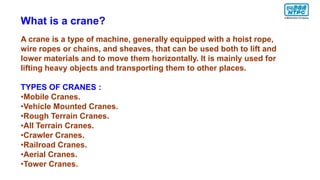

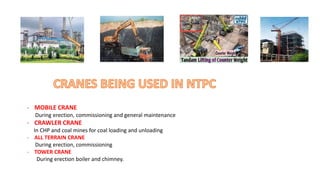

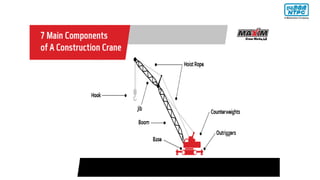

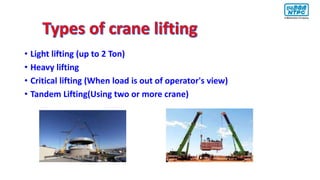

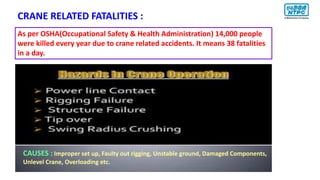

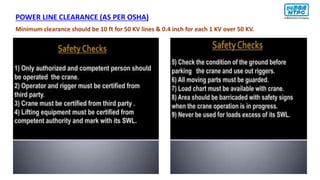

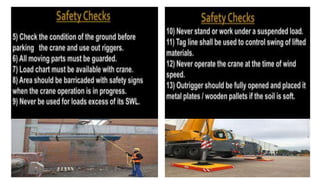

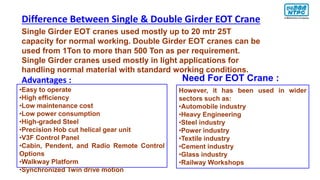

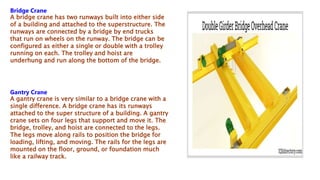

Lifting tackle refers to equipment used for lifting loads, including slings, hooks, shackles, and other appliances. Common lifting tools include lifting hooks, clamps, shackles, chain slings, and rope slings. It is important to inspect lifting tools before use and not exceed their safe working load. Overhead cranes come in various types and are used to safely lift and move heavy loads over long distances in industrial facilities. Proper inspection and following safety procedures are required when operating cranes and other lifting equipment.