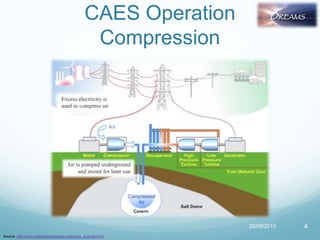

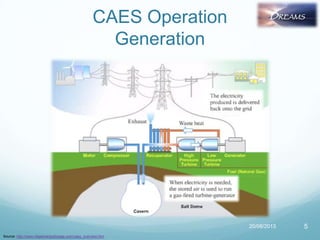

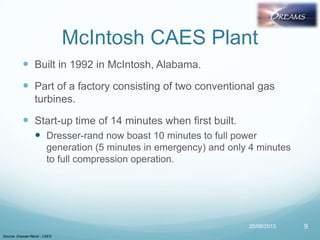

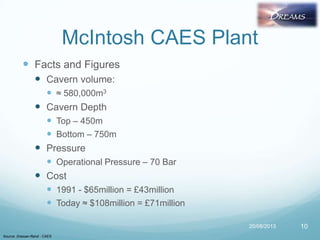

Compressed air energy storage is a method for storing renewable energy by compressing air and storing it in underground caverns or above ground tanks. The document discusses several existing CAES plants including Huntorf, Germany (1978) and McIntosh, Alabama (1992). It also outlines several proposed CAES projects in locations such as Texas, Ireland, Ohio, and California. CAES provides advantages such as quick start-up times, shifting cheap off-peak energy to expensive peak times, and utilizing excess renewable energy that would otherwise be wasted.

![General

Compression Technology

Have researched and designed the General

Compression Advanced Energy Storage (GCAESTM)

system1.

Based on reversible thermodynamics, they claim a near-

isothermal process, covering both the compression and

expansion stages.

Efficiency – 75%

Cost – $800 - $1000/kW2

Have a fully operational 100kW multi-stage plant in

Watertown, Massachusetts.

Construction of second generation GCAES, 2MW, 500MWh

system with wind turbine integration now underway in Texas.

20/08/2013 16

[1] Source: General Compression – Who We Are

[2] Source: General Compression - Fuel-Free Geologic Compressed Air Energy Storage From Renewable Power - Task #1 Deliverable Report](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-16-320.jpg)

![Iowa Stored

Energy Park

Planned project studied for 8 years to store wind

energy through compression of air in sandstone

aquifers below the ground.

Power Output: 270MW

$400million4

Project terminated in 2011 due to geology reasons.

20/08/2013 17

[4] Source: Sandia Report – Lessons from Iowa](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-17-320.jpg)

![Larne, Ireland

A planned gas storage system by InfraStrata and North

East Storage that was subject to heavy opposition due

to the disposal of brine in the sea, amongst many other

safety concerns3.

Gaelectric have now carried out tests to determine the

feasibility of the area for CEAS.

£175million project

£10million set aside for feasibility study

Power Output: 140 - 300MW

20/08/2013 18

[3] Source: Larne Times – Test Data will Provide Data on Wind-Energy Storage Potential](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-18-320.jpg)

![New York Power

Authority Research

Provide around 25% of the energy requirements of

New York State, and are looking to supply renewable

energy options to all their customers.

Mission statement:

“to advance the generation and utilization of renewable

energy through project implementation, research and

technology transfer”8

20/08/2013 19

[8] Source: New York Power Authority - Energy Storage Activities at New York Power Authorities](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-19-320.jpg)

![ Underground CAES feasibility study8

Power Output: 300MW

Compressor Power: 215MW

Storage Capacity: 10 hours

Cost: $700/kWh

Above ground CAES feasibility study

3 foot diameter 2 mile pipework

Power Output: 10MW

Storage Capacity: 2hours

20/08/2013 20

New York Power

Authority Research

[8] Source: New York Power Authority - Energy Storage Activities at New York Power Authorities](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-20-320.jpg)

![Norton, Ohio CAES

Project

This project has been researched for over a decade

now, changing company hands with current owners

First Energy.

The proposal7:

CAES in a disused Limestone mine

Power Output: 270MW initially rising to 2700MW as more

and more phases are built.

20/08/2013 21

[7] Source: First Energy Corporation – Alternative and Renewable Energy](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-21-320.jpg)

![San Joaquin County

CAES Site Testing

Pacific Gas & Electric Company (PG&E) spent three

weeks conducting tests on a depleted natural gas

reservoir, capable of storing 300MW of power lasting

10 hours5.

Engineers and geologists have been studying 10m

sections of rock in order to determine the feasibility of

CAES, as has to be the case with all CAES projects6.

Results are yet to be published.

20/08/2013 22

[5] Source: Energy Storage Exchange - Advanced Underground CAES Project w/Saline Porous Rock Formation

[6] Source: PGE Currents- Electricity Out of Thin Air? PG&E Exploring New Type of Clean Energy](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-22-320.jpg)

![SustainX CAES

Demonstration Project

Small start-up company who raised $14.4million and

received a grant from US DoE of $5.39million,

highlighting the recognition for such projects to be

developed9.

A 50kW plant has already been built and now

construction has begun on a 1MW, 4MWh plant10.

Built using SustainX‟s patented Isothermal technology,

boasting the lack of fuel and secondary heat sources

involved.

95% efficiency in both compression and expansion.

20/08/2013 23

[9] Source: Gigaom - SustainX Raises $14.4M for Air Energy Storage

[10] Source: US DoE – SistainX Inc - Isothermal Compressed Air Energy Storage](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-23-320.jpg)

![Advantages of CAES

Reduces the costs in having no storage at all, thus reducing

wind curtailment.

In 2011, wind farms were paid £25million to not produce

electricity due to extortionately high costs set by the wind farm

operators1.

This money could be spent on installing CAES systems and so

the turbines would be able to store the energy produced, thus

eliminating costs for shut-down.

Reduced emissions associated with the energy produced by

conventional methods.

Storing energy that would otherwise be wasted results in a

reduction in emissions due to needless further production.

20/08/2013 24

[1] Source: Daily Mail – “Wind farms paid £25million NOT to produce electricity when it is blustery - and YOU pay”](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-24-320.jpg)

![Advantages of CAES

Quick start-up time.

0%-100% can be achieved in 10 minutes.

50%-100% can be achieved in 15 seconds2.

Vast areas in which the system could be implemented

80% of US territory has geology suitable for CAES3.

There just needs to be a proven technology with high

efficiency that could be applied to the possible sites.

20/08/2013 25

[2] Source: Arizona Research Institute for Solar Energy

[3] Source: Boise State University - “Overview of Compress Air Energy Storage”](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-25-320.jpg)

![Advantages of CAES

Using Salt Caverns

Flexibility4

Operate under very high pressure and so can very quickly

accept or deliver large amounts of air and hence can cope with

the intermittency of generation requirements caused by

renewable sources.

Cycling

Traditional gas caverns can traditionally only inject in the

summer and withdraw in the winter

Base Gas

Caverns must be primed with a base pressure of gas, which is

lower in salt caverns than it is with typical caverns, resulting in a

higher proportion of working gas from the cavern.

20/08/2013 27

[4] Source: EIA – “Salt caverns account for 23% of U.S. underground natural gas storage daily deliverability”](https://image.slidesharecdn.com/overallpresentation-130820122534-phpapp02/85/Overall-presentation-27-320.jpg)