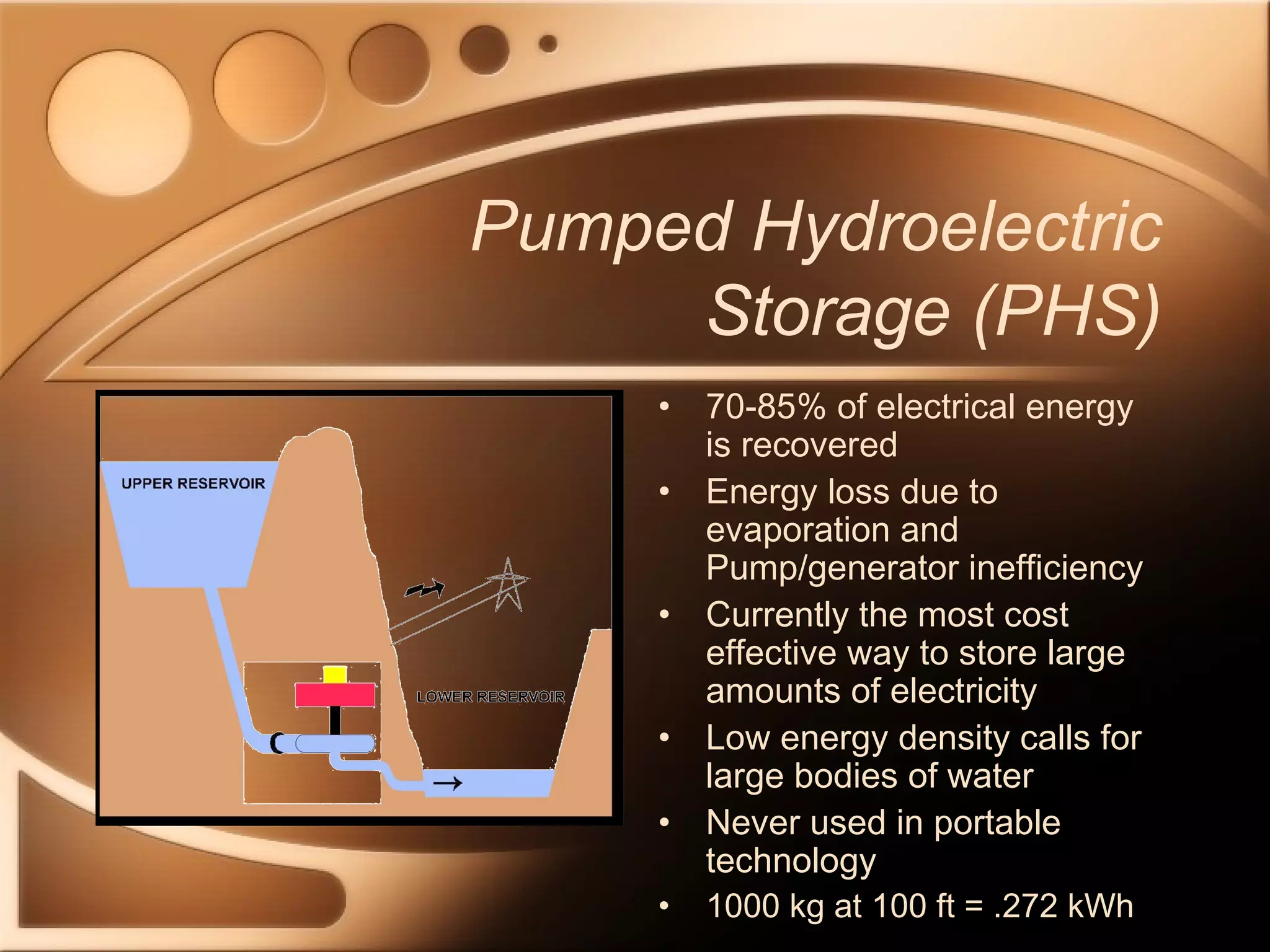

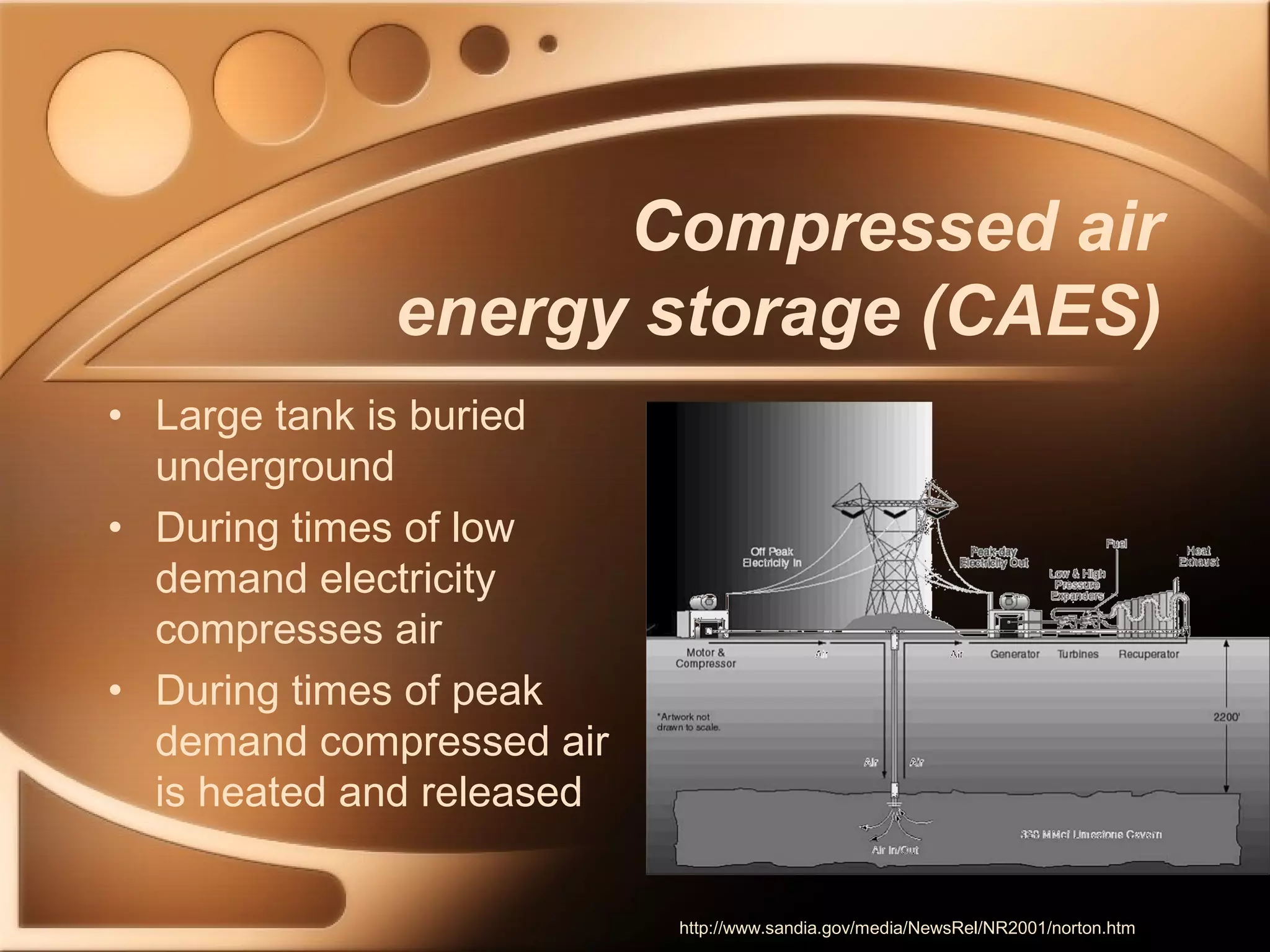

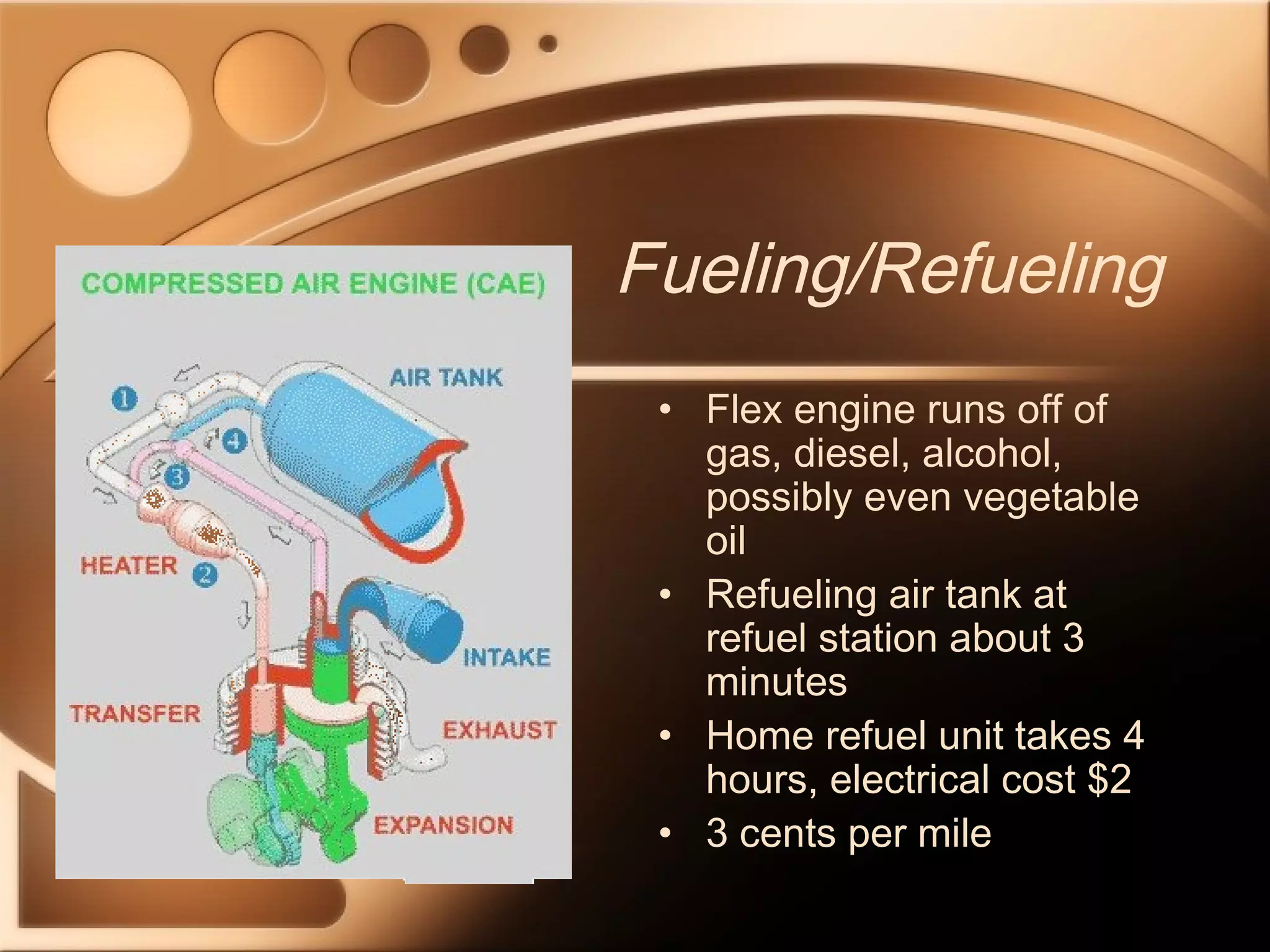

