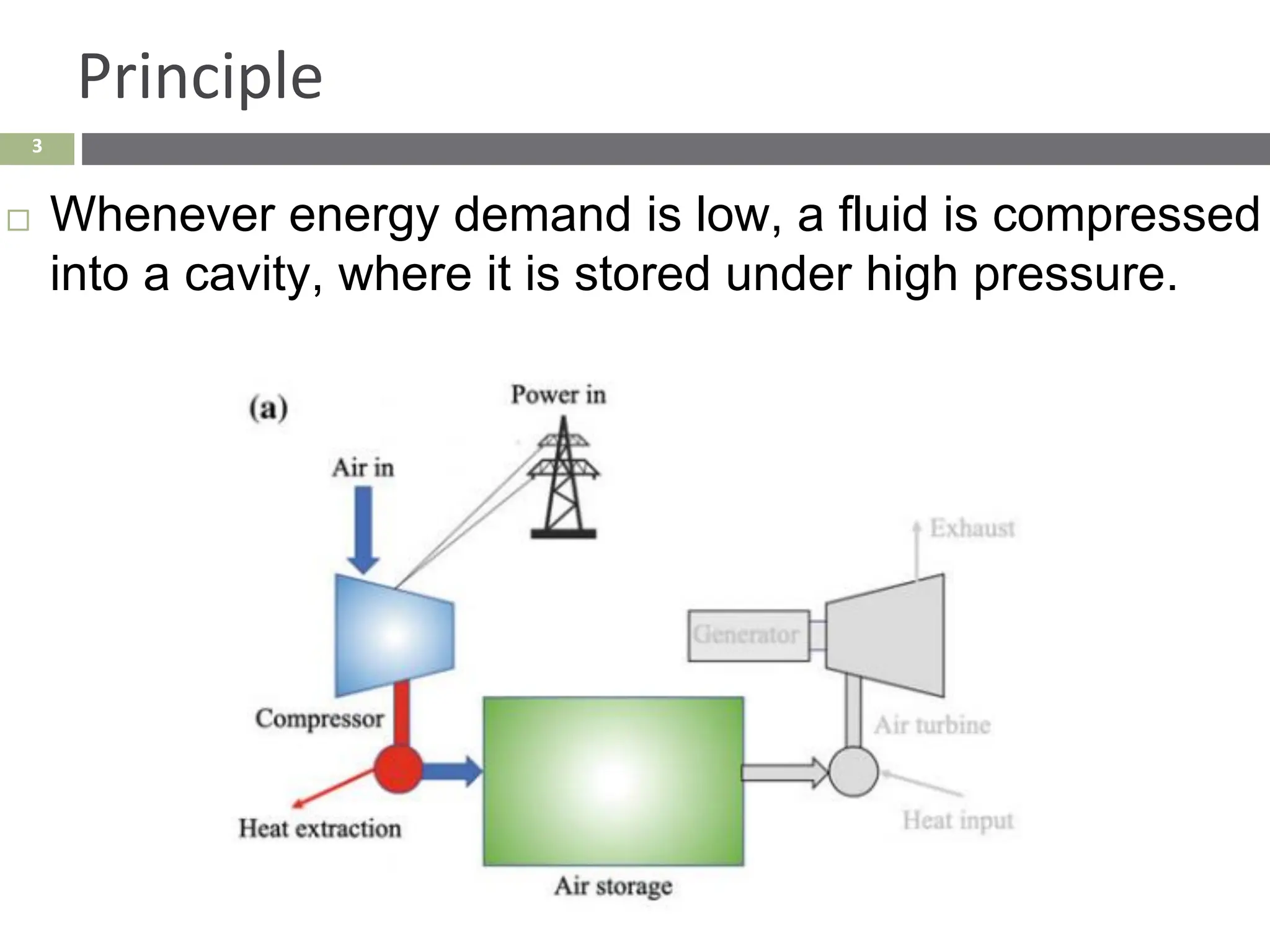

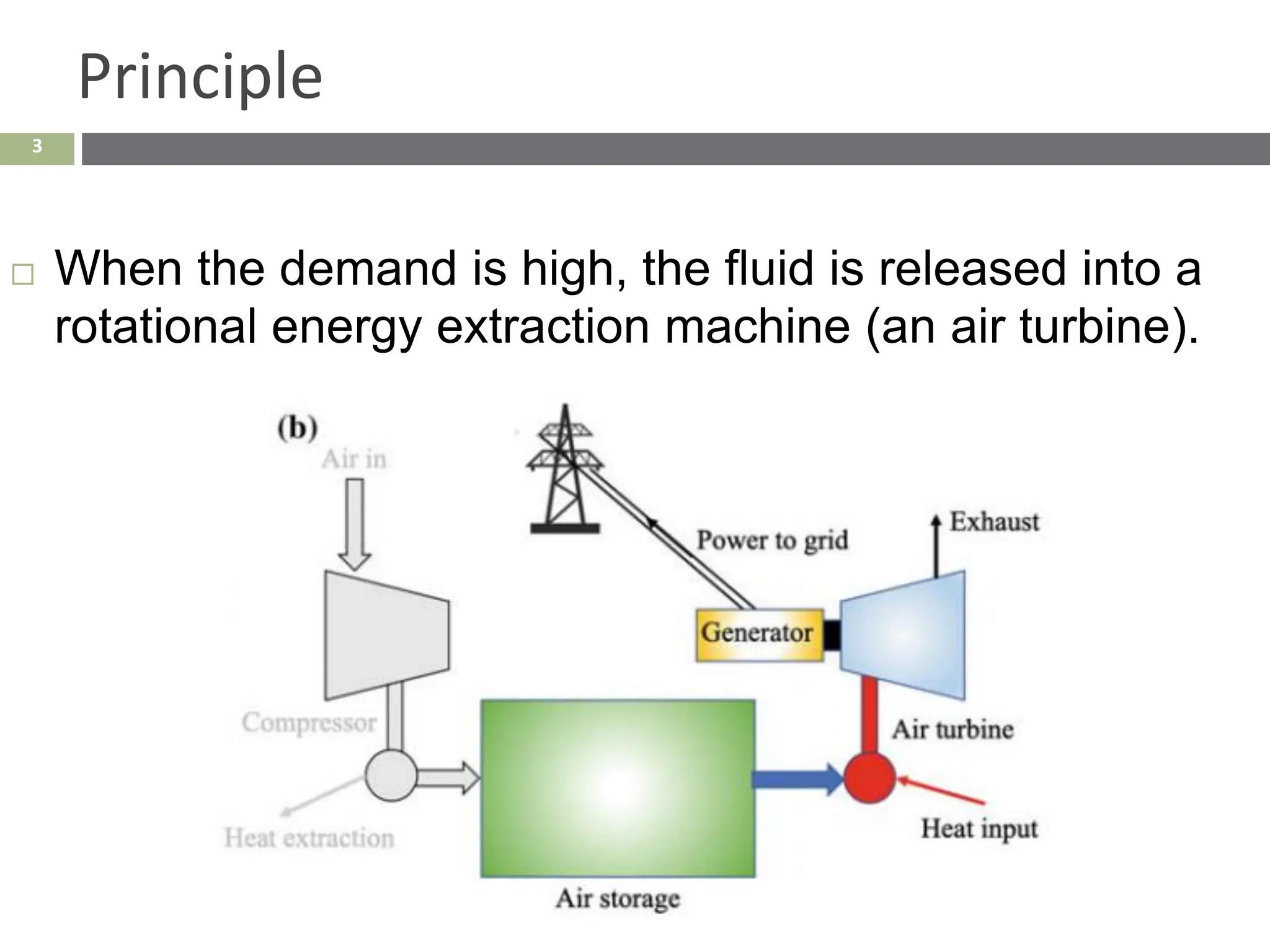

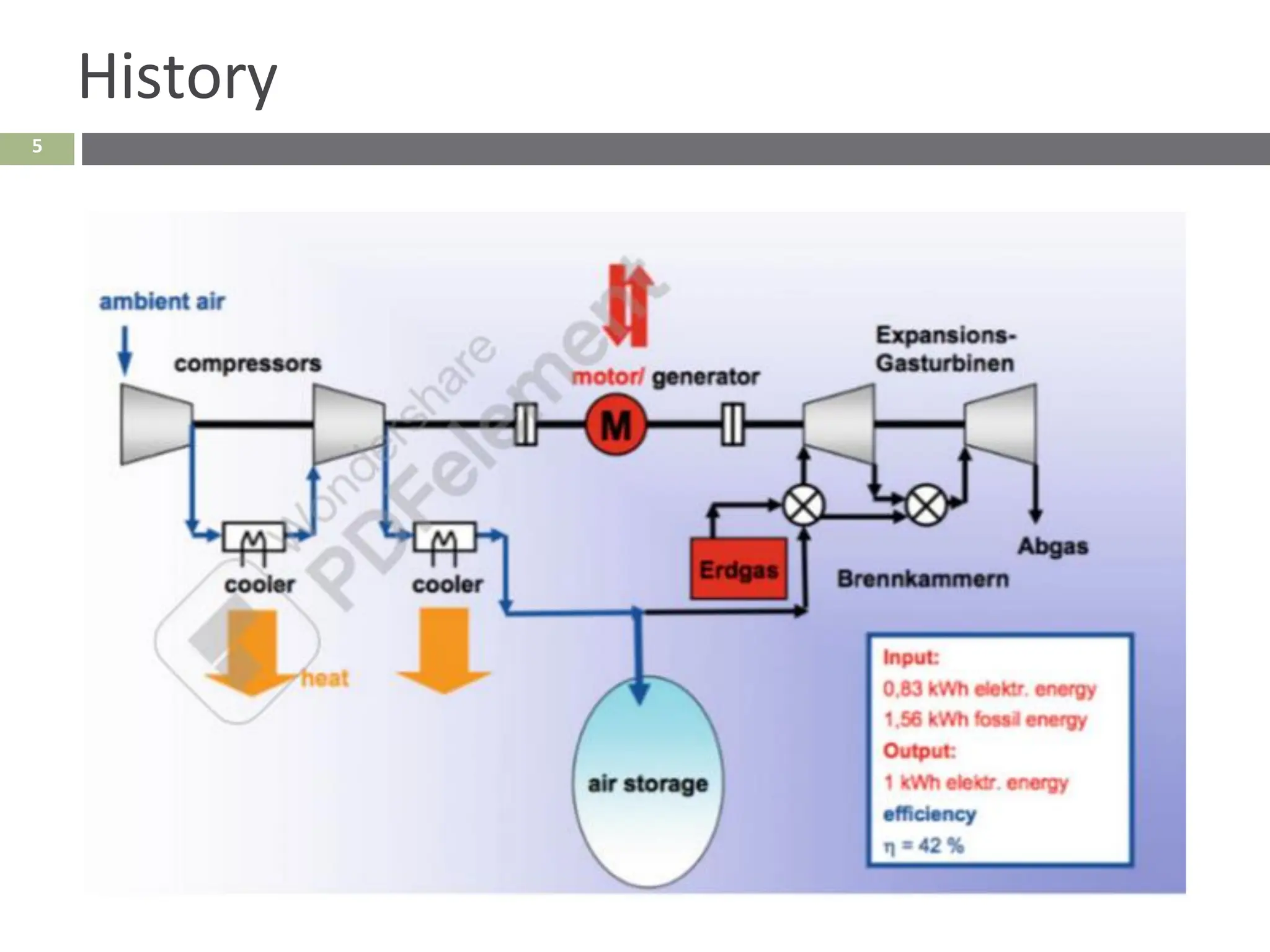

