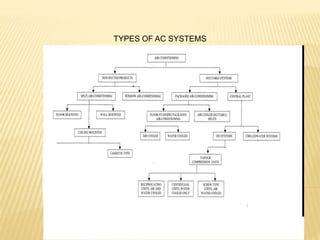

1. There are several types of HVAC systems an architect can choose from for a project, including window AC units, high wall AC units, cassette/ceiling mounted AC units, split systems, variable refrigerant volume (VRV) systems, and centralized AC systems.

2. A centralized AC system has ducts in each room fitted with a fan coil unit (FCU). Each floor has an air handling unit (AHU) and each building has cooling towers mostly on the roof and chillers mostly in the basement to service the entire building.

3. When comparing air cooled split systems, water cooled split systems, air cooled VRV systems, air cooled screw chillers and water cooled screw chillers for

![SYSTEM COMPARISON FOR SERVICES APARTMENTS, RESTAURANTS AND FOOD COURT PROJECT: CONSCIENT ONE DATED: 15 JULY 2013

S No PARAMETER AIR COOLED SPLIT SYSTEM WATER COOLED SPLIT SYSTEM AIR COOLED VRV SYSTEM AIR COOLED SCREW CHILLER WATER COOLED SCREW CHILLER

1 COMPONENTS

Indoor unit. Indoor unit. Indoor unit. Aircooled screw chillers. Watercooled screw chillers.

Aircooled outdoor unit. Watercooled condensing unit. Aircooled outdoor unit. Chilled water pumps. Chilled water pumps.

Refrigerantpiping. Refrigerantpiping. Refrigerantpiping. Chilled water piping. Condenser water pumps.

Cooling towers. Electroniccontrols. Airhandlingunits / Fan coil units. Chilled water piping.

Condenser water pumps. Condenser water piping.

Condenser water piping. Cooling towers.

Air Handling units / Fan coil units.

2 PHASE WISE INSTALLATION Possible Possible Possible Not Possible Not Possible

3 CAPITAL COST L1 L2 H H L3

4

POWER CONSUMPTION HIGH LOW LOW Higher at full load LOW

IKW [Full Load] 1.35 kW/TR 1.1 kW/TR 1.2kW/TR 1.6 kW/TR 1.1 kW/TR

5 OPERATING COST

I

Cooling Requirement at 80%

diversity

382 Tons 382 Tons 382 Tons 382 Tons 382 Tons

IIPower consumption 516 420 459 611 420

6 SPACE REQUIREMENT

IOPEN SPACE for ODUs Required Not Required Required Not Required Not Required

IIOPEN SPACE for PLANT Not Required Not Required Not Required Required Not Required

III

OPEN SPACE for COOLING

TOWERS

Not Required

Required.[for condenser pumps

also]

Not Required Not Required Required

IVBASEMENT SPACE for PLANT Not Required Not Required Not Required Not Required Required

7 REFRIGERANT PIPING Length less than 15 m. Required Length 50m-100m. NA NA

8 BILLING Easiest

Easy, only cooling towers and

pumps are common.

Easy, in case of separate system for

each user.

Difficultdue to common plant Difficultdue to common plant

9 DERATION

High in peak ambient

conditions

Low in peak ambient conditionsHigh in peak ambient conditions High in peak ambient conditions Low in peak ambient conditions

10

SOFT WATER REQUIREMENT NA 8LPH/TR NA NA 8LPH/TR

TOTAL WATER

REQUIREMENT/DAY (12

HOURS)

NA 36710 LITRES/DAY NA NA 36710 LITRES/DAY

11 RECOMMENDATIONS

Not recommendeddue to non

availability of open spaces for

ODUs

Recommended for best

efficiencyand low capex if

water is not scarce.

Not recommendeddue to non

availability of open spaces for ODUs

Recommended due to water scarcity

and good performanceon part loads.

Recommended for best efficiency

and low capex if water is not scarce.](https://image.slidesharecdn.com/2-150830095159-lva1-app6891/85/BS5-Lecture-2-HVAC-Systems-14-320.jpg)