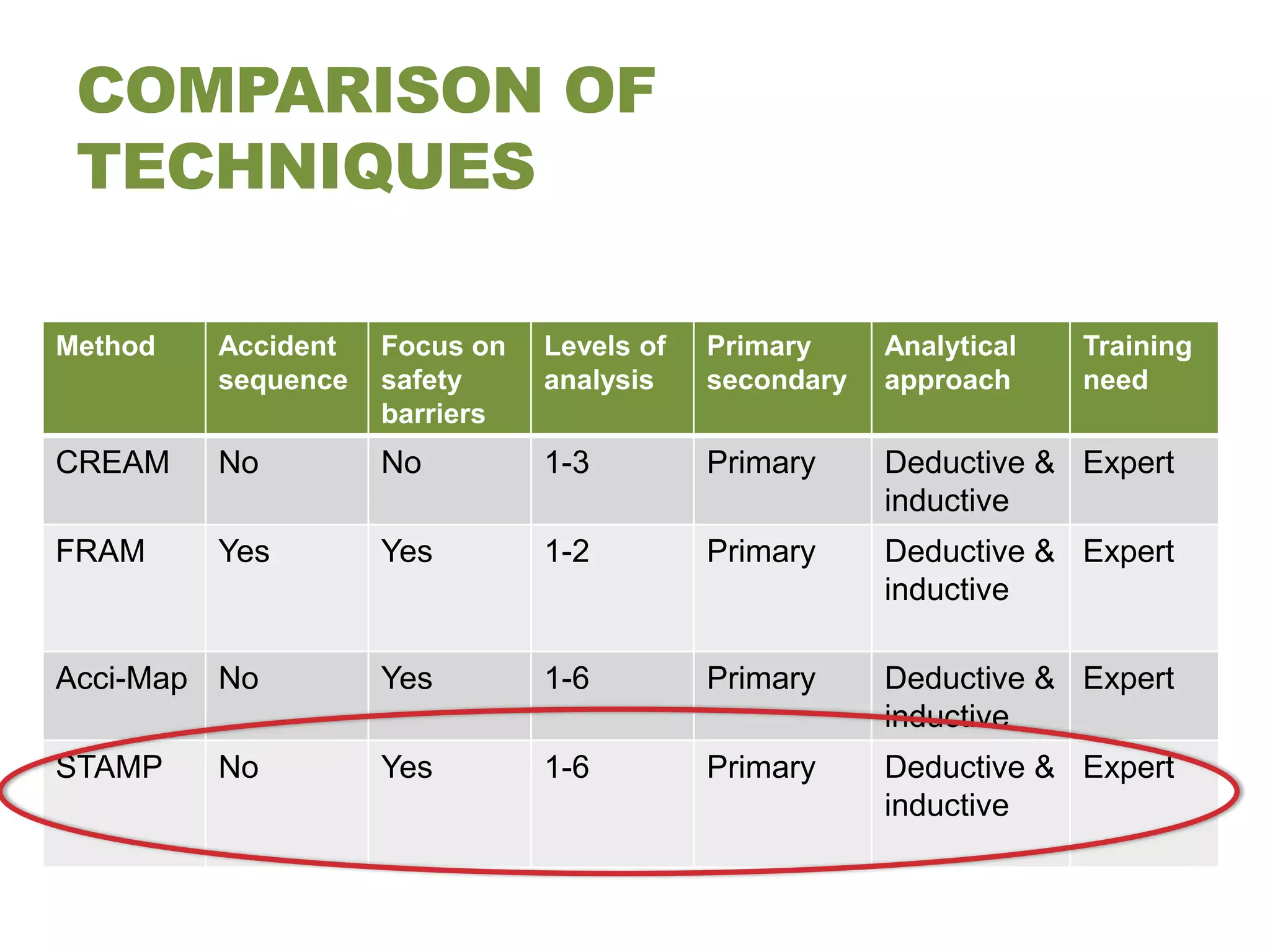

This document provides an overview of four systemic accident modeling techniques: CREAM, FRAM, AcciMap, and STAMP. It discusses the background, key ideas, and methods for each technique. It also expands upon a framework for comparing accident modeling techniques, analyzing the techniques on factors like accident sequence consideration, safety barrier focus, analytical levels and approaches, and training needs.