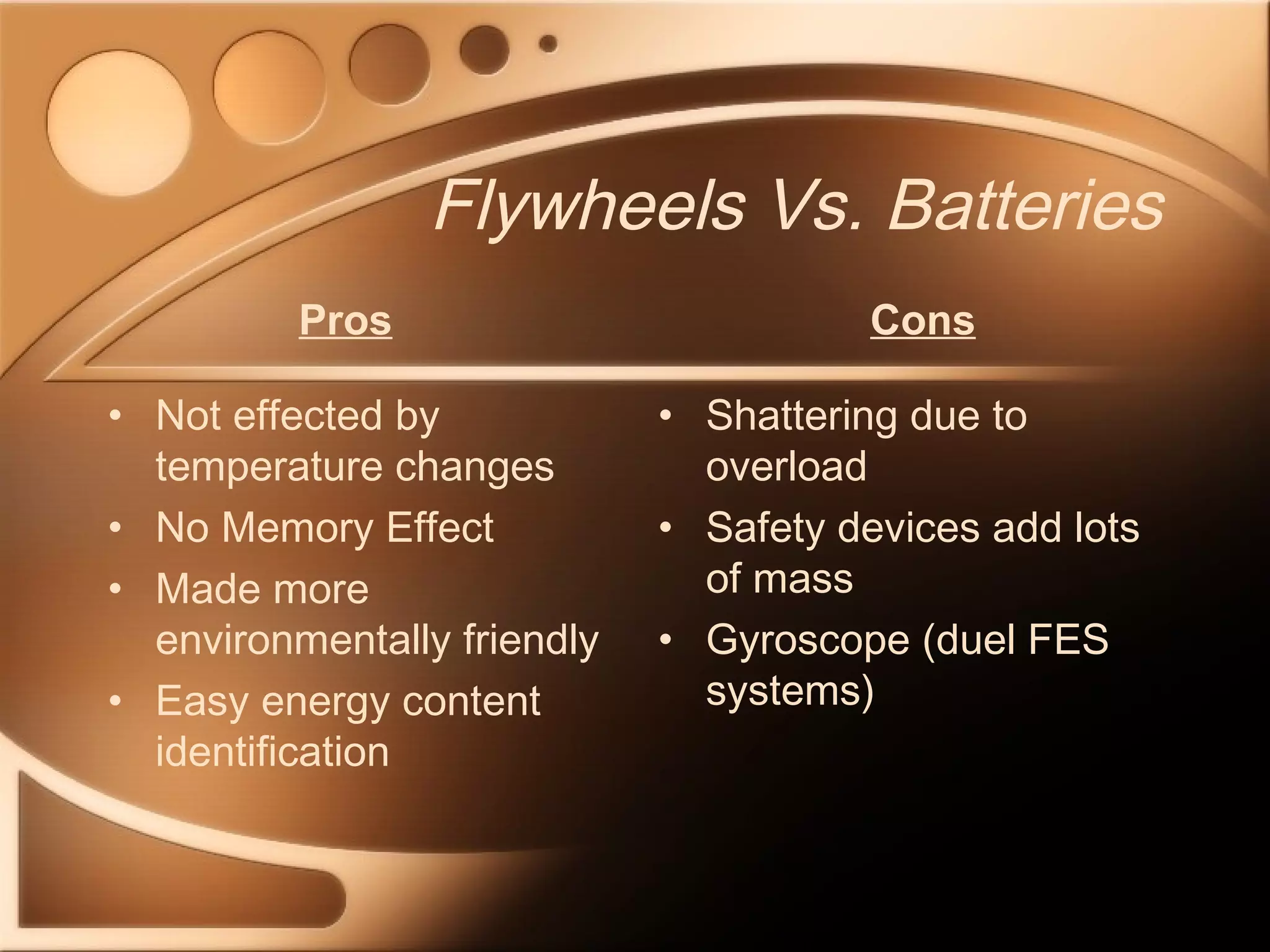

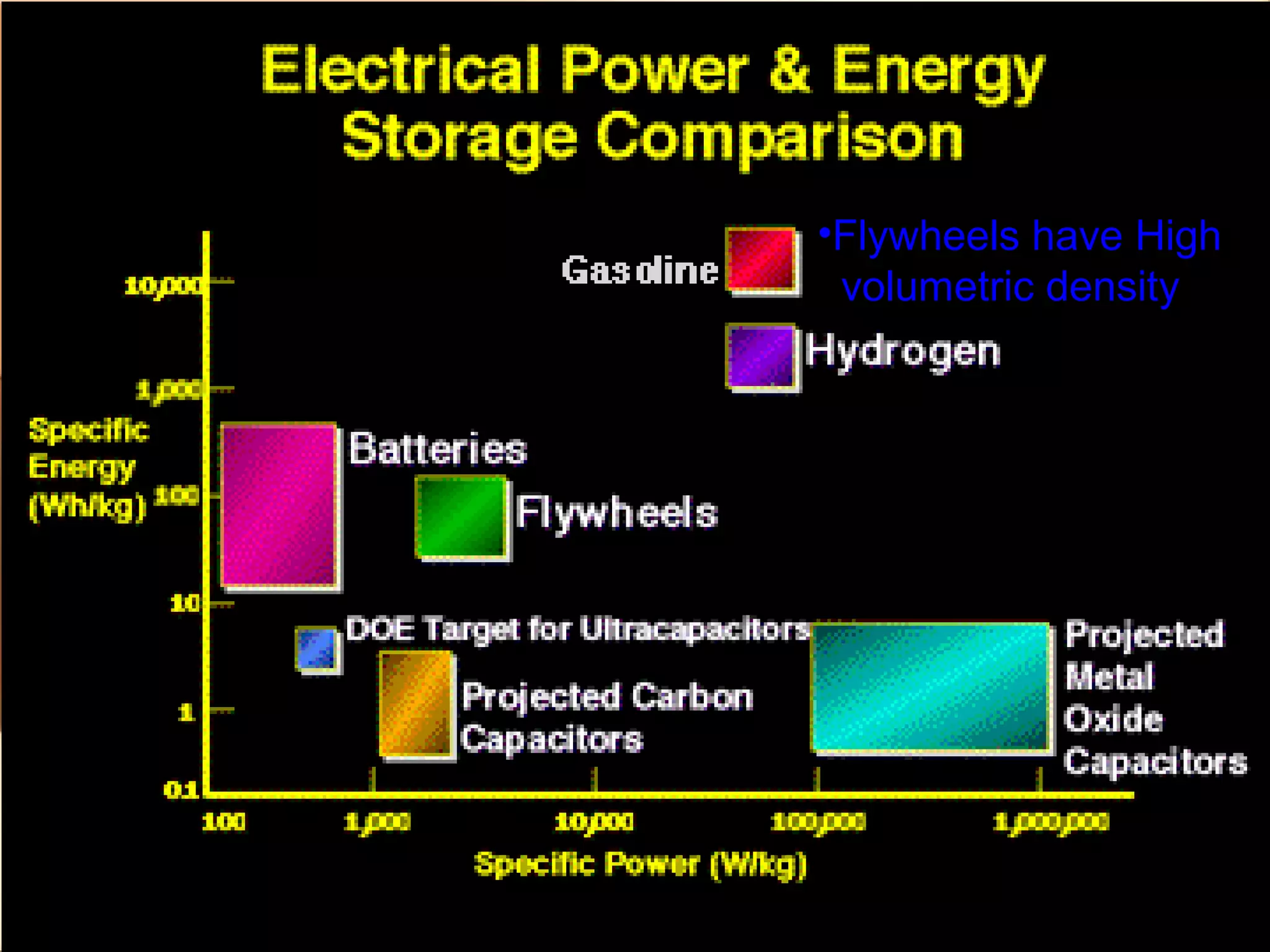

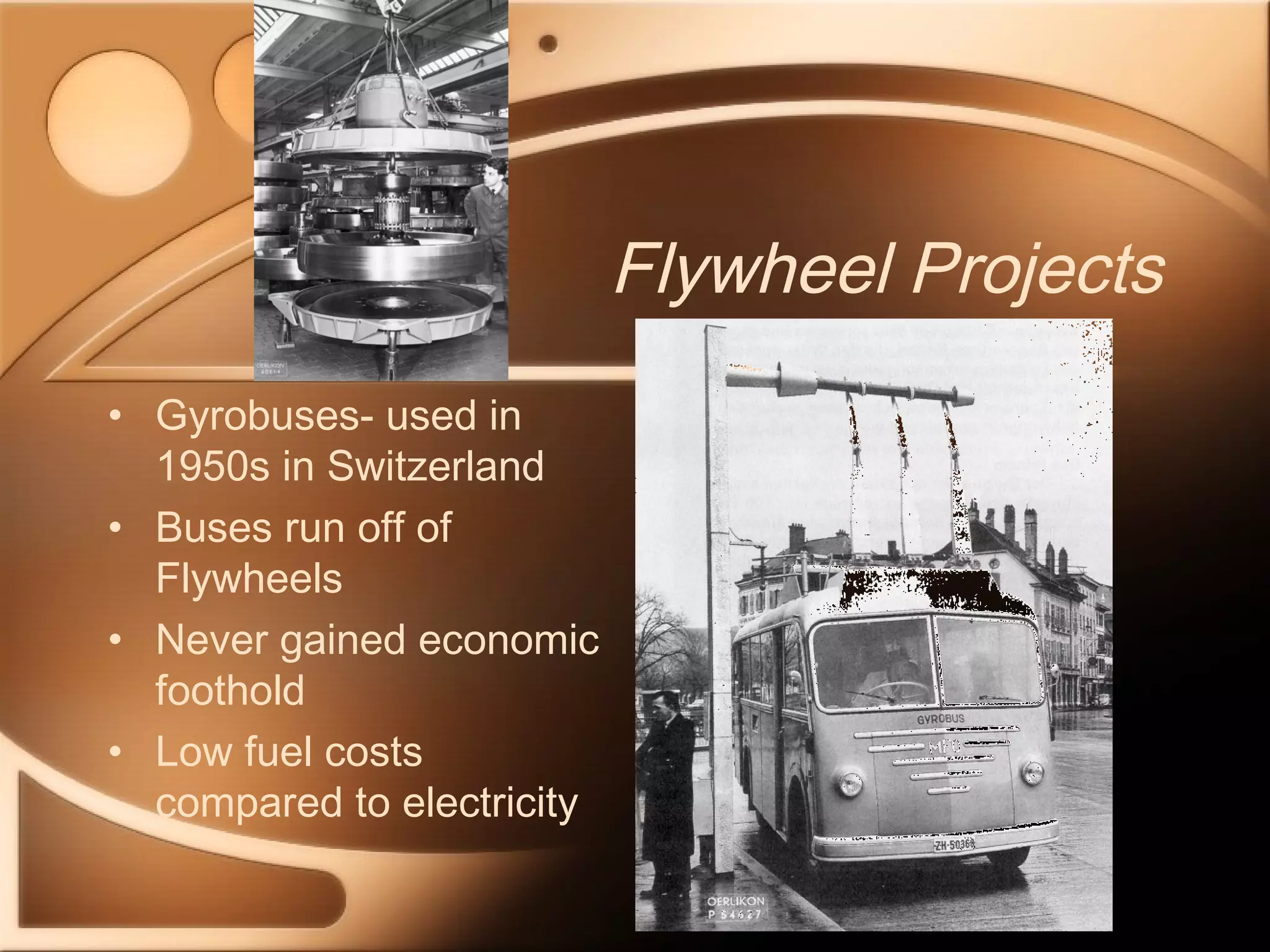

