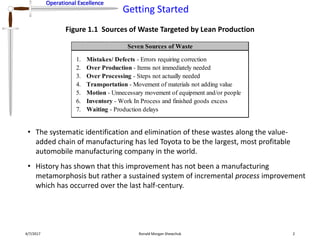

- The document discusses the origins and development of Lean manufacturing and Six Sigma processes at Toyota Motor Company in the 1950s as they struggled with limited resources. Engineers Taiichi Ohno and Shigeo Shingo developed the Toyota Production System (TPS) to reduce waste and increase efficiency.

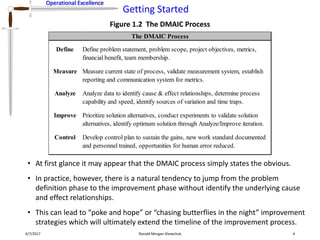

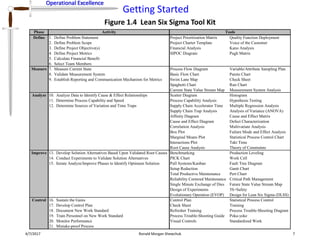

- TPS and Six Sigma methodology focus on reducing defects and process variation to improve quality and efficiency. When implemented together as Lean Six Sigma, they provide a systematic approach to continuous process improvement.

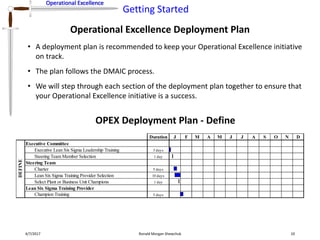

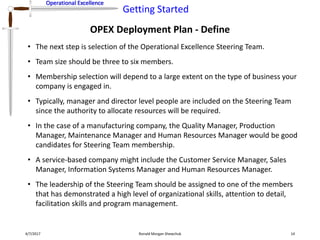

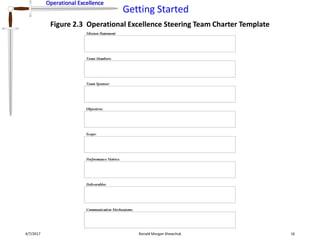

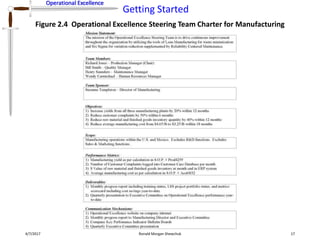

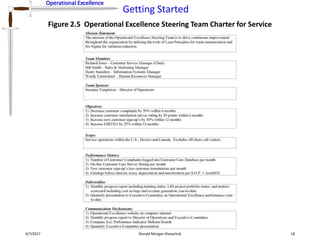

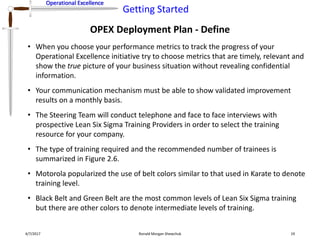

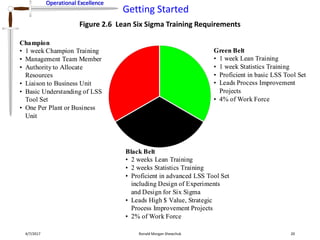

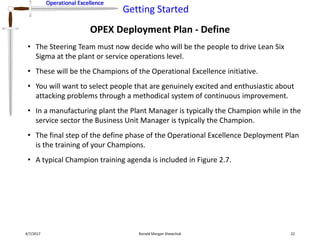

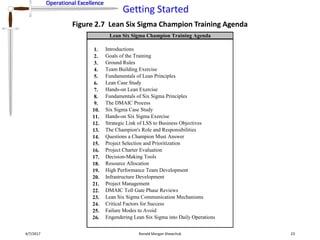

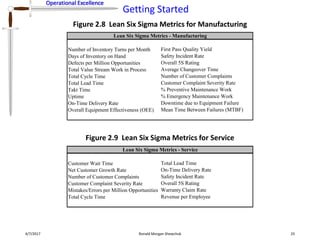

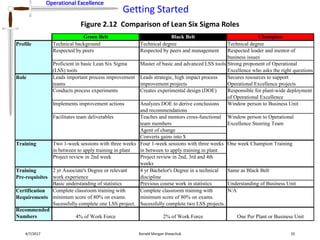

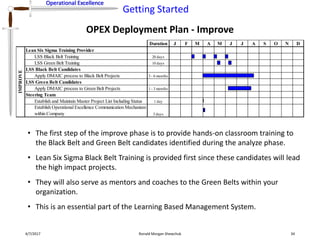

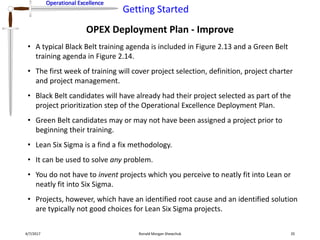

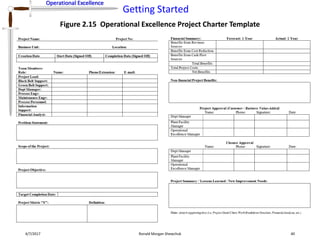

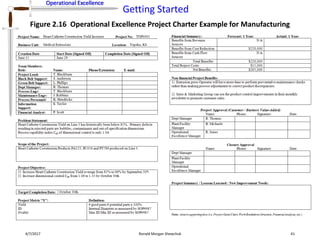

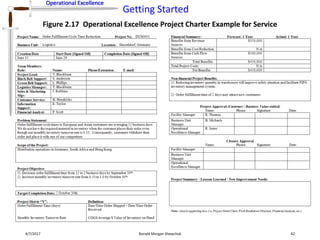

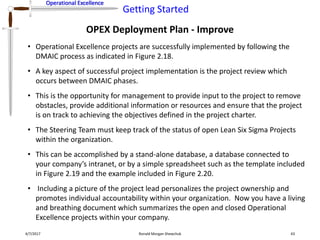

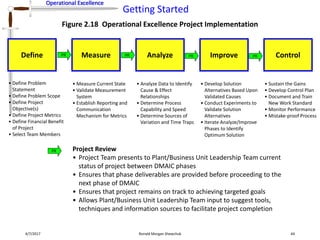

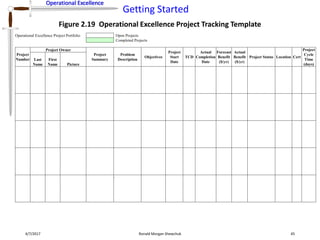

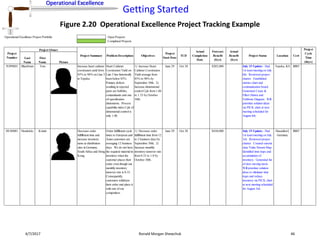

- Lean Six Sigma can be applied to manufacturing and service industries to reduce waste and improve processes in order to increase customer satisfaction and cost savings. The document outlines a sample deployment plan to implement Lean Six Sigma at an organization.