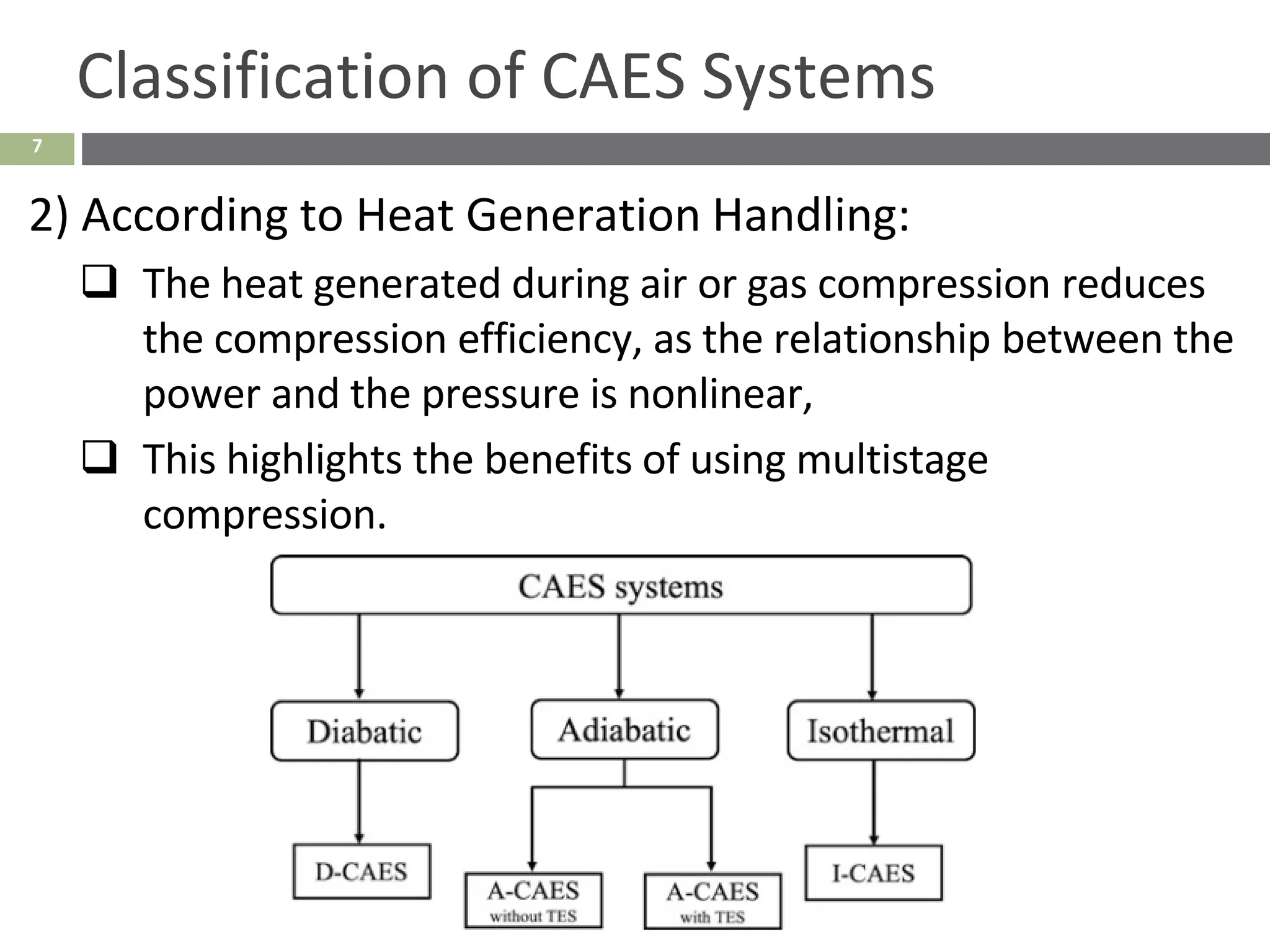

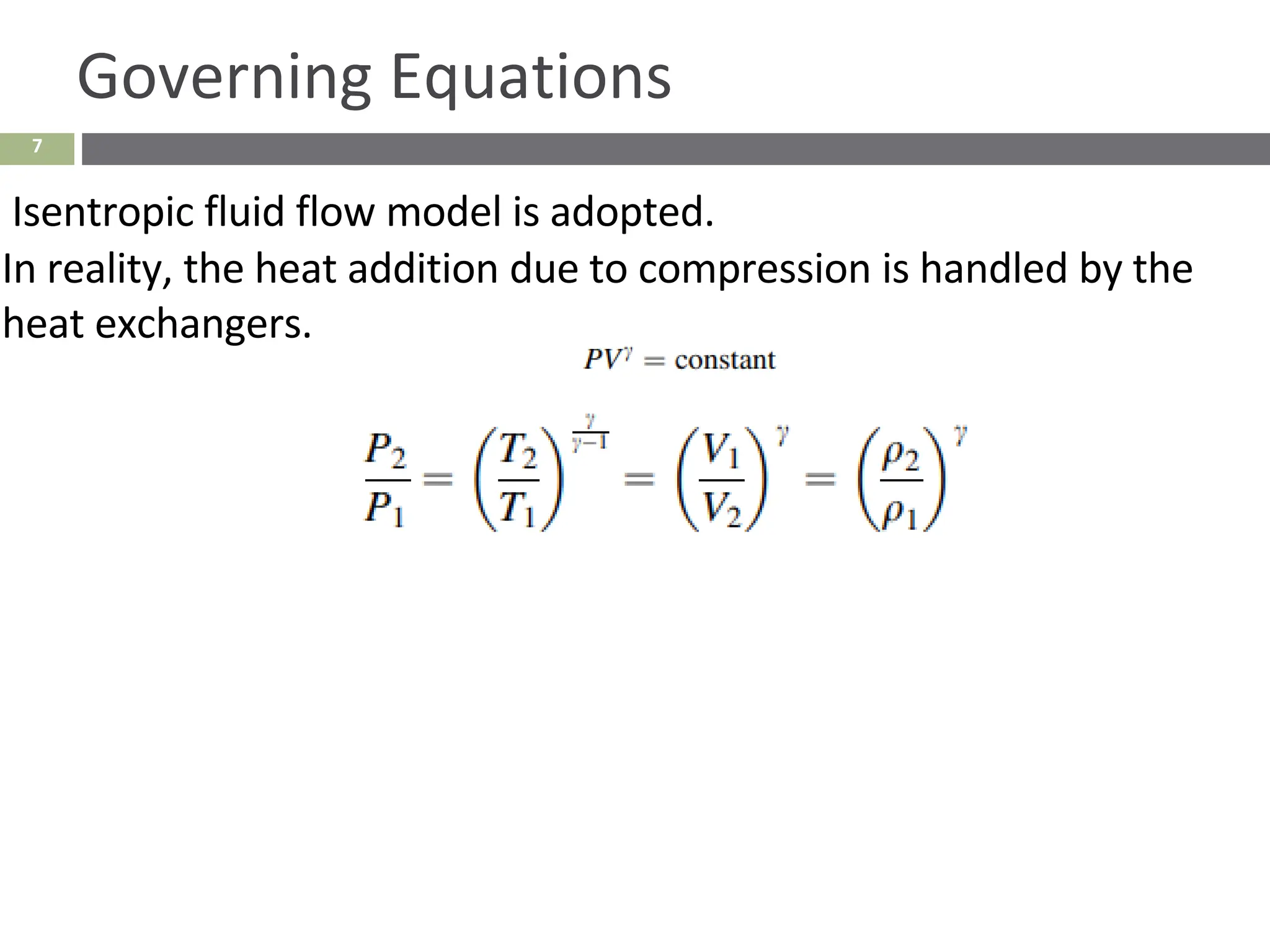