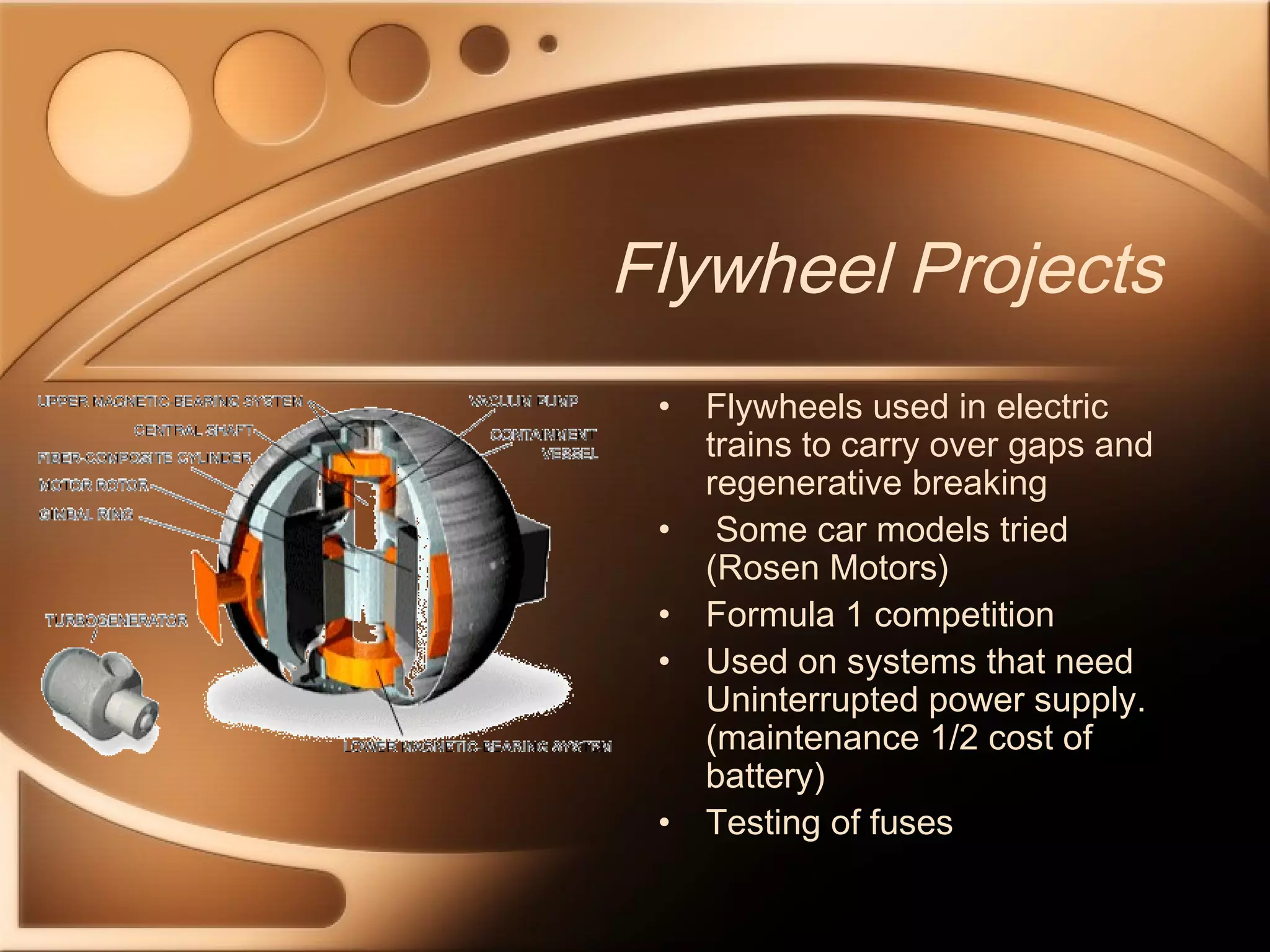

The document discusses three types of mechanical energy storage: pumped hydroelectric storage (PHS), compressed air energy storage (CAES), and flywheels. PHS involves pumping water to a higher elevation and releasing it through turbines to generate power. CAES compresses air underground for later use in power generation. Flywheels store energy kinetically in a spinning rotor. Each technology has benefits like cost-effectiveness (PHS) or ability to help integrate renewable energy, but also challenges such as energy losses or limited locations. Flywheels in particular can have very high cycle life compared to batteries.