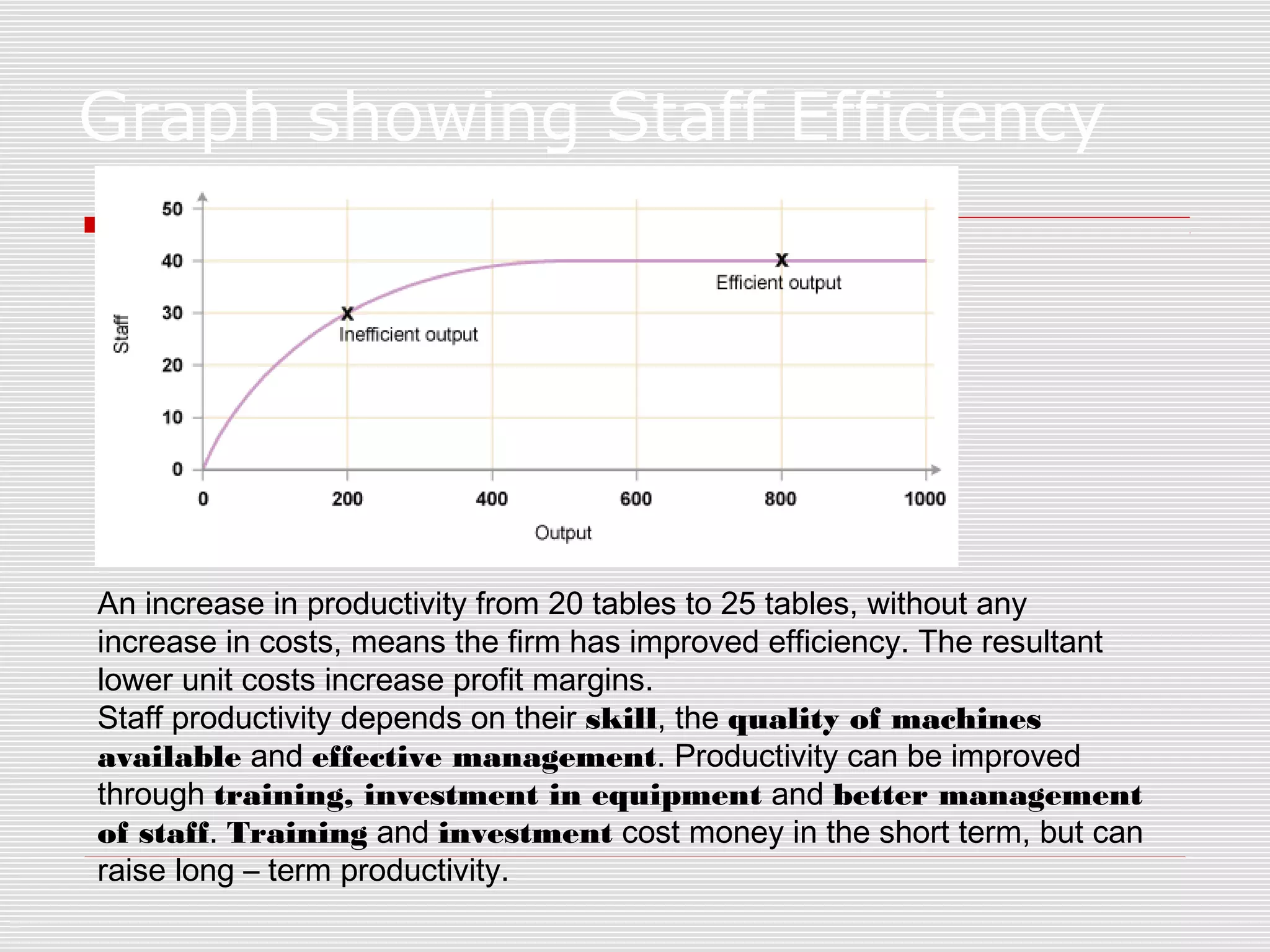

The document discusses key concepts related to efficiency in business. It begins by explaining that efficiency, productivity, and competitiveness are linked, as better productivity leads to increased efficiency and competitiveness. It then defines efficiency as making the best use of resources to maximize outputs and minimize costs. Improving efficiency can reduce costs and improve competitiveness. The document also differentiates between production and productivity, and provides an example to demonstrate how to calculate productivity. It explains that productivity can be improved through training, investment, and better management. Finally, it outlines other methods businesses can use to cut costs besides improving productivity.