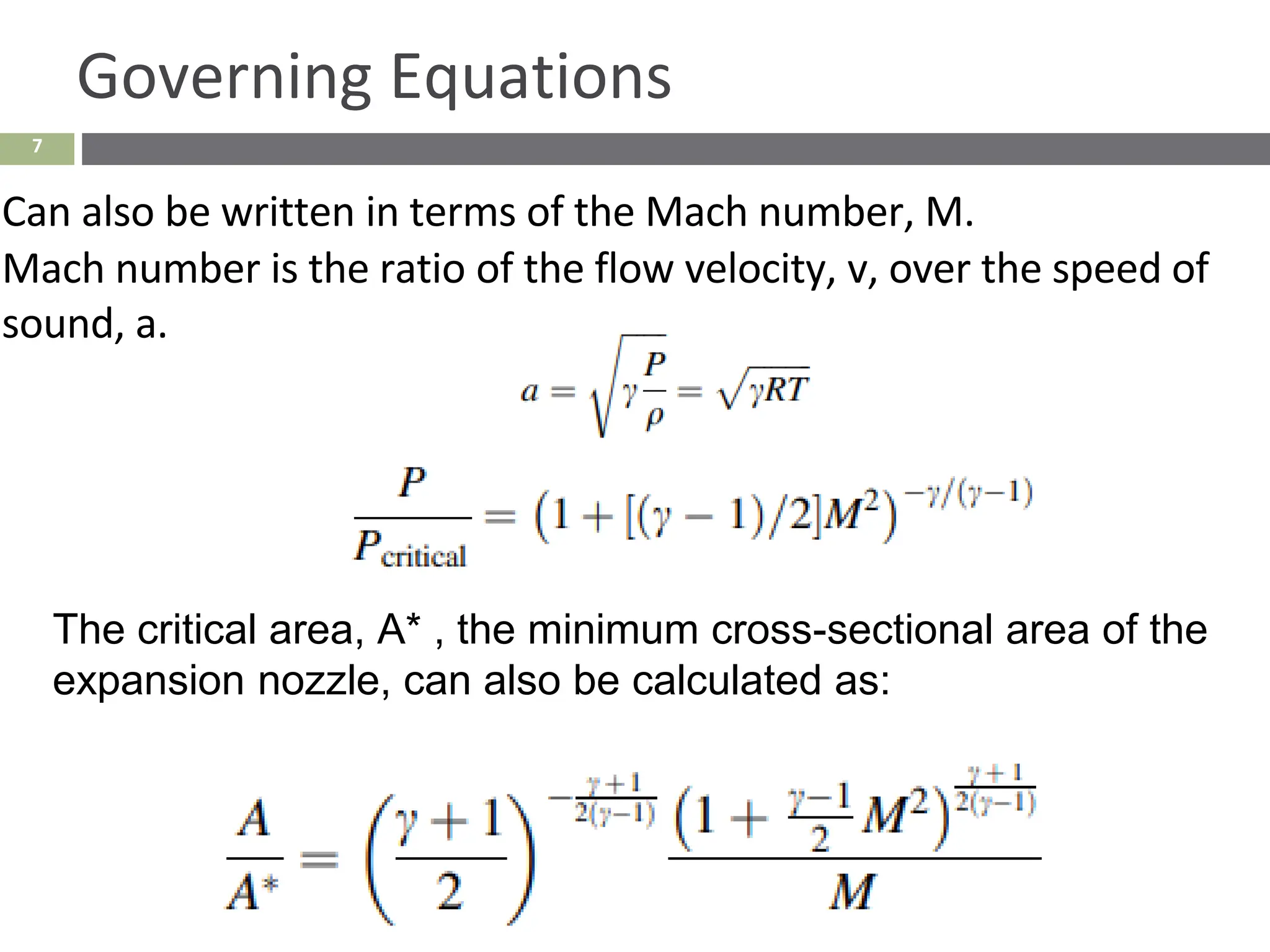

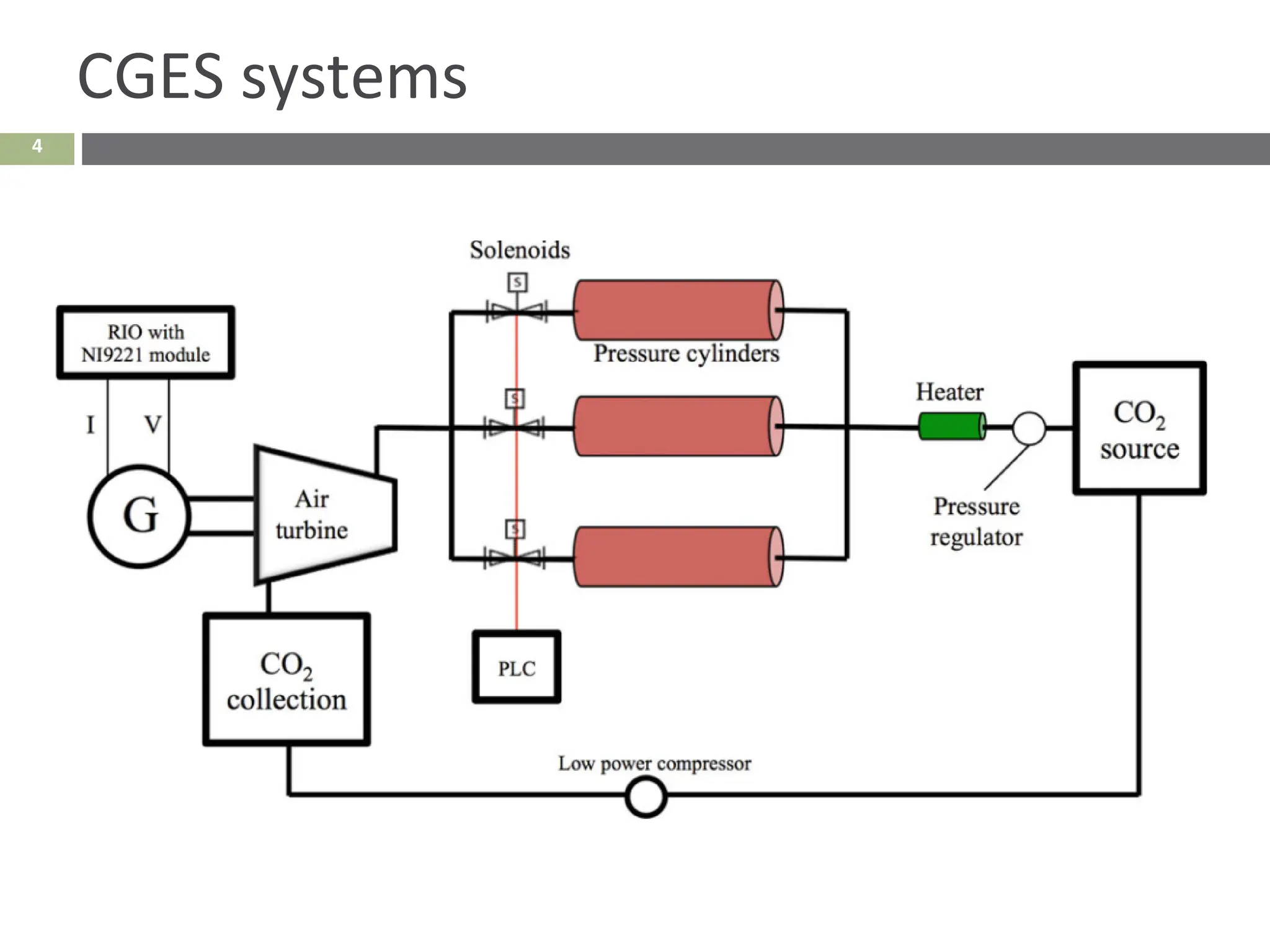

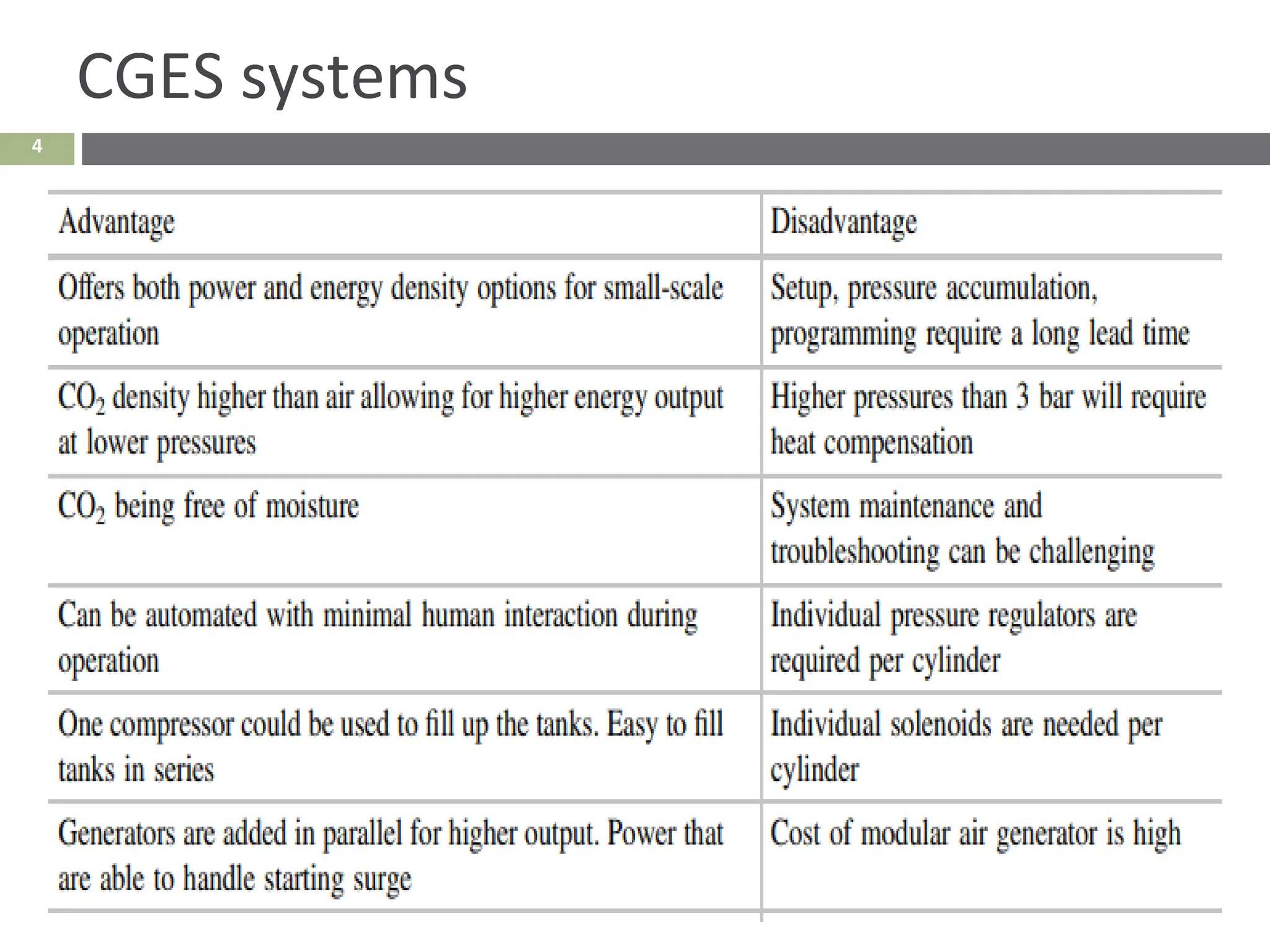

Compressed air energy storage systems store energy by compressing air and storing it in underground reservoirs like depleted gas fields. When energy demand is high, the compressed air is released to drive turbines and generate electricity. There are two main types - diabatic systems that release heat during compression and require external heating for expansion, and adiabatic systems that store heat from compression and use it for expansion. Compressed gas energy storage uses other gases like CO2 instead of air and can couple with CO2 capture benefits.