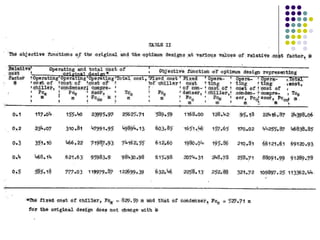

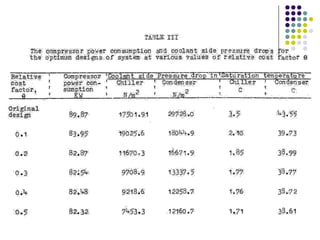

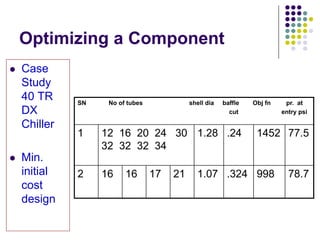

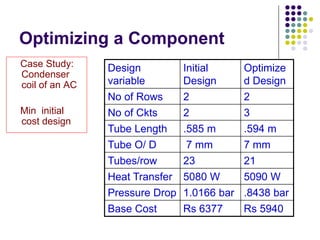

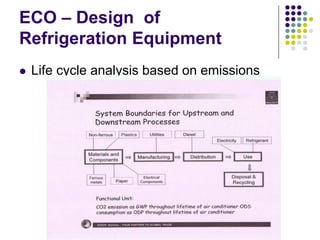

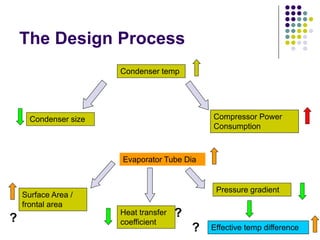

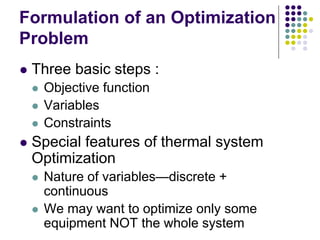

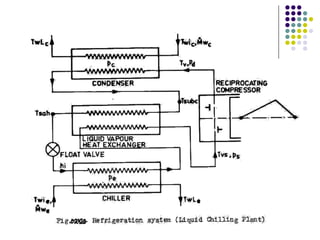

The document discusses the optimization of refrigeration systems, detailing the design process and the need for energy conservation through innovative concepts. It formulates optimization problems, emphasizing the importance of minimizing costs while considering various constraints and system variables. Case studies illustrate the optimization of components like chillers and condenser coils, while also highlighting eco-design principles and energy-saving strategies for air conditioning.

![Optimum Design of a Refrigeration

System -- problem formulation

Min TCs = FCe + FCc + RCe + RCc +Rcco

TCs= ΣNte(i) Lte Cct +Σ Ntc(i) Ltc Cct + [K Mwe PDe +

K Mwc PDc + 0.746 (BHP) ] Ckw Lh

Variables : Lte , Nte( 1,2) ; Ltc , Ntc (1,7)

No of passes, Fin design, tube layout, etc

Constraints: :

Qe = Qer

; Mwe = Mwer, Twic = Twicr ; Qc = Qcr

Max Vel of water < Vr; Tube lengths within bounds](https://image.slidesharecdn.com/optimizationinrefrigerationsystems-140101055157-phpapp02/85/Optimization-in-refrigeration-systems-8-320.jpg)